By quanyu lee

2025-09-11 11:59:05

Waterproof Wiring Harness Knowledge Sharing: Applications, Testing, and Selection Guide

In today’s rapidly evolving electrical and electronic industries, ensuring system reliability in harsh environments is more critical than ever. A waterproof wiring harness plays a vital role in protecting circuits from moisture, dust, and corrosion, making it indispensable in automotive, marine, industrial, and outdoor applications. This article provides a comprehensive knowledge-sharing guide, covering definitions, testing methods, connector selection, key elements, industry use cases, and expert recommendations for choosing the right manufacturer.

1. What is a waterproof wiring harness?

A waterproof wiring harness is a specially designed and processed electrical connection assembly that can maintain circuit stability and safety in humid, rainy, oily, or high-moisture environments. It is typically composed of wires, sealed sheaths, waterproof connectors, and insulation materials. Waterproof harnesses are widely used in automobiles, ships, outdoor equipment, and industrial control systems.

2. Why is a Waterproof Wiring Harness Important?

In electrical systems, moisture intrusion can cause short circuits, corrosion, or even electrical fires. The waterproof wiring harness extends system lifespan, improving equipment reliability and reducing maintenance costs. This is especially vital in applications such as automotive, construction machinery, medical equipment, and outdoor lighting.

3. How is a Waterproof Wiring Harness Tested?

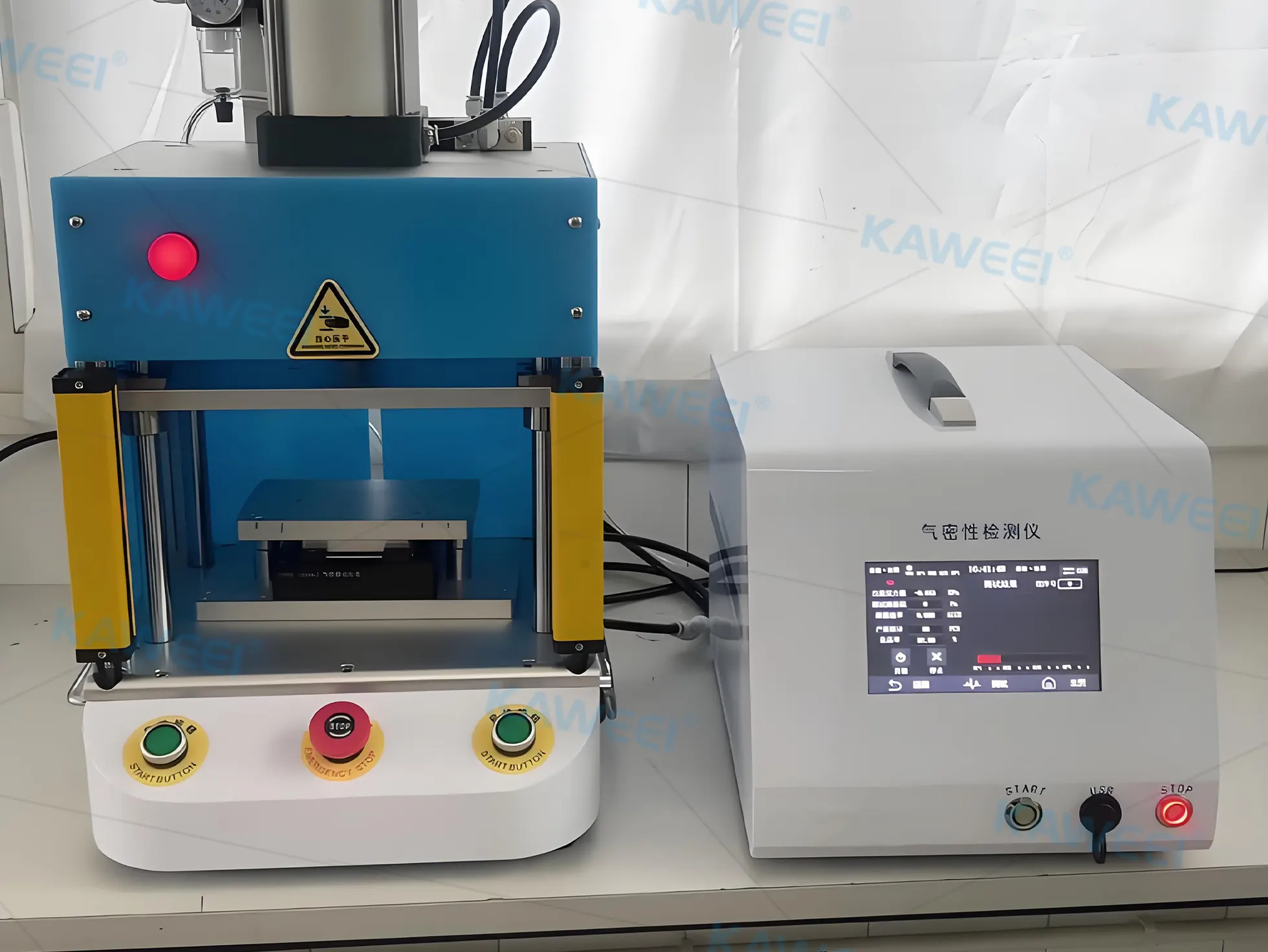

Waterproof wiring harness testing typically involves rigorous inspection before leaving the factory, including:

- Air-tightness testing: pressurizing and detecting leaks to ensure no water ingress under submerged or humid conditions.

- IP rating testing: verifying waterproof and dustproof performance according to international standards (e.g., IP67, IP68).

- Salt spray testing: particularly for marine wiring harnesses and outdoor devices, to ensure anti-corrosion performance.

4. How to Choose a Waterproof Connector?

When selecting a waterproof connector, consider the following key aspects:

- Protection rating: Choose the proper IP level for your application.

- Material: high-temperature and corrosion-resistant engineering plastics or metal housings.

- Durability: ensure long-term insertion/extraction without failure.

- Seal quality: O-rings and rubber seals must have excellent aging resistance.

5. Which Industries Require Waterproof Wiring Harnesses?

Waterproof wiring harness applications are extensive, including:

- Automobiles and new energy vehicles

- Marine and offshore engineering

- Outdoor lighting and surveillance systems

- medical equipment

- Industrial automation and robotics

- Agricultural machinery and smart devices

6. Are Automotive Wiring Harnesses Waterproof?

Some automotive waterproof wiring harnesses do have waterproof capability, especially those in engine compartments, chassis, and external lighting systems, which often use waterproof connectors and sealed sheaths. However, not all automotive wiring harnesses are fully waterproof, so specific requirements must be defined during customization.

7. Key Elements of a Waterproof Wiring Harness

- High-quality sealing design (to prevent moisture penetration)

- Corrosion-resistant materials (e.g., tinned copper wires, waterproof adhesives)

- Certified protection levels (such as IP67/IP68)

- Proper routing and sheath protection

8. Choosing the Right Waterproof Wiring Harness Manufacturer

When selecting a waterproof wiring harness supplier, reliability and customization capabilities are crucial. For instance, Kaweei Wiring Harness Custom Factory can provide services such as waterproof certification, customized connector design, and mass production, ensuring products meet diverse application requirements.

9. FAQ – Common Questions About Waterproof Wiring Harnesses

Q1: What is the lifespan of a waterproof wiring harness?

Typically 5–10 years, depending on the usage environment and material quality.

Q2: Can a waterproof wiring harness work underwater long-term?

Some high-grade harnesses (e.g., IP68) can withstand short-term immersion, but long-term use requires a special design.

Q3: Can a waterproof wiring harness be repaired?

In most cases, repair is difficult; replacement or factory customization is recommended.

Q4: Can waterproof wiring harnesses support high voltage?

Yes, but the insulation and waterproof rating must match the design requirements.

10. Conclusion

As a critical component of electrical systems, waterproof wiring harnesses effectively resist risks caused by moisture and water, ensuring long-term stable operation of equipment. From testing methods to connector selection and industry applications, every aspect impacts performance. Choosing a professional manufacturer such as Kaweei Wiring Harness Custom Factory not only ensures product reliability but also provides tailored solutions for specific needs.