By quanyu lee

2025-12-20 09:46:09

FFC Guide: Flexible Flat Cable Structure, Spacing, and Selection Tips

In the consumer electronics, industrial control, medical equipment, and automotive electronics sectors, flexible flat cables (FFCs) have become a significant alternative to traditional round cable assemblies due to their thin profile, high density, and high reliability.

However, many engineers still encounter difficulties when selecting these cables, particularly regarding conductor pitch, the difference between FFC and FPC, flex life, and suitability for industrial environments.

This article provides a systematic analysis of FFCs, covering five key aspects: structural principles, key parameters, application scenarios, selection criteria, and common misconceptions. It will help you avoid errors and hidden risks right from the design phase.

I. What is the FFC?

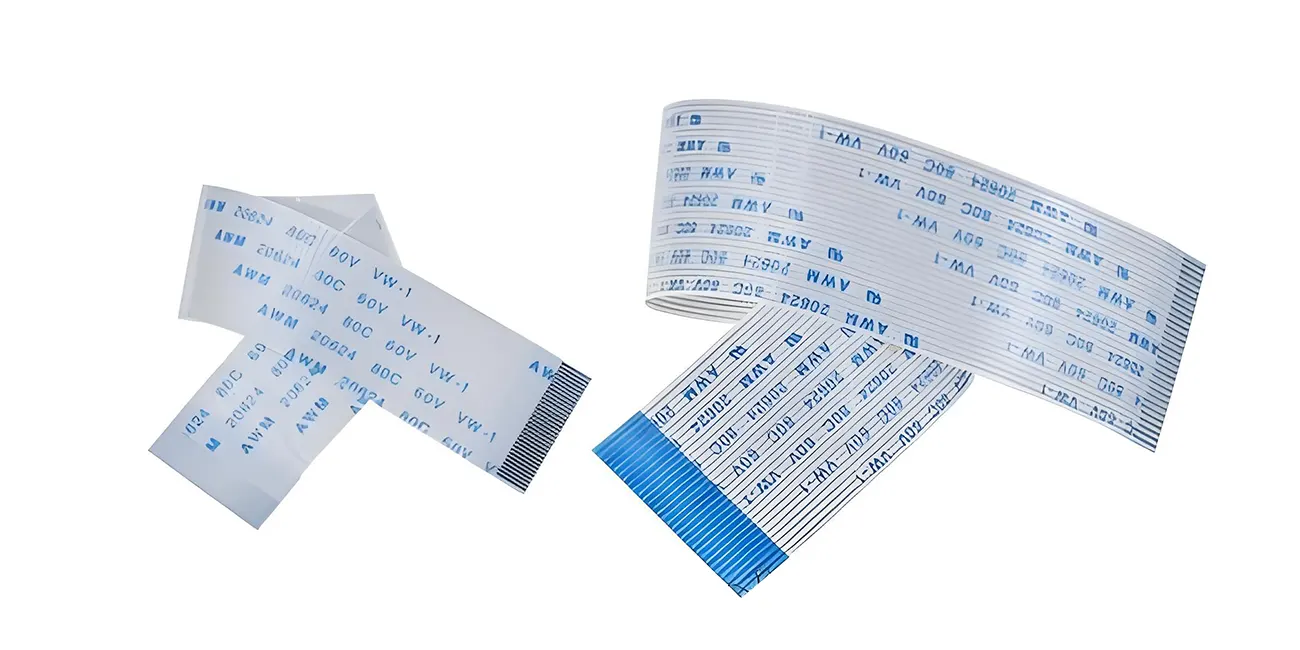

The FFC (Flexible Flat Cable) is not simply a "flexible flat cable," but rather a flexible cable composed of several parallel flat conductors, laminated together with an insulating film.

Compared to traditional round wires, it has the following key characteristics:

- The conductors are arranged with great uniformity, which ensures stable impedance.

- Its extremely thin design is suitable for confined spaces.

- The high consistency between batches facilitates automated assembly.

From an engineering perspective, FFC is not simply a "simplified cable," but rather a standardized interconnection solution designed for high-density interfaces.

II. Analysis of the fundamental structure of FFC

A complete flexible flat cable (FFC) typically consists of the following components:

1. Conductor

- Material: Electrolytic copper or tinned copper

- Shape: Flat copper sheet

- Common thicknesses: 0.035 mm / 0.05 mm

The thickness of the conductor directly affects its current-carrying capacity and lifespan under bending; a greater thickness does not always equate to better performance.

2. Insulation layer

- Common materials: PET, PI (high-temperature resistant type)

- Function: Electrical insulation + mechanical protection

PI material offers advantages in high-temperature applications or those requiring high reliability.

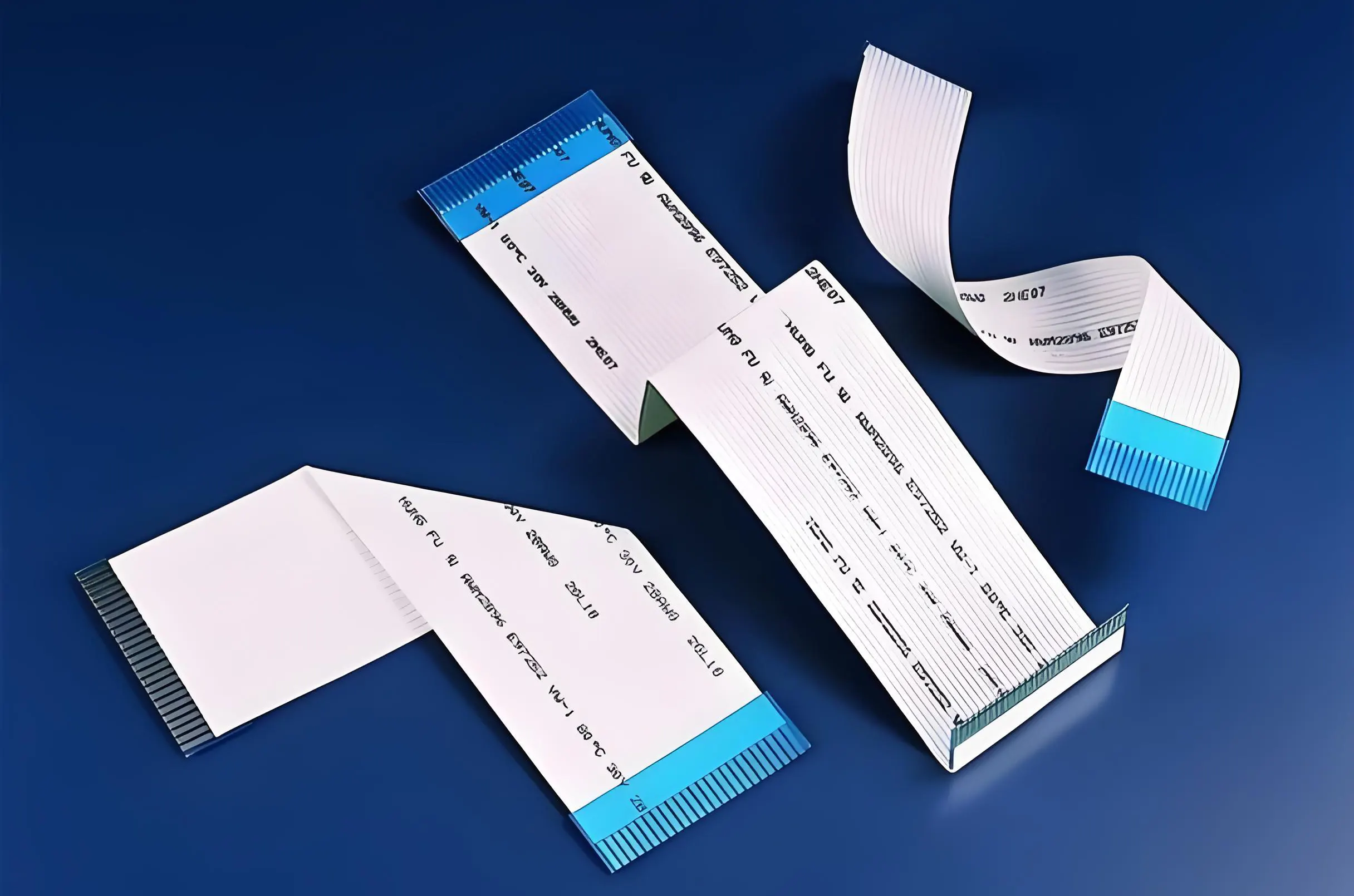

3. Presentation

This is one of the most important parameters for flexible flat cables (FFC). Common specifications include:

- 0.3mm

- 0.5mm

- 1.0mm

- 1.25mm

The pitch of the sound determines:

- The types of connectors that can be used

- The signal density per unit width

- The difficulty of manufacturing and assembly

III. Main technical parameters of the FFC

1. Number of pins (number of conductors)

Customisation is possible for connectors ranging from 4 pins to over 80 pins. The higher the number of pins, the greater the requirements in terms of connector design and assembly precision.

2. Electrical performance

- Rated voltage: typically 30 V / 60 V

- Rated current: typically ≤ 1 A (depending on the pitch and thickness of the conductors)

FFC cables are more suitable for transmitting signals or low-current power, rather than for high-power circuits.

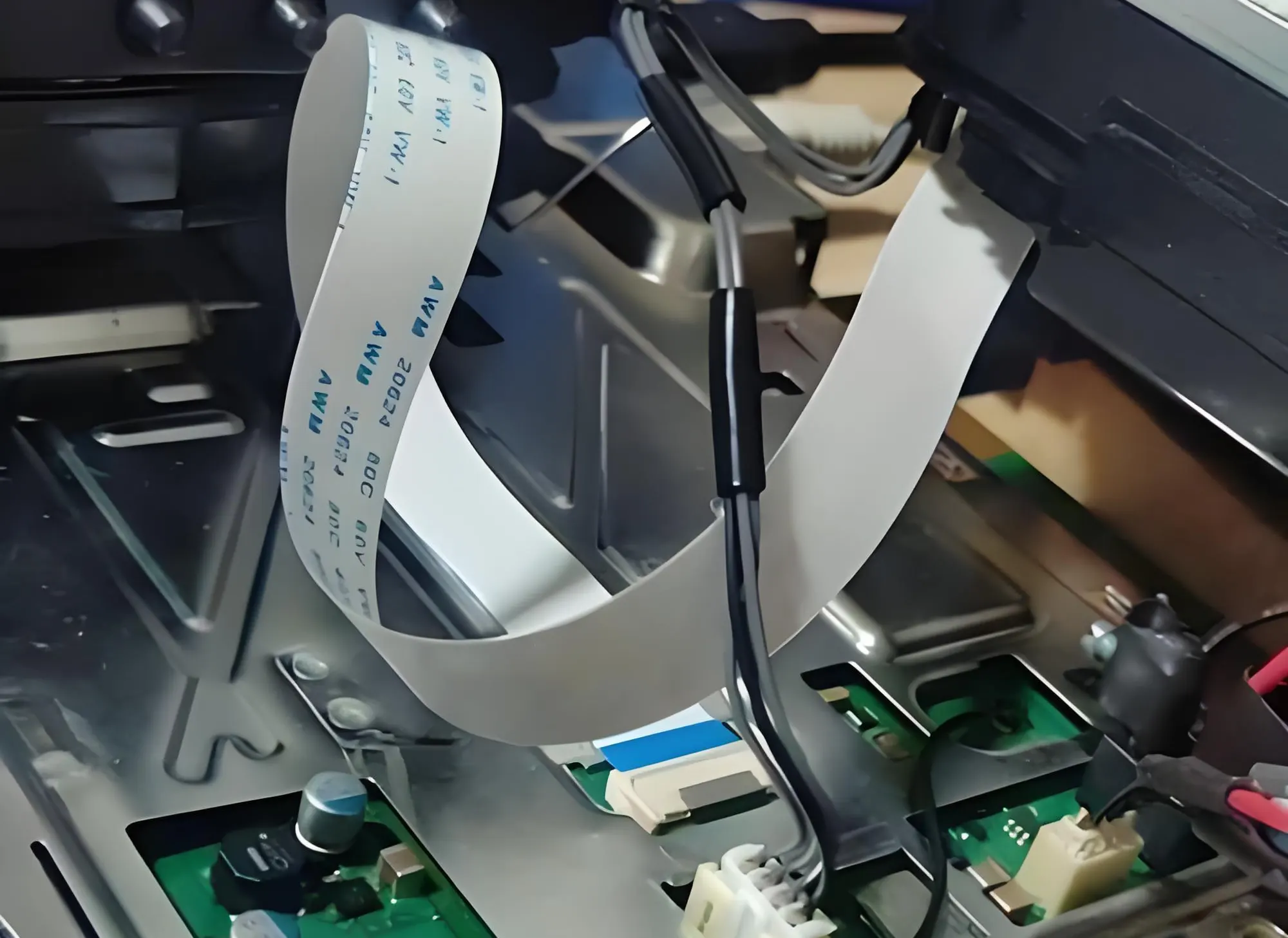

3. Fold life

- Static applications: tens of thousands of cycles

- Dynamic bending applications require specific structural design or materials.

This is the main cause of many project failures: a standard flexible flat cable (FFC) is not equivalent to a cable designed for cable carriers.

IV. Differences between FFC and FPC

| Comparison dimensions | FFC | FPC |

| Structure | Compression of parallel conductors | Engraved copper sheet |

| Cost | Weak | High |

| Customization flexibility | Medium | High |

| Appropriate scenarios | Interface standard | Complex and irregularly shaped |

The conclusion is simple:

- For standardization and cost optimization → choose FFC

- For irregular routing and advanced integration → choose FPC

V. Typical application scenarios for FFC cables

FFC technology is not only found "inside electronic products," but has already penetrated numerous industrial sectors:

- Display modules (LCD/OLED)

- Printers, scanners

- Industrial control panels

- Medical monitoring equipment

- Automotive dashboards and center consoles

In these scenarios, the advantage of FFC lies in: transmitting the most stable signal while using the minimum amount of space.

VI. The engineer's logic for selecting flexible flat cables (FFC)

In practical projects, it is recommended to perform the checks in the following order:

- Confirm the interface pitch (determined by the motherboard).

- Determine the number of pins and the length tolerance.

- Evaluate the operating environment (temperature/bending/vibration).

- Match the connector model (straight/reverse/same direction/opposite direction).

- Perform customized reinforcement design if necessary.

Involving a factory specializing in cable harnesses at this stage can often reduce subsequent problems by 80%.

VII. Customizing FFC cables or using standard parts: how to choose?

- Research and development in small series / Standard interface → Standard FFC cable

- Mass production / Specific lengths / Special environments → Customized FFC cable

Standard flexible flat cables (FFCs) are suitable for small-batch R&D projects and applications requiring standardized interfaces, while custom flexible flat cables are ideal for mass production and applications requiring specific lengths and environmental adaptation. Factories specializing in the customization of cable assemblies and flat cables, particularly those offering cable harness assembly services, typically provide customization options for pitch, length, and pin count, as well as optimization of materials and temperature resistance, and integrated design services to ensure compatibility with the overall wiring system of the finished product.

VIII. Frequently Asked Questions (FAQ)

Q1: Can FFC cables transmit high-speed signals?

Yes, but care must be taken to control the impedance, ensure regular spacing of the wires, and use high-quality connectors. They are commonly used in display and data transmission interfaces.

Q2: Can FFC cables withstand frequent bending?

Standard FFC cables are not suitable for high-frequency dynamic bending applications; specific designs are required for this type of application.

Q3: Can flexible flat cables (FFC) replace cable harnesses?

It can be used in low-current, short-distance, and high-density applications, but it is not a universal replacement.

IX. Conclusion

The flexible flat cable (FFC) is a component that requires careful consideration from the design phase onward. Although inexpensive to purchase, the cost of modifications due to a poor choice is extremely high. The truly professional approach is to integrate it into the overall system interconnection solution from the earliest stages of product design, rather than treating it as a temporary fix. Furthermore, for those involved in product development, prototype design, or production evaluation, understanding the engineering principles behind FFCs is far more important than simply memorizing a few specifications.