By quanyu lee

2025-08-18 02:21:18

Custom Wire Harness Assembly Manufacturing Services | Kaweei

A professional wire harness and cable assembly manufacturer in China, providing customized wire harnesses, complex wire harness assemblies, and turnkey electronic assemblies, serving the medical, aviation, industrial, new energy, and robotics industries.

What is a Wiring Harness Assembly?

A wiring harness is an assembly that bundles multiple wires or cables together, installed within a larger device to provide power or data connectivity. Every wiring harness project varies in length, quantity, complexity, and application.

The difference between wire harnesses and cable assemblies

Wire harnesses: Multiple wires are bundled together to maintain visibility, suitable for general use and commonly found in cars and aircraft.

Cable assemblies: Cable assemblies have an additional outer layer to protect against moisture, friction, and heat, suitable for use in harsh environments.

Kaweei offers custom manufacturing services for both wire harnesses and cable assemblies.

Why choose us?

We have been engaged in the manufacturing of wire harnesses and cable assemblies for decades, and are committed to providing professional connectivity solutions for industries such as industrial equipment, communications, medical, automotive, robotics, and new energy.

Highlights:

- Specializing in complex custom wiring harnesses and turnkey electronic assembly

- Equipped with automation and core technical personnel to ensure consistent quality and efficient production

- A comprehensive supply chain and flexible production layout

- Supporting rapid NPI prototyping and small to medium-volume orders (free small-volume prototyping available)

- Continuously introducing new technologies to meet diverse needs

- ISO 9001:2015 certified and compliant with IPC-WHMA-A-620 standards

Manufacturing capacity

We can produce wire harnesses of any length, quantity, and complexity, accommodating a variety of specialty wires, including high-temperature and marine-grade cables.

Processes include:

- Automated cutting, stripping, and termination;

- Braiding and sleeving;

- Ultrasonic welding and potting;

- ROHS-compliant dip tinning;

- Heat shrink and wire marking;

- In-line hot stamping and label wrapping;

- Pull testing, continuity testing, and functional testing.

New product production process

Bill of Materials (BOM): Engineers review customer requirements and adjust cable lengths and breakouts.

Cut List: Specify wire type, gauge, color, length, and stripping dimensions.

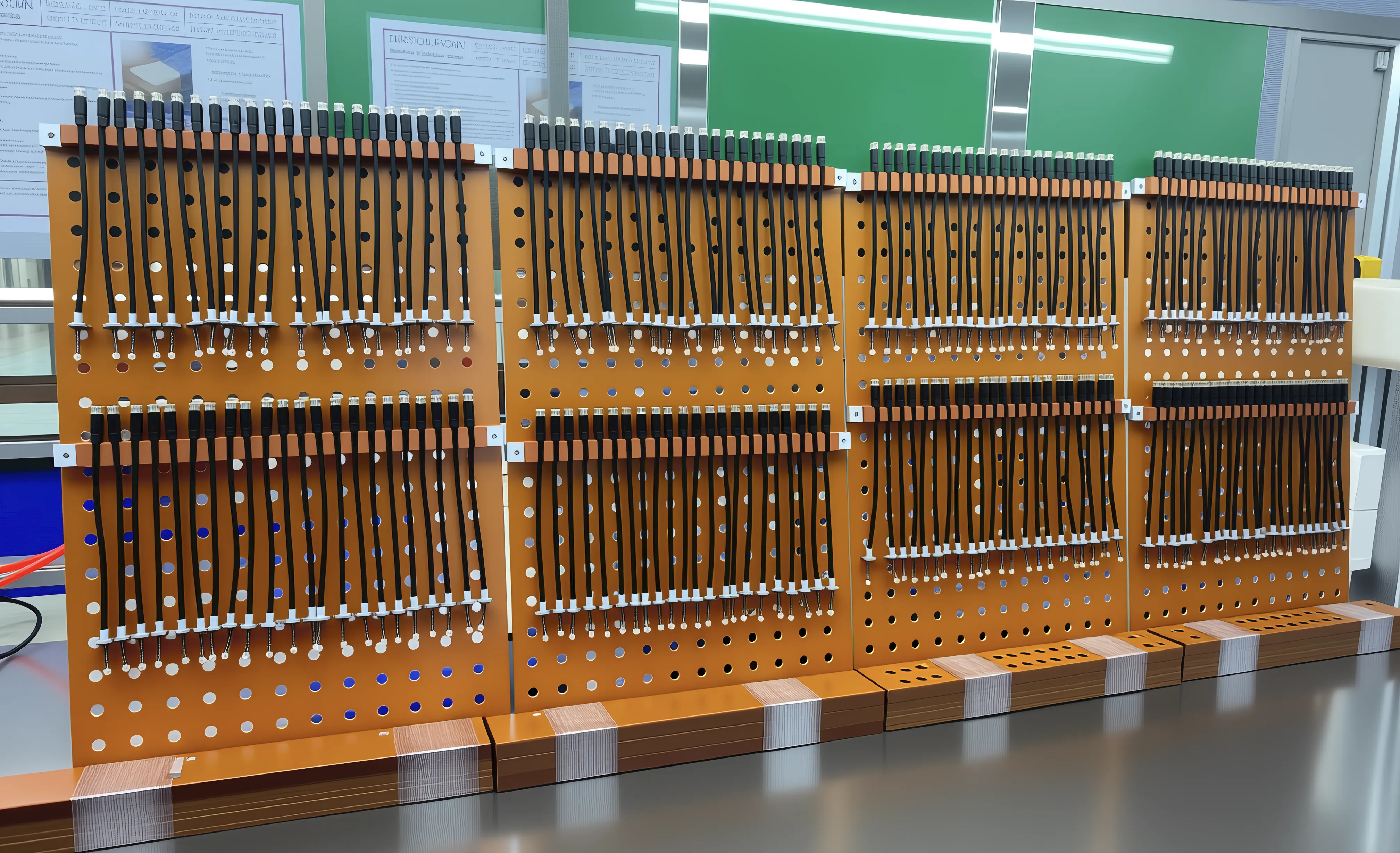

NPI Prototyping: Build a prototype harness on a tooling board and submit to the customer for approval.

Modification and Testing: Adjustments are made and continuity testing is performed.

Mass Production: After sample approval, production begins.

Testing and Quality Control

Cable testing: Detect open circuit, short circuit, wrong wiring, measure resistance and isolation resistance

Automatic pull test: Ensures the crimp is secure and will not damage the wire or fall off.

Wire harness application industry

Our wire harnesses and cable assemblies are widely used in various industries and offer the advantages of durability and stable performance:

Medical Equipment: Diagnostic Instruments, Monitoring Systems, Bed Controls

Aerospace: Avionics Systems, Small Engines, Lighting Systems

Engineering Machinery: Trailer Lighting and Braking Systems

HVAC and Industrial Controls: Air Conditioning, Fresh Air Systems, Commercial HVAC Equipment

Industrial Components: Vending Machines, Gaming Consoles, Stadium Lighting Equipment

Agricultural Equipment: Tractors, Harvesters, Gardening Machinery, Livestock Breeding Equipment

New Energy and Robotics: Power Battery Systems, Automation Equipment, Robot Controls

Frequently Asked Questions (FAQ)

Q1: What is the difference between a wire harness and a cable assembly?

A1: A wire harness bundles multiple wires together for easy installation; a cable assembly has an outer protective layer and is more suitable for harsh environments.

Q2: Do you support small-batch customization?

A2: Yes, we support small-batch production and provide free proofing services.

Q3: What are your quality standards?

A3: We strictly adhere to ISO 9001:2015 and IPC-WHMA-A-620 standards for production and testing.

Q4: What industries do you primarily serve?

A4: Medical, aerospace, industrial equipment, communications, new energy, agriculture, and robotics.

Q5: Do you provide a full-process service?

A5: Yes, we offer complete turnkey solutions from design, proofing, testing, to mass production.

Whether you need a quick, low-volume prototype or a large, complex production run, we can be your trusted partner. If you need a custom wire harness, please contact us!