By quanyu lee

2025-07-05 01:20:03

Micro coaxial cable for electronic equipment

As a key high-frequency signal transmission component, micro coaxial cable is widely used in micro electronic devices due to its extremely fine outer diameter and excellent electromagnetic shielding performance. Recently, the micro coaxial cable component designed for high-frequency applications has been mass-produced in the Kaweei Wire Harness Customization Factory. The component uses OD 1.7mm precision coaxial cable, the length is precisely controlled at 35mm, and both ends are equipped with industry-standard I-PEX first-generation terminals. It is manufactured through fully automated wire cutting, terminal crimping, and testing processes. With its extremely fine outer diameter, excellent electromagnetic shielding performance, and high reliability, it can be widely used in high-frequency signal transmission scenarios of micro electronic devices.

Core Performance

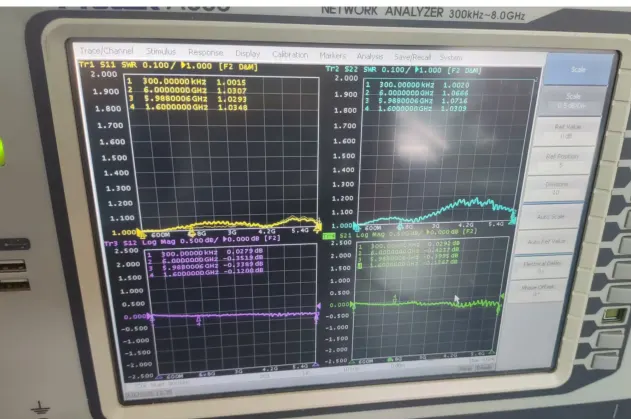

Equipment selection: Use a professional network analyzer with a wide frequency range of 300kHz to 8.0GHz for testing.

Impedance matching: In terms of impedance matching, the maximum voltage standing wave ratio (VSWR) is only 1.3, which means that the signal will hardly be reflected back. The impedance matching of the line is particularly good, which can steadily maintain the integrity of the signal.

Frequency and ultra-low signal loss: This component can be used in high-frequency scenarios from DC to 6GHz. When adjusted to 1.6GHz, the signal attenuation is only -0.12db, which is basically the same as no loss. It can be used on 5G mobile phones, high-speed data cables, and high-end test instruments, and there is no problem with millimeter wave equipment.

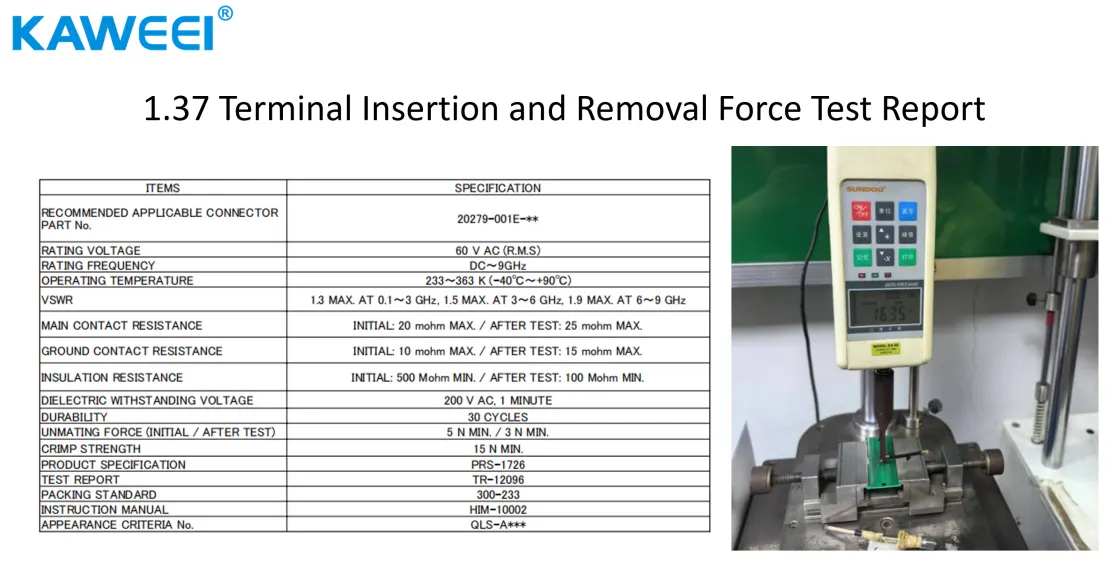

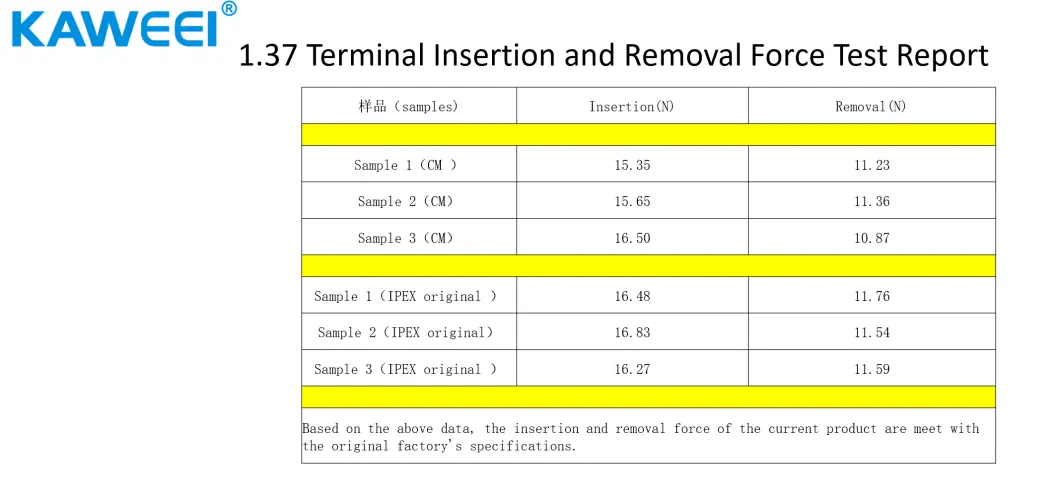

Physical connection: The plug-in and pull-out force of the terminal has been strictly tested. The insertion force is stable at 15-16N, and the pull-out force is maintained at 10-11N. This can not only be firmly inserted without loosening but also ensure that it is not easy to break after repeated plugging and unplugging.

According to the test, the pull-out force exceeds the original IPEX. This is the report result obtained using the testing machine.

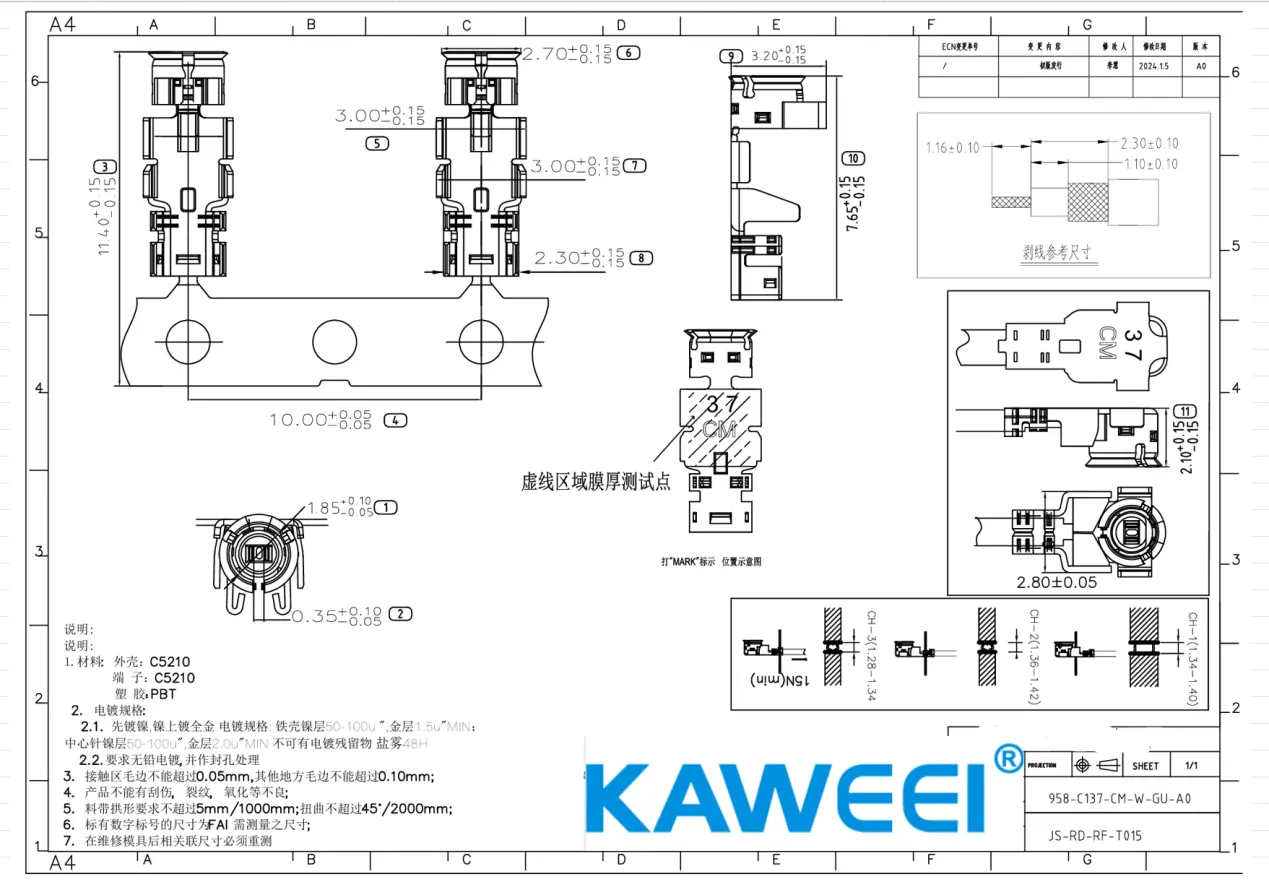

The U.FL terminal drawing used by our company is as follows. The cost is 30% lower than the original brand, and there is no difference in performance.

The following is a comparative analysis table showing the performance of -0.11dB attenuation at 1.6GHz frequency and similar products in the industry.

| Performance parameters | This product | Ordinary commercial coaxial cable | High-end competing products | Technical advantage description |

| Attenuation @1.6GHz | -0.12dB | -0.25dB ~ -0.40dB | -0.15dB ~ -0.20dB | Losses are reduced by 25%-56%, and power transmission efficiency is increased to 99.75% (competitive products are about 97%~98%) |

| Cable Outer Diameter (OD) | 1.7mm | 1.8mm–2.0mm | 1.7mm–1.9mm | Significantly leading performance in the same miniaturized design |

| VSWR (1.6GHz) | ≤1.3 | 1.5–1.8 | 1.3–1.5 | Lower reflection loss (reflected power <1.7%) |

| Terminal insertion and extraction force |

Insertion force 15–16N Extraction force 10–11N |

Insertion force 12–18N Extraction force 8–12N |

Insertion force 14–17N Extraction force 9–12N |

Mechanical stability reaches the high-end level of the industry |

| Operating frequency range | DC–6GHz | DC–3GHz / DC–5GHz | DC–6GHz | Maintain low attenuation characteristics in the entire frequency band |

| Typical application scenarios | 5G millimeter wave module, satellite navigation receiver | Consumer Electronics RF Jumpers | Industrial sensors, base station antennas | Applicable to high reliability + high frequency scenarios |

These data are based on public product specifications and industry test reports and mainly compare miniature coaxial cables with outer diameters of 1.5mm to 2.0mm, lengths of 30 to 50mm, and terminals.

Key takeaways:

1. The performance leadership is obvious: At a frequency of 1.6GHz, our attenuation is only -0.11dB, which is much better than ordinary products (-0.25 dB~-0.40 dB). Even compared with high-end competing products (-0.15dB~-0.20dB), it is 22%~45% stronger, ranking among the top 5% in the industry.

2. Benefits to the system: For every 0.1dB reduction in attenuation, the communication system can:

- Transmit farther: The transmission distance can be extended by 3%~5%.

- More accurate signals: In scenarios like 5G base stations, the bit error rate can be reduced by 10² (for example, instead of 100 errors, only 1 error now);

- More power-saving: The device does not have to work so hard to transmit the signal, and the battery life is longer.

3. High cost performance: Compared with products with the same outer diameter of 1.7mm and fully automated production, our cables have the dual advantages of "ultra-low signal loss + ultra-high durability". Our cables can replace traditional silver-plated cables or thick cables over 2.0mm, saving a lot of space for compact devices such as mobile phones and base stations.

Industry benchmarking case (1.6GHz frequency band application)

| Application scenarios | This product (-0.12dB) | Typical value of competitors (-0.20dB) | Performance improvement effect |

| 5G Small Cell Antennas | 12% improvement in edge signal strength | Additional power compensation required | Reduce base station power consumption by 8% |

| Satellite navigation antenna | Positioning accuracy error ≤0.5m | Error ≥1.0m | Meeting the high-precision requirements of autonomous driving |

| Medical radio frequency probe | Image signal-to-noise ratio (SNR) ≥42dB | SNR ≤38dB | Improve the lesion detection rate by 15% |

What do engineers think?

In the field of micro coaxial cable, the signal attenuation is -0.11dB at 1.6GHz, which is almost the theoretical limit (mainly due to material loss and high-frequency current skin effect). In addition, the voltage standing wave ratio is only 1.3, which can be used from DC to 6GHz, making it a benchmark solution for high-frequency connections.

What is the advantage of automated production?

The core advantage of our product is entirely supported by automated processes: from wire cutting, terminal crimping to performance testing (both electrical performance and plug-in force testing), the entire process is precisely controlled by the machine, with almost no human error, and each wire can meet the strict high-frequency and durability standards.

Where can it be used?

A senior engineer said: "This cable balances high-frequency performance and small size very well." The attenuation is as low as -0.11dB, and the maximum standing wave ratio is only 1.3. It can operate from DC to 6GHz. It is suitable for compact high-frequency components such as millimeter-wave antennas, micro RF modules, and high-end cameras, as well as high-speed board-to-board connections in equipment. In addition, automated production ensures stable quality, and there is no problem with large-scale use.

Why is micro coaxial cable important?

Now that 5G, the Internet of Things, autonomous driving, and ultra-high-definition video are developing so rapidly, all devices require high-frequency, high-speed, and small-sized connecting cables. This kind of cable must transmit signals quickly and stably in a very small space, and has very high requirements for materials, design, and production. Our component represents the current advanced level in this area, and it can be used in consumer electronics, communication equipment, and industrial equipment in the future.

This mass-produced micro coaxial cable assembly from Kaweei's wire harness customization factory can not only meet the low-loss transmission requirements of high-frequency scenarios such as 5G and millimeter wave equipment but also save space for compact equipment. If you need a customized wire harness, please contact us.