By quanyu lee

2025-08-26 06:44:55

Ribbon Cable Knowledge Sharing: Installation, Cleaning and Customization Services

In today's era of rapid electronic device development, stable signal transmission and efficient cabling are paramount. Ribbon cable, with its flat, compact structure, excellent flexibility, and reliable performance, has become an indispensable component in computers, home appliances, automotive electronics, and industrial control systems. This article will provide a comprehensive understanding of ribbon cable, covering its definition, types, applications, installation, and maintenance, to help you better understand and correctly use this important connection component.

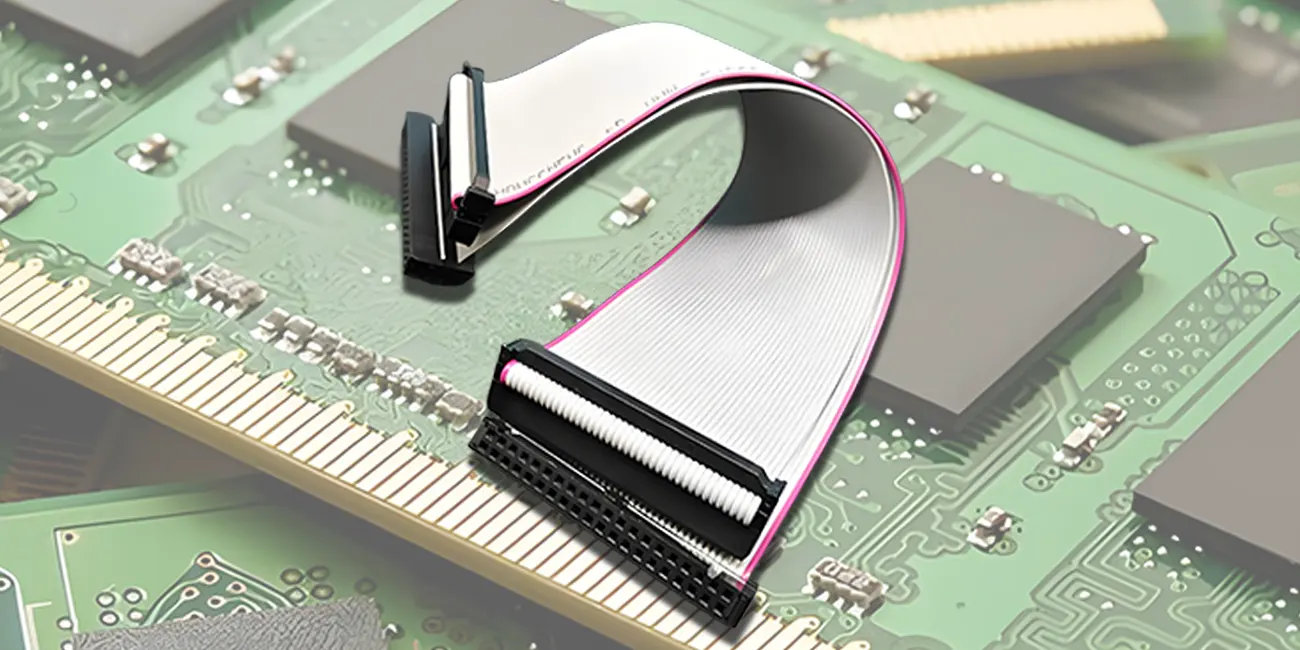

1. What is a ribbon cable?

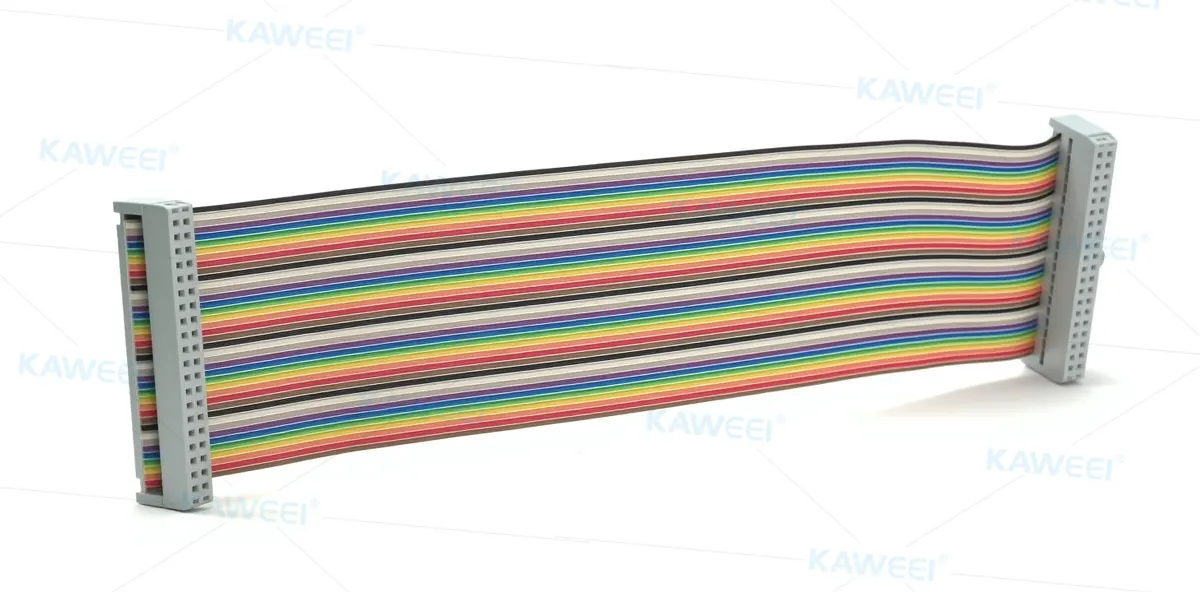

Ribbon cable, also known as flat cable, is a type of cable consisting of multiple parallel conductors. Its name derives from its appearance, which resembles a colorful ribbon. Ribbon cable is often used in scenarios requiring multiple signal lines to be transmitted in parallel. It offers advantages such as space savings, neat wiring, and easy installation.

2. What types of ribbon cables are there?

Ribbon cables can be categorized into the following types based on their material and purpose:

- Flat Ribbon Cable: Commonly used inside computers, such as connecting hard drives and optical drives to motherboards.

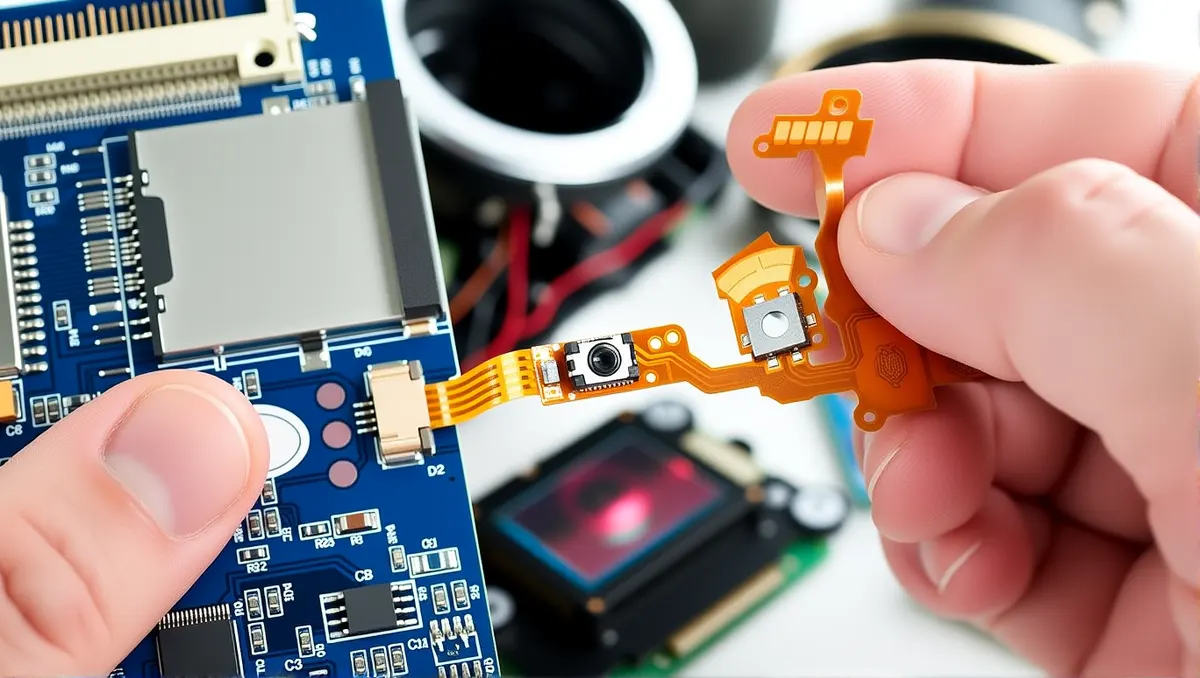

- Flexible Flat Cable (FFC): Highly flexible, commonly used in compact electronic devices such as mobile phones, laptops, and printers.

- Shielded Ribbon Cable: Used in environments with high levels of electromagnetic interference to ensure signal stability.

- High-temperature or wear-resistant ribbon cables: Suitable for industrial automation and specialized environments.

3. What electronic devices are suitable for using ribbon cables?

Due to its compactness and high efficiency, ribbon cables are primarily used in:

- Computers and servers (interface connections for hard drives, motherboards, graphics cards, etc.)

- Consumer electronics (TVs, printers, cameras, audio equipment)

- Medical equipment (internal connections for testing instruments)

- Automotive electronics (instrument panels, car navigation systems)

- Industrial automation equipment (PLC controllers, robotic control systems)

4. How to Replace the Ribbon Cable Connector

- Turn off the power and secure the device.

- Find the slots on each end of the cable and gently release the latches.

- Remove the old ribbon cable and insert the new one, ensuring the correct orientation and pin alignment.

- After ensuring the cable is securely fastened, power on the device and test it.

5. Can ribbon cables be cleaned?

Direct cleaning of ribbon cables is not recommended, as moisture and detergents may damage the insulation or metal conductors. If cleaning is necessary, wipe the surface with a dry, soft cloth or an alcohol-based swab to prevent corrosion and oxidation.

6. How to Remove the Ribbon Cable

- Disconnect the power cord first to prevent short circuits.

- Release the clips or retaining bars on the connector.

- Pull out gently and evenly, avoiding excessive force to avoid damaging the connector.

7. How to Disconnect a Ribbon Cable

When disconnecting a ribbon cable, avoid folding or pulling on it:

- Hold the connector, not the cable itself.

- Pull out slowly, ensuring all contact points are intact.

- For FFCs, unlock the connector latch before removing the cable.

8. FAQs Frequently Asked Questions About Ribbon Cables

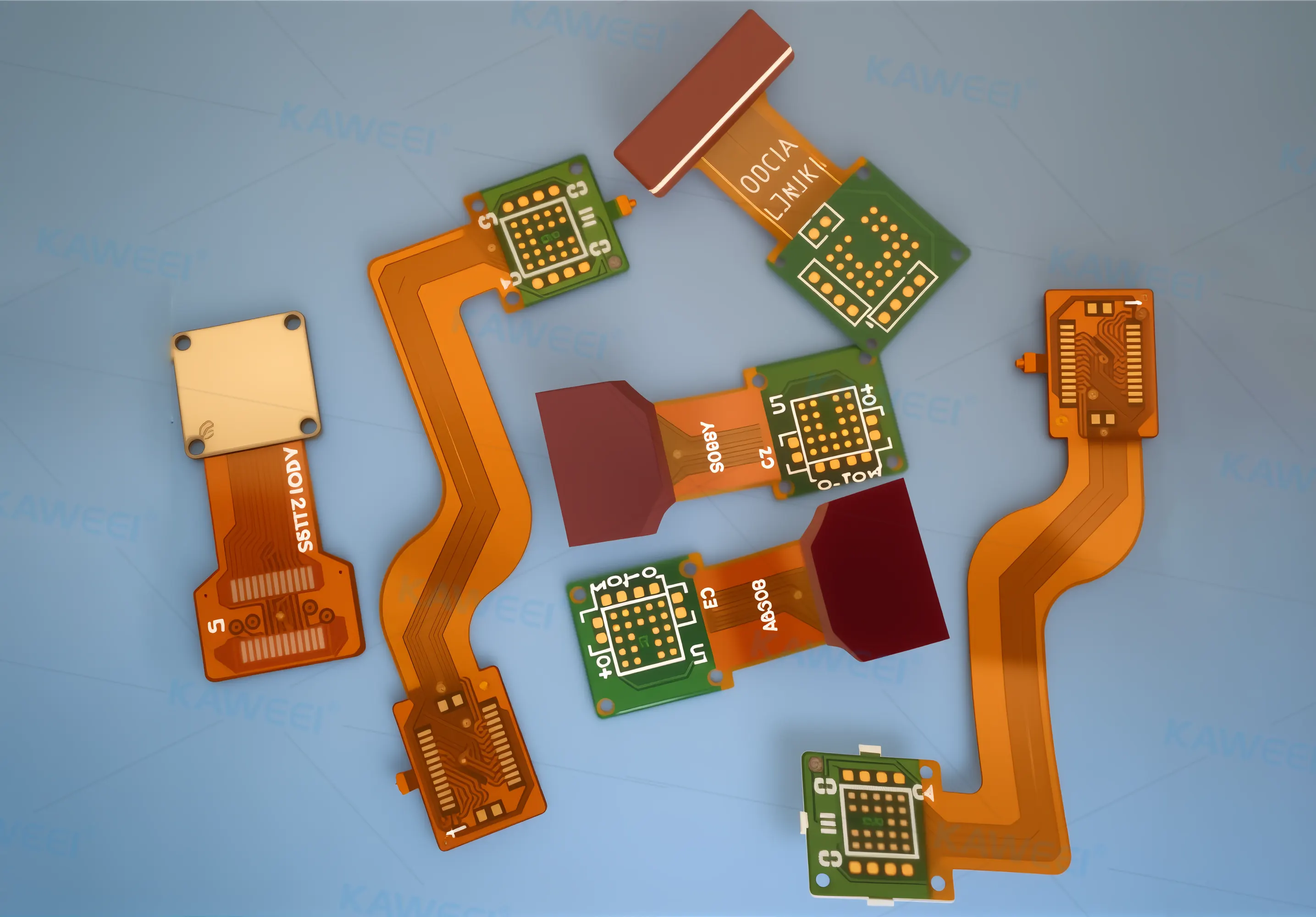

Q1: Can ribbon cables be customized?

A: Yes, ribbon cables can be customized to meet device requirements, including length, wire diameter, and pin count. For example, Kaweei Custom Wire Harness Factory offers a variety of custom ribbon cables and wire harnesses, catering to diverse needs from consumer electronics to industrial equipment.

Q2: What is the lifespan of a ribbon cable?

A: It depends on the operating environment and the material. Generally, it can last 5-10 years under normal use.

Q3: If a ribbon cable is damaged, can it be repaired?

A: Minor damage can be repaired with insulating tape, but for long-term use, it is recommended to replace it.

Q4: What is the difference between a ribbon cable and a regular cable?

A: Ribbon cables have multiple parallel wires and are arranged compactly, making them suitable for precision equipment with limited space. Regular cables are more suitable for single-wire or complex wiring scenarios.

9. Conclusion

Ribbon cable, with its flexibility, compactness, and efficiency, plays a vital role in electronic devices. Its applications are ubiquitous, from computers to automotive electronics, from home appliances to industrial control. Proper installation, cleaning, and maintenance can extend its service life. For projects requiring specialized specifications, choosing a custom ribbon cable manufacturer like Kaweei Wire Harness Custom Factory is a reliable choice for guaranteed quality and performance.