By quanyu lee

2025-11-13 08:38:17

Why did my wiring harness burn out? Several common causes and solutions.

In wire harness systems, burnout is one of the most troublesome problems. Whether in automobiles, industrial equipment, or communication devices, once a wire harness burns, melts, or smokes, it not only means a potential system outage but also poses a safety risk. Many users believe that "poor quality" is the cause of wire harness burnout, but in reality, wire harness damage is often the result of a combination of factors.

This article will analyze the common causes of wire harness burnout in depth and provide actionable solutions to help you avoid similar problems from the outset.

I. Common Causes of Wiring Harness Burnout

1. Current overload: The load exceeds the design range.

Each wire in the harness has a corresponding rated current. Suppose the user applies too much power to the system (such as replacing a high-power light bulb or adding additional equipment). In that case, the current exceeds the wire's carrying capacity, causing the conductor temperature to rise and eventually leading to the melting of the insulation layer.

Solution:

- Check the current rating and wire gauge compatibility of each circuit.

- Select high-temperature, high-voltage wire harnesses certified by UL or ISO;

- Add fuses or circuit breaker protection devices to critical circuits.

2. Poor contact at the joint: a hidden source of high temperature.

Burnout often starts at the connection points. Poor contact, oxidation, looseness, or poor terminal crimping can all create high-resistance areas, causing localized heating when current flows through, leading to melting or burning.

Solution:

- Use qualified terminals and professional crimping tools;

- Avoid self-soldering or temporary splicing;

- Regularly check wire harness connectors for discoloration, overheating, or unusual odors.

3. Insulation materials are aging or not resistant to environmental conditions.

The insulation layer of the wire harness not only prevents short circuits but also resists humidity, temperature, and chemical corrosion. If exposed to high temperatures, oil, or ultraviolet radiation for a long time, PVC or PE materials will gradually age, harden, or even crack, leading to arc discharge or short circuit and burnout.

Solution:

- Select materials appropriate for the operating environment (e.g., use XLPE, PTFE, or silicone wire).

- Install protective corrugated pipes or insulating sleeves in high-temperature or vibration areas.

- Keep the equipment clean and prevent oil stains from corroding the insulation layer.

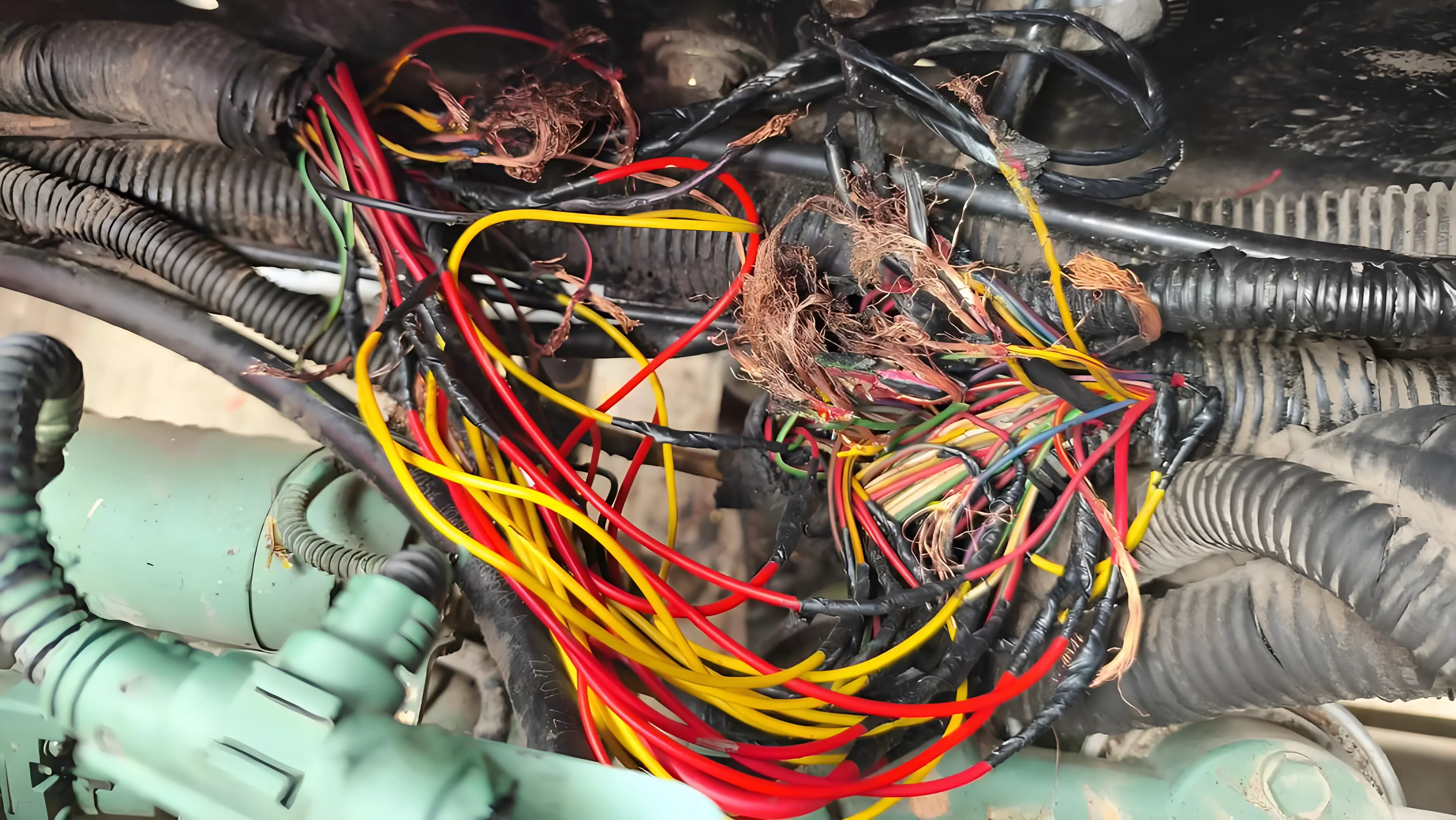

4. Improper Wiring Layout: Mechanical Stress and Heat Accumulation

In many devices, wiring harnesses are excessively bent, stretched, or placed close to heat-generating components (such as engines and transformers). This mechanical stress causes the conductors to be under constant tension, gradually breaking the internal copper wires and creating localized high-resistance points, leading to overheating and burnout.

Solution:

- Follow wiring harness standards (such as IPC/WHMA-A-620).

- Allow sufficient bending radius and avoid sharp angle bends.

- Avoid direct contact between the wiring harness and heat sink, exhaust pipe, or power module.

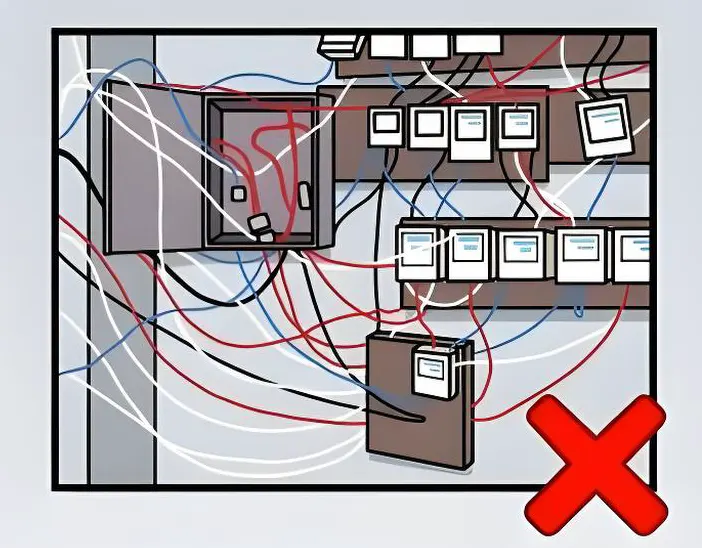

5. Short circuit and ground faults

Short circuits are the "ultimate killer" of wiring harnesses. When the positive or negative terminals or signal lines accidentally come into contact with the metal casing, the current surges instantly, causing intense heat and carbonization of the insulation layer.

Solutions:

- Use high-insulation, abrasion-resistant sheaths.

- Design a reliable grounding system.

- Add an overcurrent protection module.

II. How to prevent wire harness burnout

- Design Phase Control: Ensure wire diameter, current, and environmental compatibility;

- Strict Material Selection: Prioritize materials with UL, CE, and RoHS certifications;

- Qualified Manufacturing Processes: Professional crimping, testing, and insulation inspection;

- Installation Standards: Avoid stress, avoid heat sources, and maintain cleanliness.

- Regular Maintenance: Monitor joint temperature rise and insulation resistance.

If your project requires custom-designed burn-resistant, high-temperature-resistant, or waterproof wiring harnesses, you can consult professional manufacturers such as WIRE HARNESS ASSEMBLY, Specializing in custom wiring harnesses for automotive, medical, and communication equipment, providing enterprises with integrated services from design and material selection to testing.

Ⅲ. FAQ

Q1: Can a burned-out wire harness be repaired?

It is generally not recommended to repair it yourself. Even if it is re-wrapped or soldered, there may still be damage to the internal copper wires or insulation failure. It is recommended to replace the entire wire harness.

Q2: Why do automotive wiring harnesses burn out easily?

Automotive systems operate under low voltage and high current, and in complex environments (high temperature, vibration, humidity). Any loose connection or improper installation of additional electrical equipment can easily cause localized overheating.

Q3: How to tell if a wiring harness is about to burn out?

If you notice an unusual odor, softening, darkening of color, or a sticky insulation layer, it indicates excessive localized temperature rise. Immediately disconnect the power and inspect the harness.

Q4: How to choose a safer wiring harness?

Choose wiring harness products that comply with international standards such as ISO 6722 and UL 758. Check their rated temperature and conductor specifications, and ensure the supplier provides a complete test report.

Ⅳ. Summarize

Wiring harness burnout is not accidental, but rather a result of problems across multiple stages, including design, installation, environment, and maintenance. To fundamentally prevent burnout, it is essential to: select materials scientifically, ensure standardized wiring, conduct regular inspections, and opt for professional customization.

In critical systems, prevention is worse than a cure. By partnering with experienced manufacturers like WIRE HARNESS ASSEMBLY, you can obtain more reliable and secure wiring harness solutions, eliminating the risk of burnout at its source.