By quanyu lee

2025-06-27 07:36:04

RJ45 wiring harness production process detailed explanation

As the core transmission medium of modern network communication, this RJ45 Ethernet data cable has demonstrated irreplaceable technical advantages in the field of data transmission with its excellent material selection, precision process design, and wide applicability. The interface adopts an 8-bit 8-contact (8P8C) standardized structure, and ensures the stability of signal transmission through high-purity oxygen-free copper conductors and multi-layer shielding design. Its modular crystal head crimping process can support the full range of cable standards from Cat5e to Cat8, which can not only meet the stringent requirements of Gigabit Ethernet, but also be compatible with diversified application scenarios such as industrial automation, data centers and smart buildings, providing reliable physical layer protection for key links such as 5G base station backhaul and IoT terminal access.

Core material analysis: Building a hardware foundation for stable transmission

The RJ45 8P8C male connector adopts a standard 8-pin design. The outer mold is red PVC low-pressure injection molding material (pressure < 1.5Mpa, temperature 200°C molding), and the inner mold is PE material with excellent flexibility and weather resistance, which can withstand tens of thousands of plug-in and pull-out cycles; the female connector is black PVC molding material with anti-slip surface treatment; it is matched with CATA6A S/FTP 4*26AWG+Drain+AL+BRAID structure wire (outer diameter 6.2mm), the high-purity oxygen-free copper wire core conductivity is 15% higher than that of ordinary copper wire, the triple shielding system resists high-frequency electromagnetic interference, the outer sheath is low-smoke and halogen-free and complies with RoHS standards, and has a temperature resistance of -20℃~70℃. It is optimized for high-speed data transmission, ensuring stable transmission of 1G/10G Ethernet signals and a bit error rate as low as 10¹².

Production process secrets: triple process to ensure product reliability

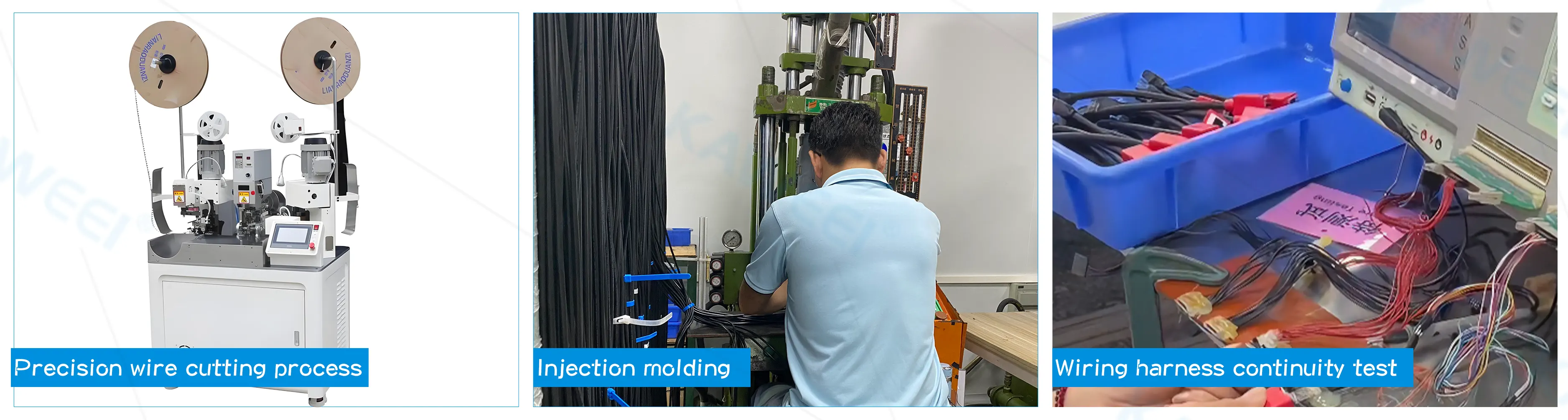

1. Precision wire cutting process

The CNC wire cutting machine can achieve high-precision wire cutting of ±0.5mm to avoid poor connector crimping caused by wire being too long or too short. At the same time, each batch of wire is fully inspected for outer diameter and shielding layer integrity to control the quality of raw materials from the source.

2. Two-step molding inner and outer mold technology

One-step molding inner mold: Utilize high-hardness PE material to wrap the connection between the wire core and the connector, thereby strengthening the mechanical connection between the metal terminal and the wire. The tensile strength is ≥50N, which can effectively cope with the bending of cables in frequent mobile scenarios.

Second-step molding outer mold: The RJ45 male end is low-pressure injection molded with red PVC material, and the female end is injection molded with black PVC material. The seamless combination of the connector and the wire is achieved through the precise positioning of the mold. The bending resistance is >50,000 times.

3. Full inspection and continuity test

Each finished line must pass 100% continuity test, using high-precision tester to detect line sequence, 300V, insulation resistance (>10MΩ) and contact resistance (<50mΩ) to ensure there are no short circuit, open circuit or crosstalk problems, and the electrical performance is fully in line with IEEE 802.3 standards.

Application scenarios: enabling efficient interconnection of communication devices in multiple fields

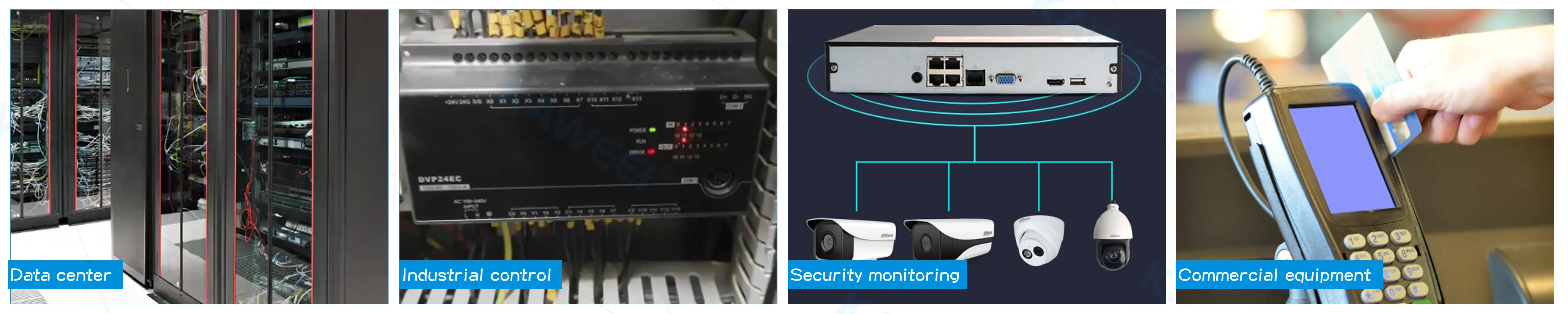

This data cable is designed for Ethernet data transmission and is widely used in:

Data center: high-speed interconnection between servers, switches, and storage devices, supporting 10Gbps transmission rate, reducing latency and packet loss rate;

Industrial control: anti-interference connection of PLC, industrial routers, and other equipment, stable operation in workshop environments with complex electromagnetic environments.

Security monitoring: long-distance transmission of high-definition cameras and NVRs to ensure that video data is not stuck or distorted;

Commercial equipment: network connection of POS machines and smart terminals to improve equipment response speed and data security.

Why choose this RJ45 Ethernet cable?

✅ Material advantages: PE/PVC dual-material outer mold + triple shielded wire, taking into account durability and anti-interference;

✅ Process advantages: Two-time molding technology improves mechanical strength, and full inspection and testing ensure zero defects before leaving the factory.

✅ Scenario adaptation: Red/black dual connector design facilitates device differentiation, and 6.2mm outer diameter is compatible with narrow wiring space;

✅ Environmental compliance: Complies with EU RoHS and REACH certifications, and supports global market access.

With the growing demand for data transmission, an Ethernet data cable with both high performance and high reliability is the key to the stable operation of communication equipment. Through material innovation, process optimization, and strict quality control, KAWEEI provides a one-stop transmission solution for industrial, commercial, data center, and other scenarios. If you need to know more product specifications or customized requirements, please contact us for technical information and sample testing.