By quanyu lee

2025-10-21 09:20:34

ECU Wiring Harness Guide for Automotive Control Systems

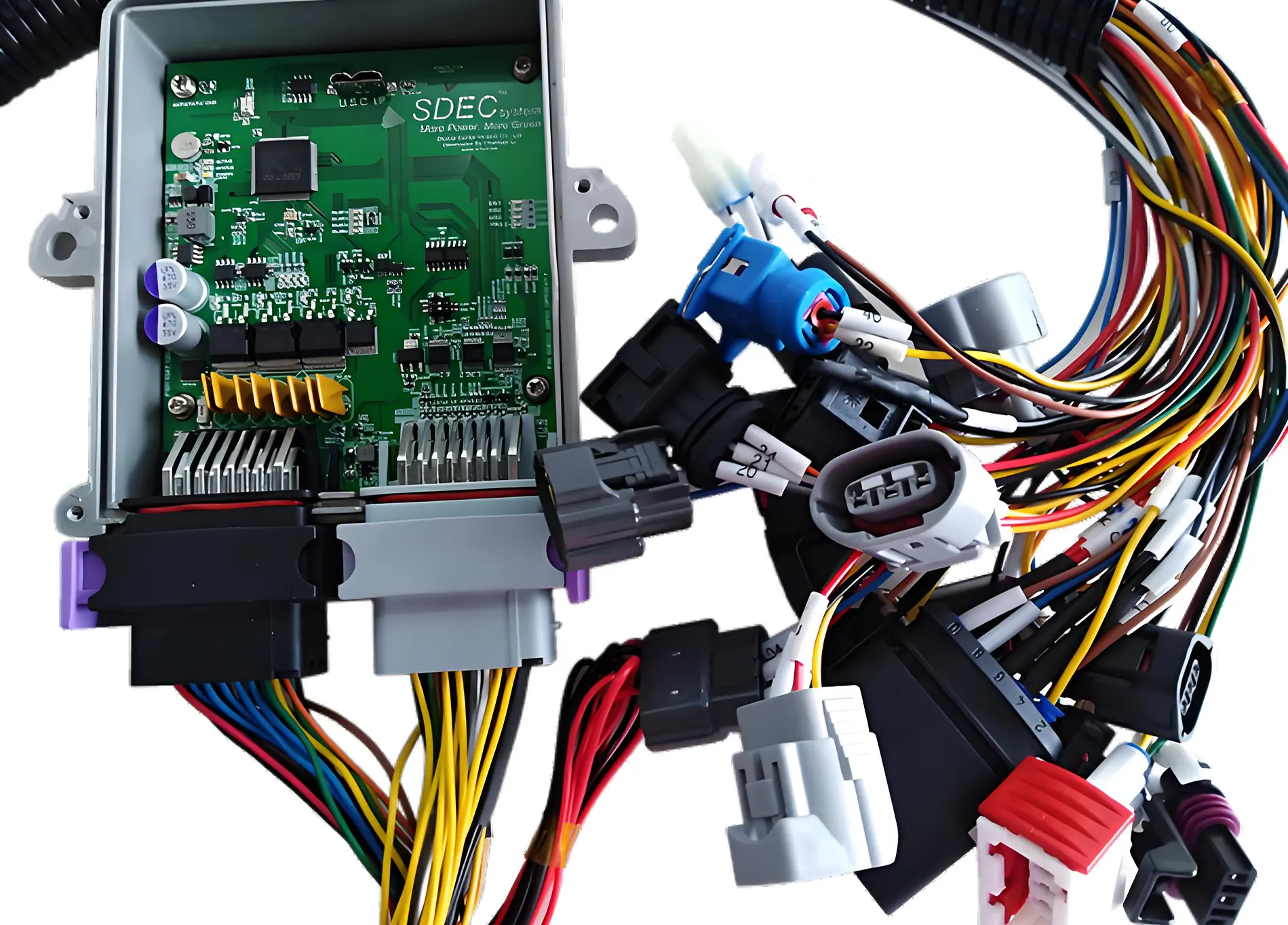

The engine electronic control unit (ECU) is responsible for transmitting signals and control instructions. The ECU is a key component in engine management, acting as a "smart commander" for the engine. It automatically monitors the engine's operation throughout the entire process, eliminating the need for manual control. When you step on the accelerator to accelerate, it calculates the appropriate engine power output while also minimizing fuel consumption and ensuring emissions meet national regulations. However, the ECU alone is not enough; it relies on sensors to collect information about engine speed and temperature, and actuators to adjust fuel injection. The sensors, actuators, and ECU are all connected by the ECU wiring harness, transmitting signals and ensuring their operation.

What is an ECU wiring harness?

ECU wiring harnesses are cable assemblies designed specifically for vehicle electronic control units. They are primarily used to connect modules such as engine control, transmission control, ABS, airbags, and body control, enabling data and power transmission.

Core components include:

- Wires: Mostly high-temperature, interference-resistant automotive-grade copper wire.

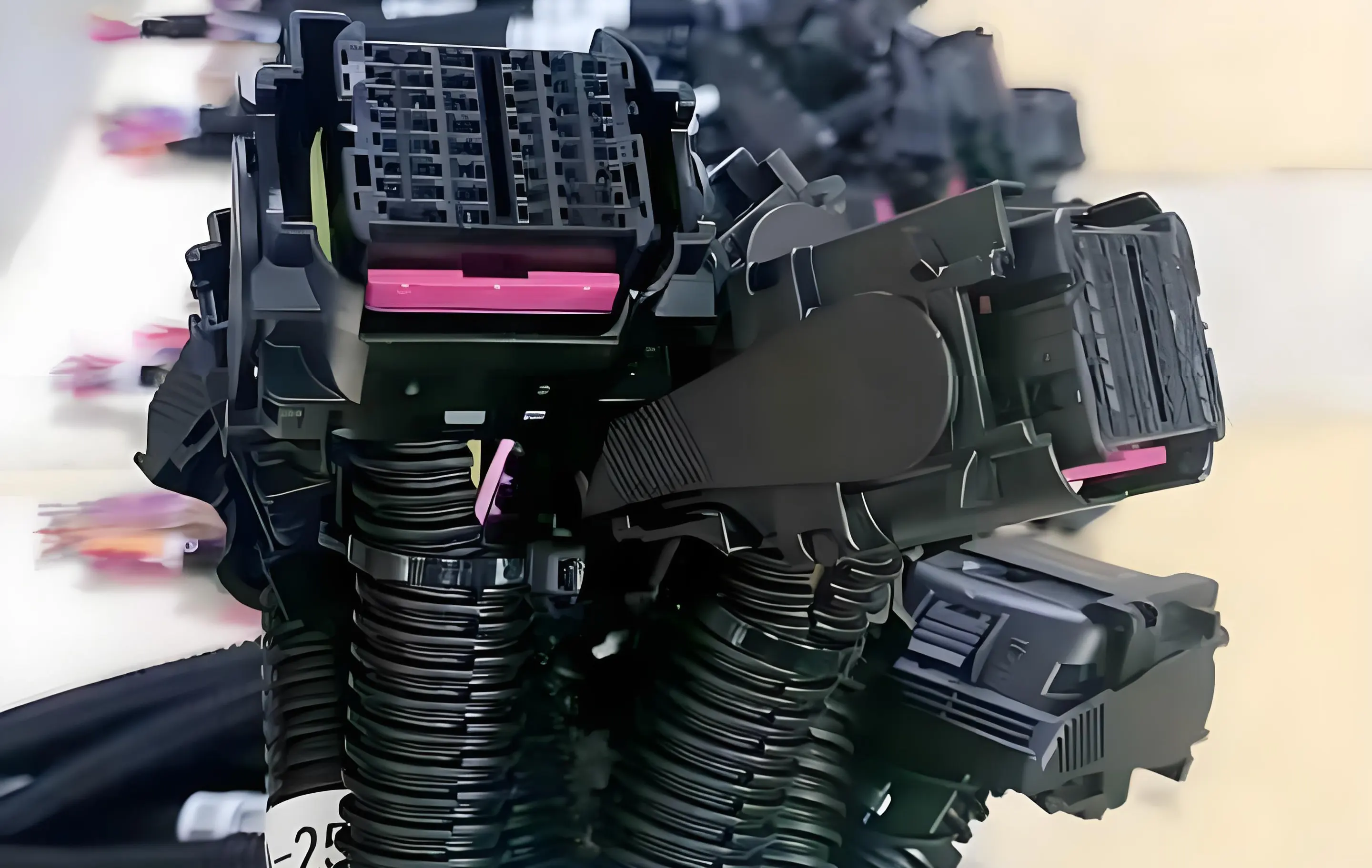

- Connectors: Precisely mate with the ECU plug to ensure stable signal transmission.

- Insulation and sheathing: Protect the wiring harness from heat, oil, and vibration.

- Securing clips and wrapping material: Keep the wiring harness neatly routed and prevent loosening or rubbing.

Technical requirements for ECU wiring harness

ECU wiring harnesses have extremely high technical requirements in design and manufacturing:

| Technical indicators | Require |

| working temperature | -40°C ~ 125°C |

| Anti-interference performance | Must meet ISO 11452, CISPR 25, and other standards |

| signal integrity | The data cable must have a shielding layer to prevent electromagnetic interference |

| Waterproof level | Key parts are required to reach IP67 or above |

| Durability testing | Need to pass vibration, salt spray, thermal cycle, and other tests |

ECU Wiring Harness Types and Applications

The ECU wiring harness used by different vehicle models and control systems varies. Common types include:

- The Engine Control Harness (Engine ECU Harness) is used for fuel injection, ignition control, and exhaust sensor signal acquisition.

- The Transmission Harness (Transmission Harness) transmits shift control signals and hydraulic pressure feedback.

- The Body Control Harness (Body ECU Harness) connects modules such as door locks, lighting, windows, and power seats.

- The ADAS and Intelligent Driving Harness (ADAS ECU Harness) connects high-frequency devices such as cameras, radar, and millimeter-wave sensors.

ECU Wiring Harness Customization and Design Key Points

High-quality ECU wiring harnesses are typically customized based on the vehicle model and function. Key design points include:

- Precisely matching ECU port and pin assignments

- Selecting appropriate wire diameters (separating signal and power lines)

- Optimizing wiring paths to avoid high-temperature and vibration areas

- Incorporating EMI shielding and grounding features

- Modular interfaces for easy assembly and maintenance

ECU Wiring Harness Testing and Quality Control

Before leaving the factory, ECU wiring harnesses undergo rigorous testing:

- Continuity Test

- Insulation Resistance Test

- Voltage Load Test

- Waterproof and Heat Resistance Test

- Pin Insertion and Removal Force Test

These links ensure that each wiring harness remains stable and reliable under extreme working conditions.

FAQ: Frequently asked questions about ECU wiring harness

Q1: What's the difference between ECU wiring harnesses and standard automotive wiring harnesses?

ECU wiring harnesses are primarily used to transmit high-precision electronic control signals, requiring higher levels of anti-interference, shielding, and signal integrity. Standard automotive wiring harnesses, on the other hand, are primarily used for low-frequency applications such as lighting and power supplies.

Q2: Why do ECU wiring harnesses need shielding?

ECU wiring harnesses often connect to weak signal devices such as sensors and control modules. External electromagnetic interference (EMI) can affect data transmission. Shielding effectively reduces interference and ensures signal stability.

Q3: How are ECU wiring harnesses different in new energy vehicles?

ECU wiring harnesses in new energy vehicles typically withstand higher voltages and temperatures. Therefore, they use high-temperature-resistant, low-smoke, halogen-free materials with enhanced insulation performance. They also employ a multi-layer shielding structure to prevent high-voltage interference.

Q4: What is the typical lifespan of an ECU wiring harness?

Under normal use and proper wiring, an ECU wiring harness can provide stable service for 8–10 years or longer. However, prolonged exposure to high temperatures or mechanical stress can shorten its lifespan.

Q5: How do I determine if the ECU wiring harness needs to be replaced?

The following symptoms can indicate this:

- ECU module communication anomalies or errors.

- The engine is having difficulty starting.

- Loose wiring harness connectors or deteriorating insulation.

- Signs of burning or short circuits.

- If any problems are found, they should be promptly inspected and replaced to avoid system failure.

Q6: Can you customize the ECU wiring harness for a specific vehicle model or project?

Of course. WIRE HARNESS ASSEMBLY can provide OEM/ODM custom designs based on the customer's specified ECU pinout, layout, and operating environment requirements, including wire diameter, connector type, and shielding scheme.