By quanyu lee

2025-04-23 03:36:10

What does IP69K mean?

In environments where equipment is exposed to extreme dust, high-pressure cleaning, or harsh weather conditions, protection standards become a critical consideration. Among these, IP69K stands out as the highest protection level against both dust and high-temperature, high-pressure water intrusion.

1. What Is IP69K?

IP69K is an internationally recognized Ingress Protection (IP) rating defined by ISO 20653, originally developed in Germany for the automotive industry.

“IP” stands for Ingress Protection, indicating the level of sealing effectiveness against solids and liquids.

“6” signifies complete dust-tight protection — the highest solid ingress level.

“9” means the equipment can withstand high-pressure water jets.

“K” indicates that the product complies with DIN or ISO automotive standards, especially for dynamic spray cleaning environments.

2. IP69K Applications

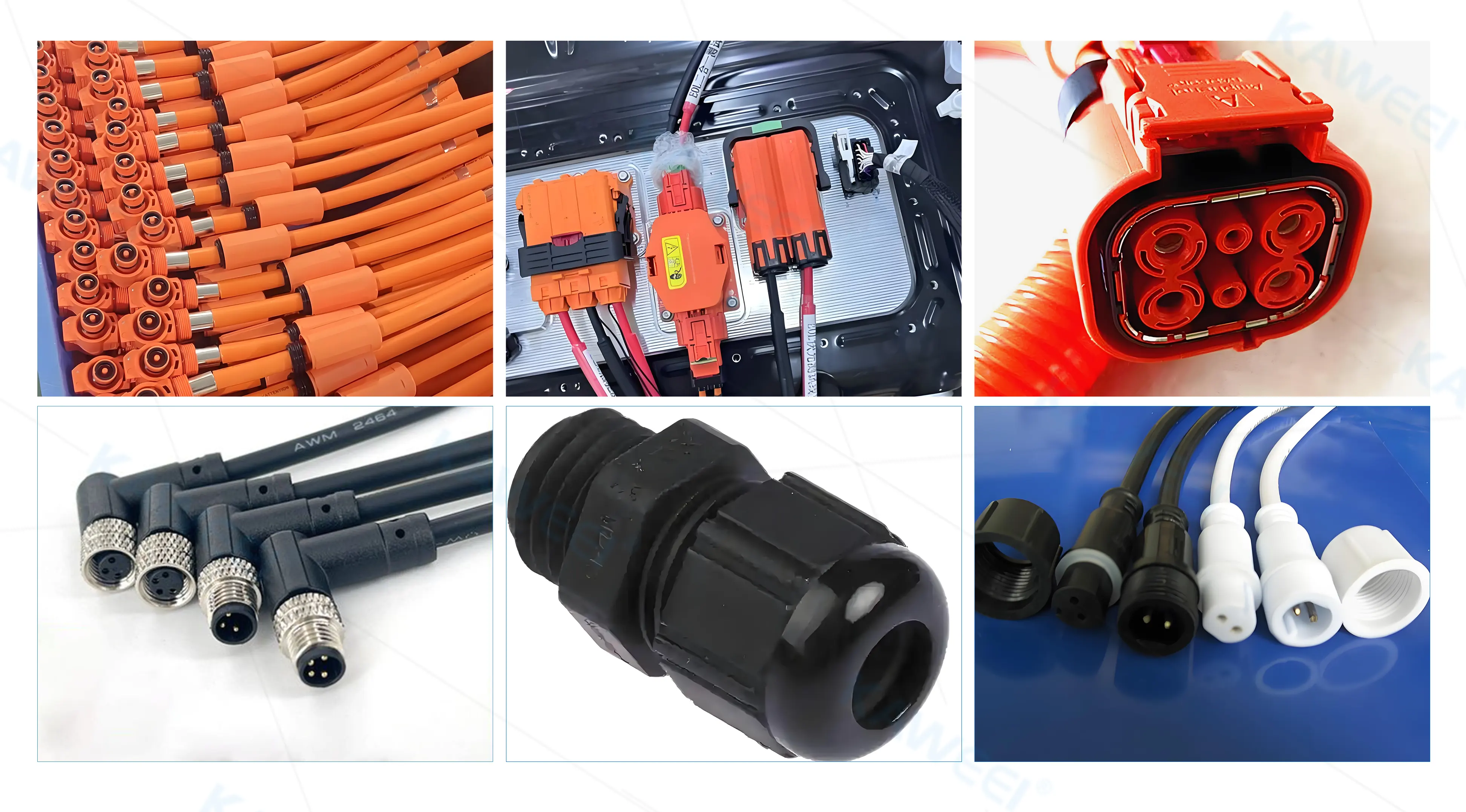

IP69K-rated components are specifically designed for industries requiring extreme cleanliness, contamination control, or environmental protection.

New Energy Vehicles

- High-voltage wiring harness assemblies

- Battery pack housings

- Charging connector interfaces

Industrial Equipment

- Food processing machinery (requiring high-pressure sterilization)

- Medical equipment (requiring sterile environments)

- Outdoor monitoring or communication systems exposed to rain and dust

3. The difference between IP69 and IP69K

| Criteria | IP69 |

IP69K |

| Dustproof Level | Complete protection (IP6X) | Complete protection + vacuum testing (≤2kPa pressure difference) |

| Waterproof Level | High-pressure water jets | 80°C water, 80–100 bar, sprayed at 0°, 30°, 60°, 90°, ≥2 mins |

| Automotive Standard | No | Yes (DIN/ISO Compliant) |

| Dynamic Flush Resistance | Not emphasized | Yes ("K" means tested under dynamic conditions) |

4. Frequently Asked Questions (FAQs)

Q1: What does the “K” in IP69K stand for?

A: The “K” refers to compliance with DIN 40050-9 or ISO 20653, mainly for automotive and industrial uses requiring high-pressure steam cleaning.

Q2: Is IP69K better than IP68?

A: It depends. IP68 focuses on water submersion resistance, while IP69K is about high-pressure and high-temperature spray resistance. They're used for different environments.

Q3: Can IP69K components be used outdoors?

A: Absolutely. IP69K components are ideal for outdoor, dusty, and wet environments, ensuring long-term durability.

Q4: Are all IP69 components also IP69K certified?

A: No. IP69 does not necessarily include dynamic water spray testing, while IP69K does, making it more rigorous.