By quanyu lee

2025-07-28 08:42:30

Wire Harness Material Guide for Extreme Environments

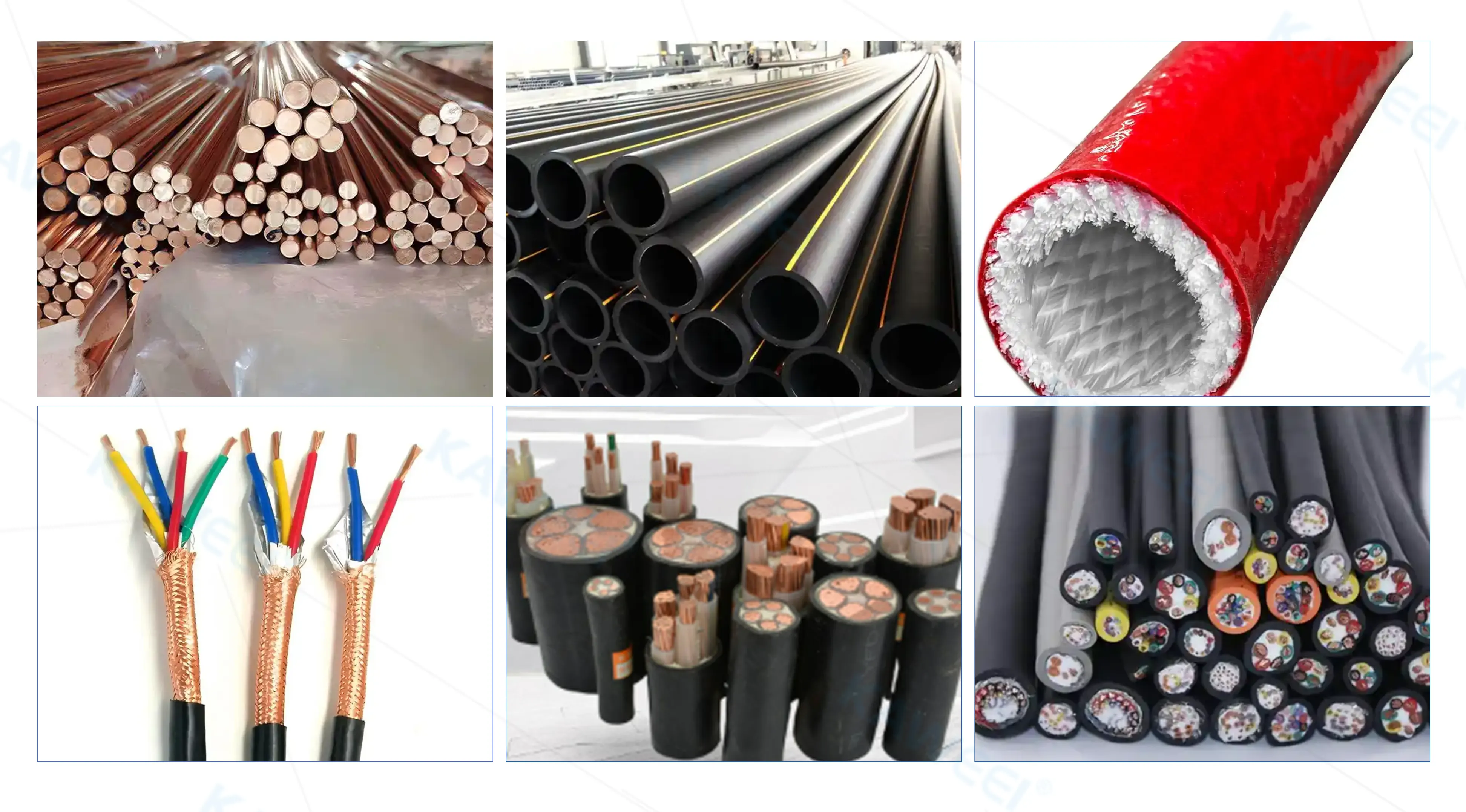

In the design and manufacturing of wire harnesses, the selection of suitable wire harness materials directly impacts their reliability, performance, and service life. Different working environments—such as high temperature, low temperature, chemical exposure, mechanical wear, and electromagnetic interference (EMI)—require specific material configurations. This article will analyze in detail the selection method of wire harness materials based on the environmental conditions encountered during wire harness use.

1. High Temperature Resistant Wire Harness Materials

In environments above 120°C, conventional wire harnesses are prone to insulation degradation, oxidation, and melting sheaths. Choosing the right high temperature wire harness ensures long-lasting performance.

Recommended Materials:

- Conductor: Tinned copper, silver-plated copper, or nickel-chromium alloy (for temperatures above 200°C).

- Insulation: Cross-linked PVC (XLPE), Polyimide (PI), or PTFE (resistant up to 260°C).

- Sheath: Fluororubber (FKM) or Polyamide (PA) for heat and aging resistance.

Typical Solutions:

- FLRY series cable: Tinned copper + XLPE insulation (135°C).

- Polyimide enameled wire: PI insulation + silver-plated copper conductor (250°C).

- PTFE wire: Nickel-plated copper + PTFE insulation (260°C).

2. Low Temperature Wire Harness Materials for Cold Weather Use

Temperatures below -40°C can make materials brittle and crack-prone. A low temperature wire harness must retain flexibility and conductivity under extreme cold.

Recommended Materials:

- Conductor: Soft oxygen-free copper.

- Insulation: Cross-linked polyethylene (XLPE), polyurethane (PU), or silicone.

- Sheath: Thermoplastic polyurethane (TPU) or EPDM rubber.

Typical Solutions:

- AVSS cable: Cold-resistant PVC + soft copper (brittle point < -40°C).

- XLPE/TPU combo: Operates reliably at -50°C, ideal for cold chain vehicles.

- EPDM-sheathed cable: For outdoor power transmission in polar conditions.

3. Chemical Resistant Wire Harness for Harsh Chemical Environments

Exposure to acids, alkalis, salt spray, and oils causes swelling, cracking, and conductor corrosion. A chemical resistant wire harness is essential in marine, laboratory, and industrial plant applications.

Recommended Materials:

- Conductor: Silver-plated or nickel-plated copper.

- Insulation: PTFE, ETFE.

- Sheath: FKM rubber, LSZH (Low Smoke Zero Halogen), neoprene.

Typical Solutions:

- PTFE-insulated cable: Excellent resistance to acid, alkali, and solvents.

- FKM cable: FKM sheath + ETFE insulation, ideal for engine compartments.

- LSZH-sheathed cable: Nickel-plated copper + weather-resistant jacket.

4. Mechanical Wear-Resistant Wire Harness for High-Stress Applications

Wire harnesses in robots, machinery, and vehicles face bending, vibration, and friction. A mechanical wear resistant wire harness must endure constant movement and physical impact.

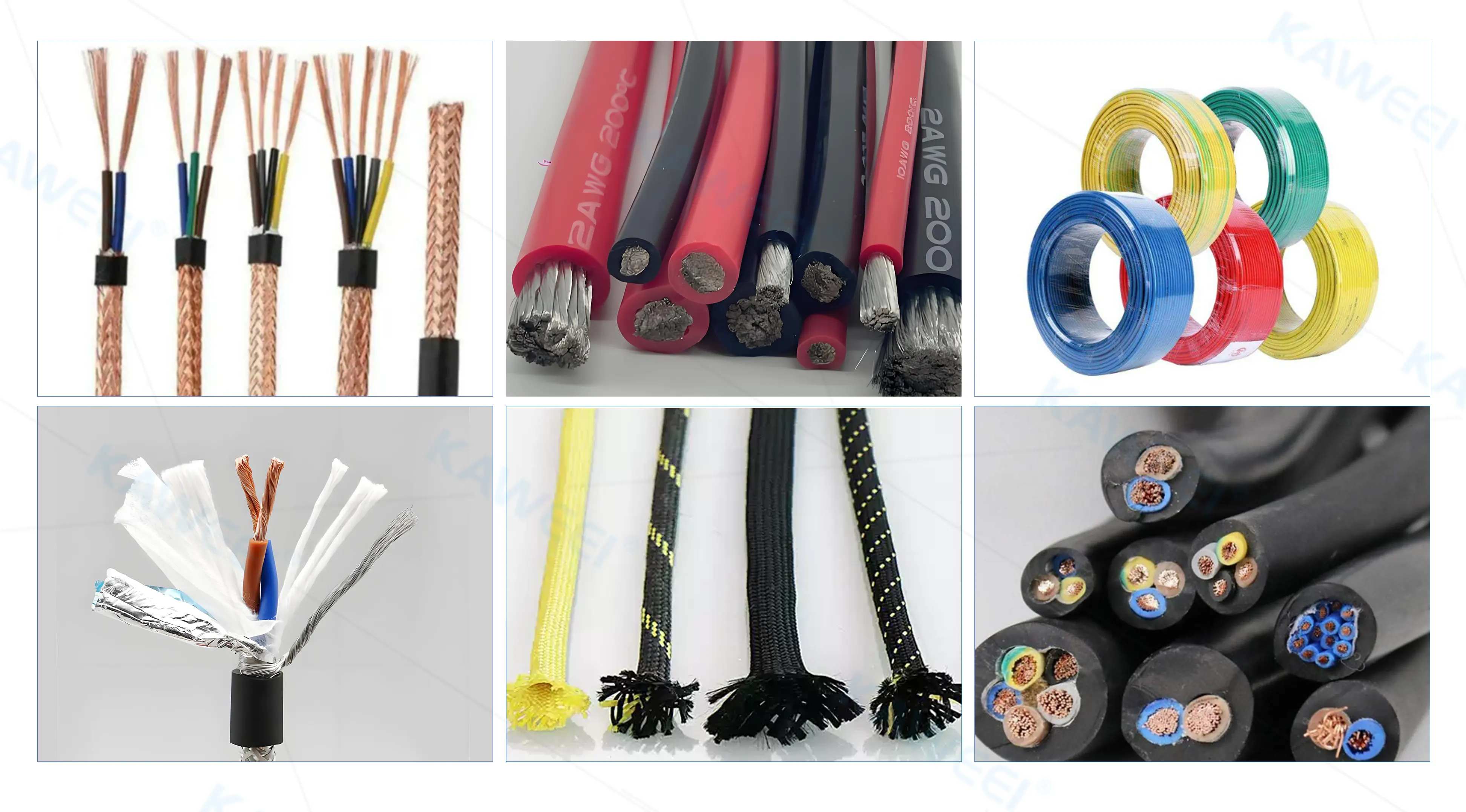

Recommended Materials:

- Conductor: Ultrafine stranded copper for flexibility and fatigue resistance.

- Insulation: Silicone or PU.

- Sheath: Polyurethane (PUR), polyamide (PA), or aramid-reinforced sheath.

Typical Solutions:

- Robot drag chain cable: Silicone insulated + PUR sheathed + ultrafine copper.

- Aramid-braided cable: For mining or construction, improved tensile strength.

- Vibration-resistant cable: Multi-strand PU insulated, PUR sheathed.

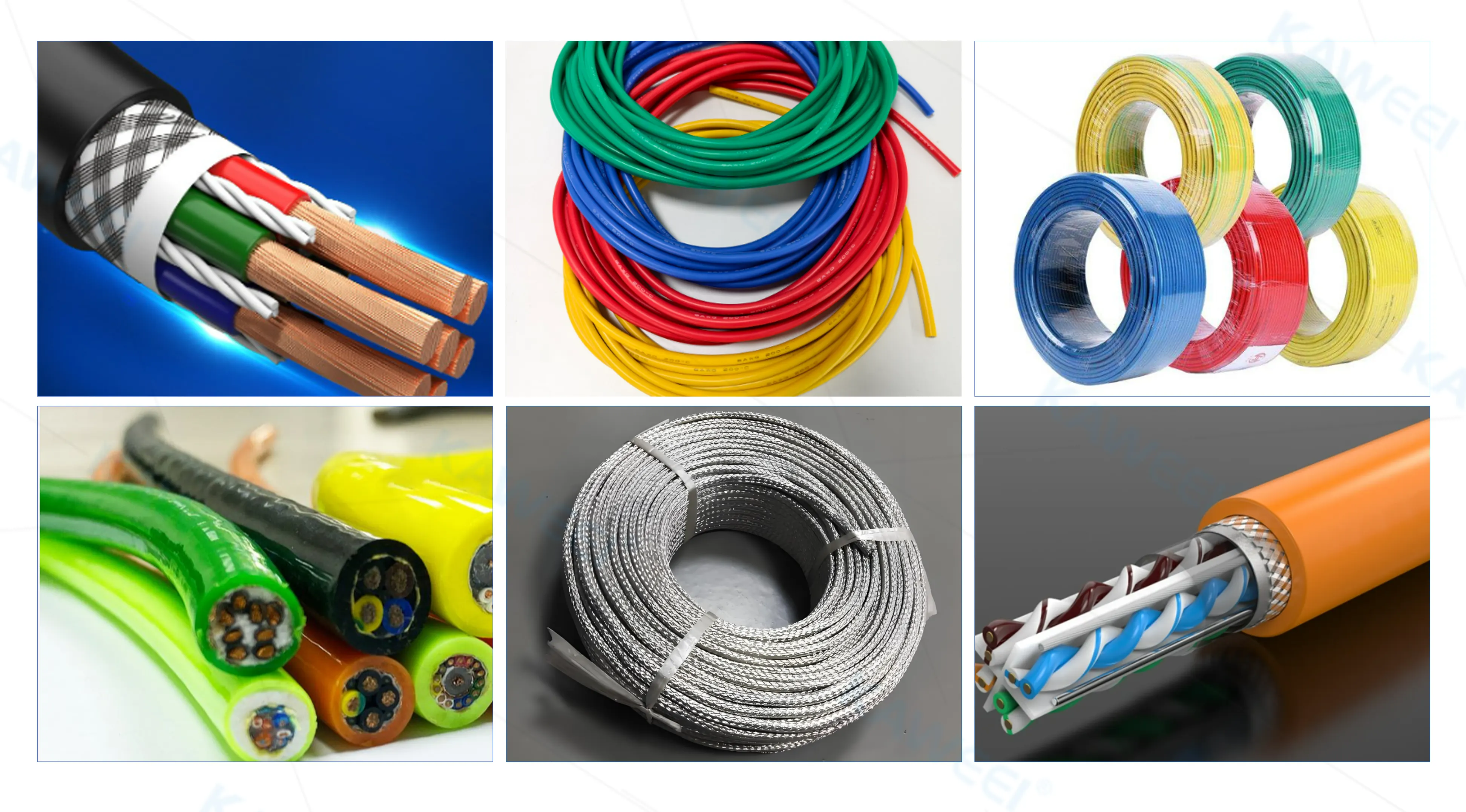

5. EMI Shielded Wire Harness for Signal Protection

In environments with electromagnetic interference, signal distortion and transmission failure are common. A properly shielded wire harness preserves communication integrity.

Recommended Materials:

- Conductor: High-purity oxygen-free copper (OFC).

- Insulation: Foamed PE or PTFE with low dielectric loss.

- Shielding: Copper foil, aluminum foil, or copper wire braid.

Typical Solutions:

- Copper foil + braided cable: OFC + dual shielding (≥80dB), ideal for automotive Ethernet and USB4.0.

- Double-shielded EMI cable: Inner aluminum foil + outer copper braid.

- <LFSH cable: For hospitals and offices with high EMI sensitivity.

6. Recommended Material Combinations by Environment

| Environment | Recommended Configuration |

| High Temp (150–260°C) | Nickel-chromium conductor + PI or PTFE insulation + FKM sheath |

| Low Temp (<-40°C) | Ultrafine copper + silicone insulation + EPDM sheath with aramid |

| Chemical Exposure | Titanium alloy conductor + PTFE insulation + FKM sheath |

| Mechanical Stress | Ultrafine stranded copper + silicone + aramid-reinforced PUR |

| EMI Environment | 7N OFC + PTFE + copper foil + tinned copper braided shield |

Choosing the right wire harness material ensures product performance, safety, and cost-efficiency. Whether you need high-temperature cables, low-temperature wire harnesses, or EMI shielded cable assemblies, Kaweei wiring harness customization factory can provide high-quality wiring harness solutions for complex environments. If you need customized wiring harnesses, please get in touch with us.