By quanyu lee

2025-12-06 11:33:47

AWG Wire Harness Guide: How to Select the Right Wire Gauge for Different Currents and Applications

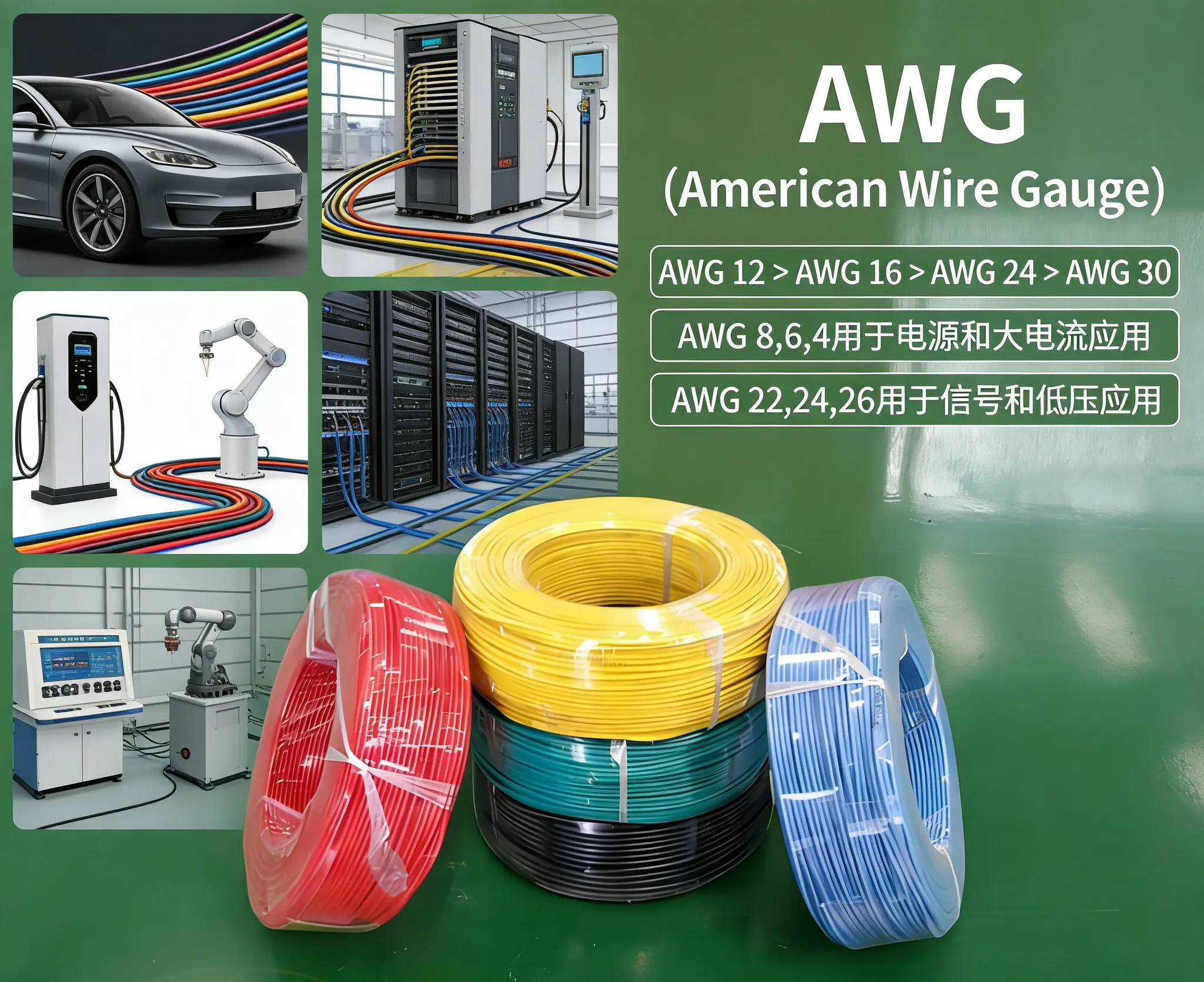

In various scenarios such as automotive wiring harnesses, industrial equipment, charging piles, server cabling, and high-precision signal transmission for robots and medical instruments, wire gauge (AWG) is the first principle for wire harness reliability. It not only determines the current-carrying capacity but also affects voltage drop, heat generation, signal quality, EMC immunity, flexibility, wire harness routing, and overall lifespan. Equipment with high voltage, high speed, strong vibration, and extreme temperature has even more stringent requirements for AWG.

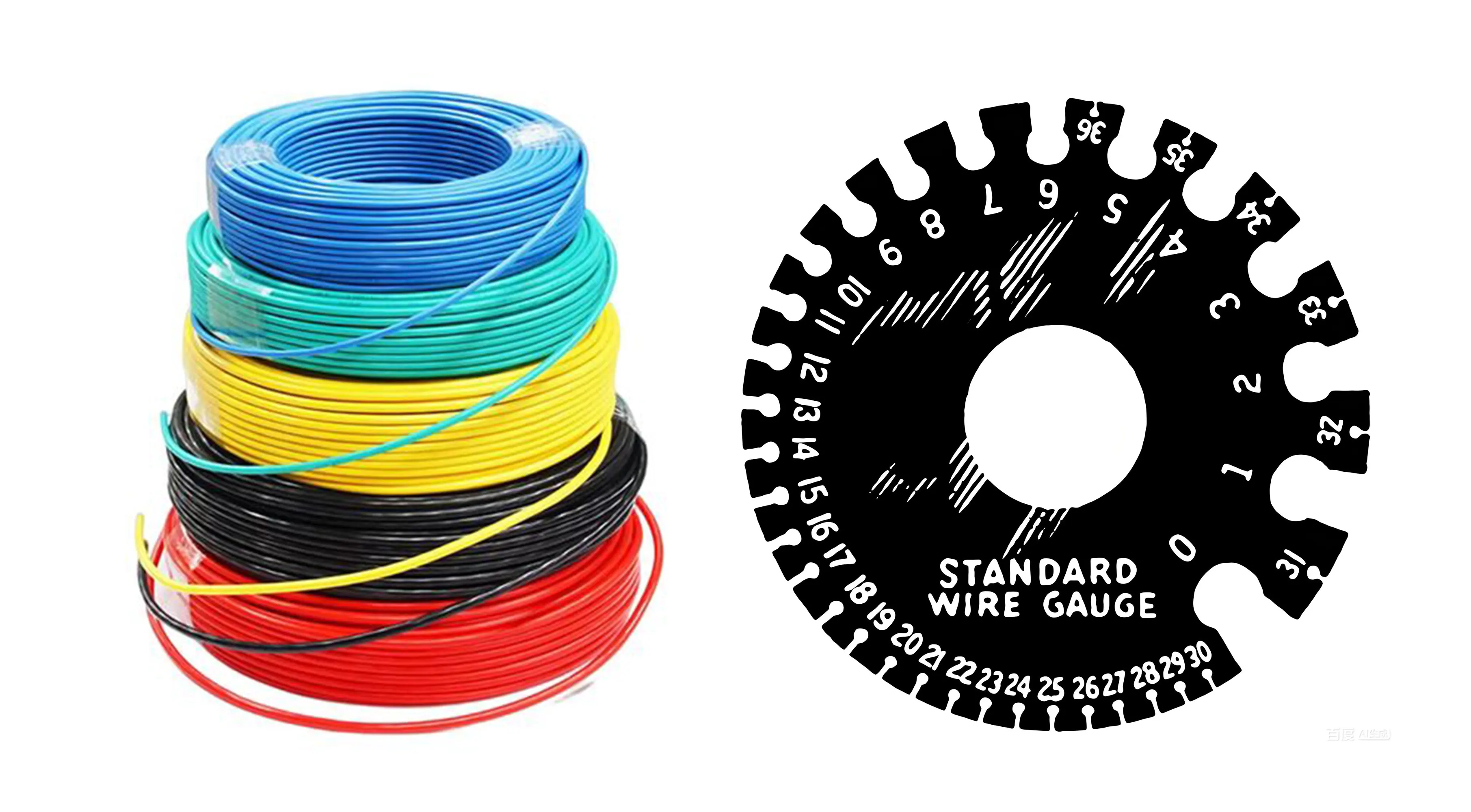

1. What is AWG? Why does the wire harness industry use it?

AWG (American Wire Gauge) is the most commonly used wire gauge standard in North America. The smaller the number, the larger the wire gauge. For example:

- AWG 12 > AWG 16 > AWG 24 > AWG 30

- AWG 8, 6, 4 are used for power and high current applications.

- AWG 22, 24, 26 are used for signal and low-voltage applications.

Its advantages include:

- Highly compatible with global supply chains (used by TE, Molex, and Delphi)

- High manufacturing consistency, facilitating automated crimping

- Standardised parameters for tin-plated copper stranded wire

- Mature applications in automotive wiring harnesses and industrial equipment

2. AWG to mm² Conversion Table

The following is a conversion table for the most commonly used wire harness AWG specifications:

| AWG | Cross-sectional area mm² | Diameter (mm) | Maximum current (safety reference) |

| 30 AWG | 0.05 mm² | 0.25 mm | ~0.15–0.3 A |

| 28 AWG | 0.08 mm² | 0.32 mm | ~0.5–1 A |

| 26 AWG | 0.13 mm² | 0.40 mm | ~1–2 A |

| 24 AWG | 0.20 mm² | 0.51 mm | ~2–3 A |

| 22 AWG | 0.33 mm² | 0.64 mm | ~3–5 A |

| 20 AWG | 0.52 mm² | 0.81 mm | ~5–7 A |

| 18 AWG | 0.82 mm² | 1.02 mm | ~7–10 A |

| 16 AWG | 1.31 mm² | 1.29 mm | ~10–13 A |

| 14 AWG | 2.08 mm² | 1.63 mm | ~15–20 A |

| 12 AWG | 3.31 mm² | 2.05 mm | ~20–30 A |

| 10 AWG | 5.26 mm² | 2.59 mm | ~30–55 A |

| 8 AWG | 8.37 mm² | 3.26 mm | ~55–75 A |

| 6 AWG | 13.3 mm² | 4.11 mm | ~75–100 A |

| 4 AWG | 21.2 mm² | 5.19 mm | ~100–150 A |

Note: Current carrying capacity varies with temperature, insulation material, and laying method; derating must be considered when selecting a system for an engineering project.

3. Commonly Used AWG Recommendation Table for Wire Harnesses

Different types of wire harnesses have different requirements for current, flexibility, shielding, and mechanical strength.

1. Signal harness (Sensor / Communication)

Features: Low current, low noise, often requires shielding

| Application | Commonly used AWG |

| USB, HDMI, ribbon cable | AWG 28 / 30 |

| RS485 / CAN / UART | AWG 22 / 24 / 26 |

| sensor | AWG 24 / 26 |

| LVDS / Camera MIPI | AWG 28 / 30 / 32 |

2. Automotive wiring harness (12V/48V)

The automotive industry has a mature and standardised selection process:

| System | Recommended AWG |

| ECU signal lines | AWG 22 / 24 |

| Low voltage for car doors/lights | AWG 18/20 |

| Fan/pump loads | AWG 14 / 16 |

| Start-up wire (high current) | AWG 4 / 6 / 8 |

| 48V power harness | AWG 6 / AWG 4 / AWG 2 |

3. High-voltage wiring harnesses (robotics / industrial equipment/power systems)

| Voltage level | Recommended AWG | Illustrate |

| 100~300V DC | AWG 18 / 16 / 14 | Industrial power supplies and servo drives |

| 300~600V | AWG 14 / 12 / 10 | High power supply |

| Over 600V | AWG 8 / 6 / 4 | Power system, energy storage battery |

4. Selection Table for AWG Units with Different Currents

The following are commonly used values for engineers, evaluated based on UL general standards, resistance, voltage drop, and temperature rise:

| AWG | Maximum current (A) Safe current carrying capacity | Application |

| 30 | 0.8 A | Weak signal |

| 28 | 1.4 A | Data cable, ribbon cable |

| 26 | 2.2 A | LED, small current |

| 24 | 3.5 A | Control line |

| 22 | 5.0 A | Car signal line |

| 20 | 7.0 A | Low power supply |

| 18 | 10 A | Medium power load |

| 16 | 13~18 A | Motor, power line |

| 14 | 20~25 A | Industrial power supply |

| 12 | 25~30 A | High current wiring harness |

| 10 | 35~40 A | Power output |

| 8 | 55 A | High power DC |

| 6 | 75 A | Electric vehicle power supply |

| 4 | 95 A | High-pressure system |

| 2 | 130 A | High-power inverter |

| 0 | 150~200 A | Starting current |

5. How to select an AWG based on current, voltage, and distance?

When selecting a specific model, the following should be considered:

1. Current (most critical)

The current carrying capacity must be ≥ 1.25 × actual maximum current (with safety redundancy).

2. Voltage Rating

Higher voltages require thicker insulation, not necessarily larger AWG, but manufacturers often use larger wire gauges for safety margin.

3. Voltage Drop

Resistance must be considered for long-distance power lines.

Voltage Drop = Current × Resistance × 2 (loop)

For example, A 24V control system exceeding 10 meters may need to be upgraded from AWG 20 to AWG 18.

4. Operating Temperature

High-temperature environments (engine compartment, near industrial furnaces) require larger wire diameters + high-temperature insulation (XLPE / Teflon).

5. Mechanical Motion

Drag chains, robots → Softer cores (such as 96-strand copper wire) are more resistant to bending than AWG.

6. Common AWG Selection Mistakes by Engineers

- Focusing only on the current, ignoring the voltage drop (the most common mistake for long-distance applications)

- Believing that a larger wire diameter is always better (can lead to crimping failure)

- Ignoring insulation material (PVC and XLPE have significant differences in current-carrying capacity)

- Using excessively large wire harness diameters makes wiring in the equipment impossible

- Forgetting to consider the simultaneous current-carrying temperature rise in current calculations

7. FAQ

Q1: Does a higher AWG number mean thicker yarn?

No, a lower AWG number means thicker yarn (AWG 10 is much thicker than AWG 20).

Q2: Can AWG be completely equal to mm²?

No, it can generally only be considered "approximately equivalent".

Q3: What AWG wire size is commonly used in automotive wiring harnesses?

Signal wire: 22–24 mm

Power wire: 16–18 mm

High power wire: 4–8 mm

Q4: Do high-voltage wiring harnesses always need to be large AWG?

The main determining factor is the insulation material and thickness, not the area; however, for safety reasons, larger AWGs are often used.

8. Summary: How to quickly select AWG for your wire harness?

You can follow these steps:

- Determine the maximum current (core parameter)

- Check AWG – Current Meter → Preferred wire gauge

- Calculate the voltage drop based on the wiring distance

- Calibrate based on environmental conditions (temperature, bending, oil resistance, etc.).

- Adjust according to wire harness processing (crimp terminal compatibility)

- Finally confirm AWG