By quanyu lee

2025-04-16 01:25:15

PVC and TPU sheaths for automotive wiring harnesses

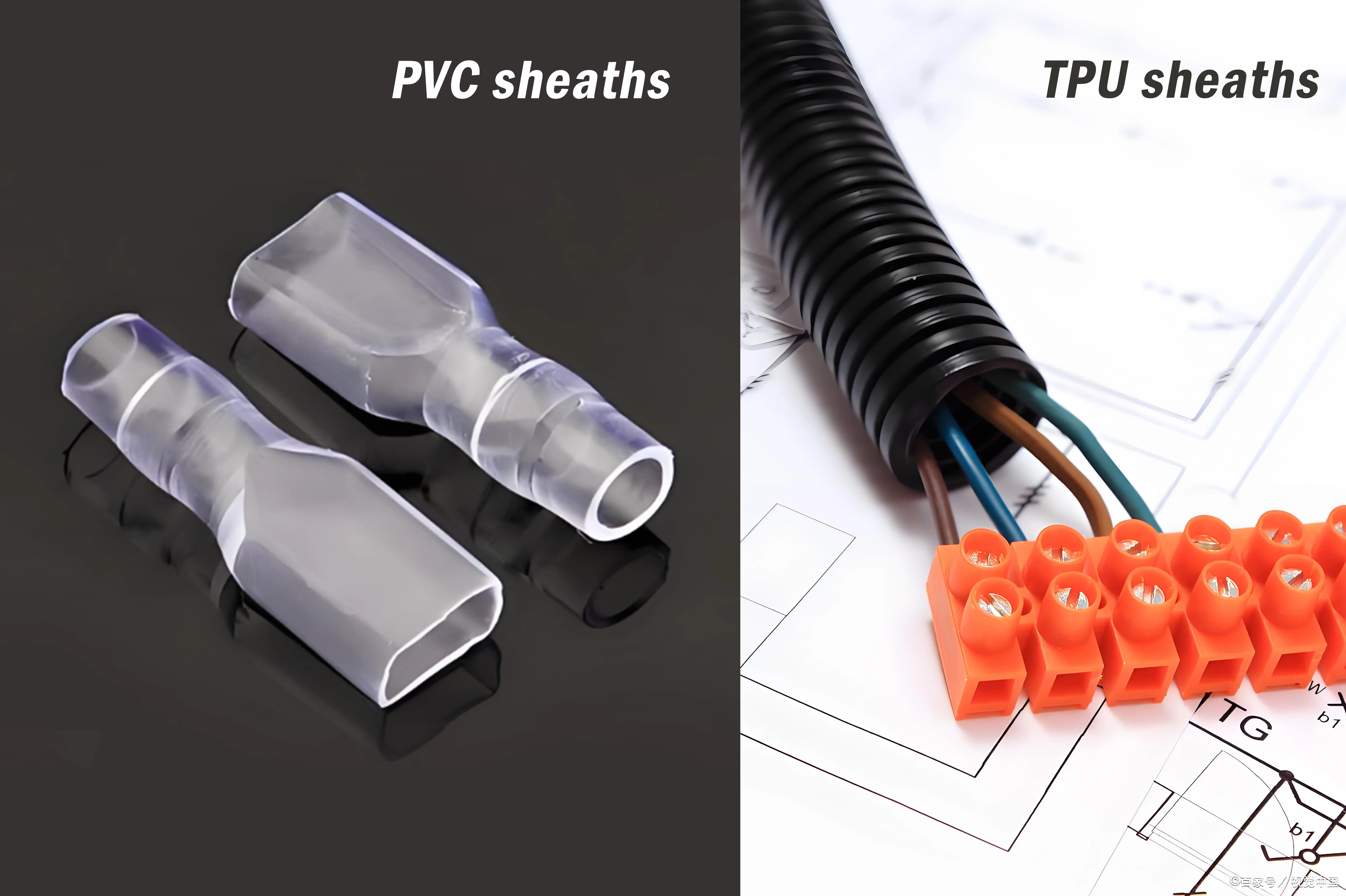

What are PVC and TPU sheaths for automotive wiring harnesses?

PVC jacket (polyvinyl chloride)

A plastic material made by polymerizing vinyl chloride monomer, with plasticizer added to enhance flexibility. Its advantages are low cost and good wear resistance, but poor temperature resistance (-40℃~105℃) and long-term use may release volatile organic compounds (VOCs).

TPU jacket (thermoplastic polyurethane)

Made of high molecular polyurethane elastomer, it has both the flexibility of rubber and the strength of plastic. It has a wider temperature resistance range (-60℃~125℃), a tear strength of 35N/mm², and does not contain harmful substances such as VOCs.

Parameter comparison of PVC and TPU sheath

| Index | PVC sheath | TPU sheath |

| Material Nature | Plastic (mainly rigid) | Rubber (mainly elastic) |

| Temperature resistance | -40℃~105℃ (prone to high temperature deformation) | -60℃~125℃ (strong light and heat stability) |

| Tear strength | 15N/mm² (easy to break) | 35N/mm² (rebound after stretching) |

| Environmental protection | May contain VOCs | Non-toxic and odorless, in line with environmental protection standards |

| Service life | 3-5 years (prone to yellowing and cracking) | 8-10 years (excellent anti-aging performance) |

How to quickly distinguish between PVC and TPU?

Hardness test: PVC is stiff, TPU is soft and droopy;

Stretching test: TPU can be stretched to twice its length and rebound, PVC is easy to break; Burning ash: PVC turns black after burning, TPU is light yellow or transparent.

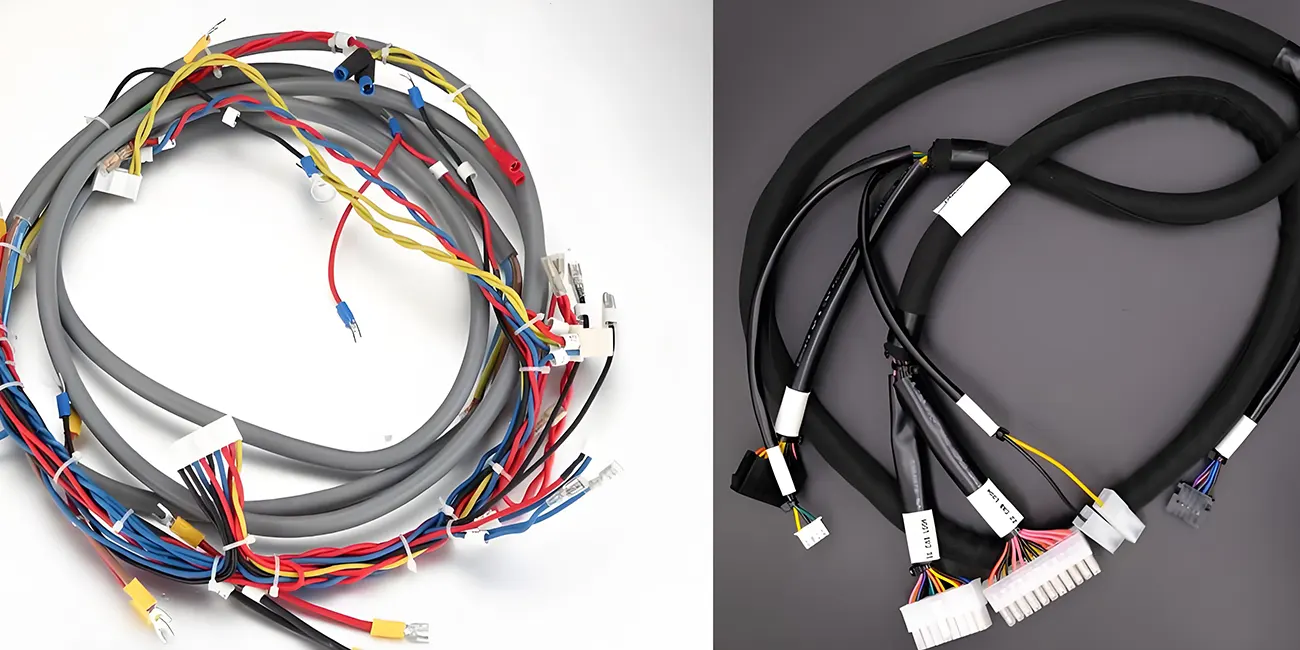

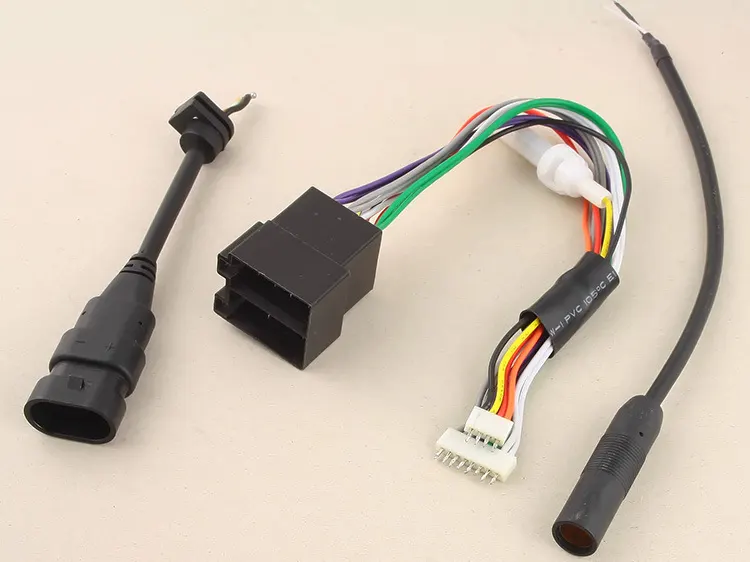

Typical application scenarios

PVC sheath is preferred:

Low-voltage wiring harness (such as car audio, lighting system)

Cost-sensitive models (conventional wiring harness for family cars)

TPU sheath must be used:

High-voltage battery wiring harness (such as 900V system for electric vehicles)

Extreme environments (vehicles in cold/high temperature areas)

Summary: PVC sheaths are suitable for conventional scenarios with low cost and basic protection capabilities, while TPU sheaths are the first choice for high-end automotive wiring harnesses due to their weather resistance, environmental protection and long life.