By quanyu lee

2025-09-10 09:45:17

EMC Cable Guide:Definition, Applications, and Design Types

With the rapid development of new energy vehicles, 5G communications, industrial automation, and smart healthcare, electrical systems are facing unprecedented challenges of electromagnetic interference. Ensuring stable operation in complex environments has become a critical issue across industries. As a key part of electromagnetic compatibility (EMC) design, EMC cable not only determines the safety and reliability of electrical systems but also directly affects whether a product can pass international EMC standards. This article explores the core concepts of EMC, the applications of EMC cable in different industries, and common design approaches, providing engineers and professionals with a comprehensive understanding of its value and trends.

What is an EMC Cable?

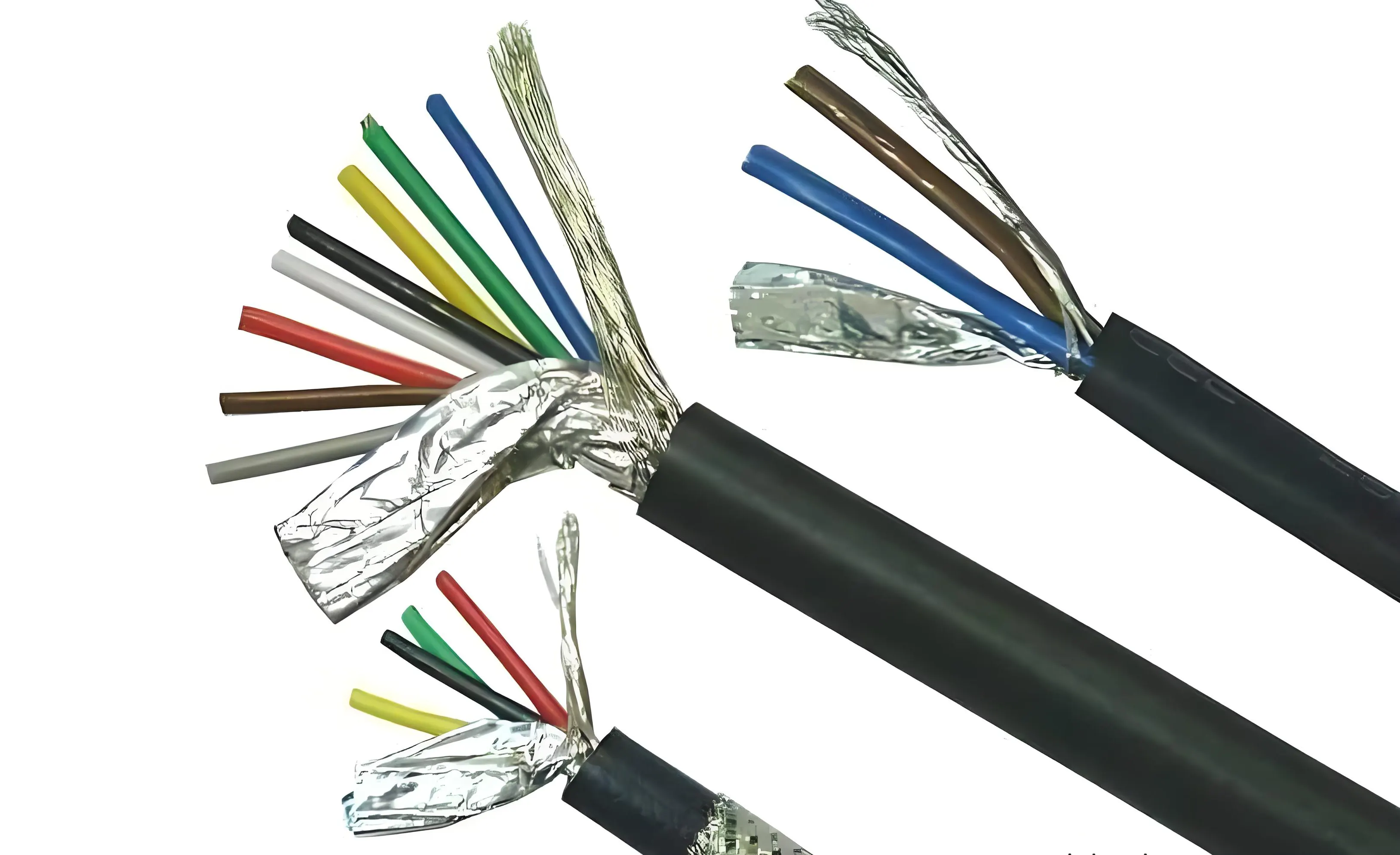

An EMC cable refers to wiring designed to meet EMC requirements in electrical systems and electronic equipment. Through optimized cable routing, grounding, and shielding, it reduces EMI (Electromagnetic Interference) and EMS (Electromagnetic Susceptibility), ensuring stable performance in complex electromagnetic environments.

Definition of EMC

- EMC (Electromagnetic Compatibility): The ability of a device to operate normally in its electromagnetic environment without causing excessive interference to other devices.

- EMI (Electromagnetic Interference): Undesirable electromagnetic energy affecting the operation of equipment.

- EMS (Electromagnetic Susceptibility): The degree to which equipment is sensitive to external electromagnetic interference.

In short, EMC is the system’s capability to adapt to its environment, EMI is the interference source, and EMS is the ability to withstand interference.

What is the Difference Between EMI and EMC?

- EMI: The interference itself (the problem).

- EMC: The solution (ensuring the system continues to work reliably).

Simply put, EMI is the “illness,” and EMC is the “ability to cure the illness.”

What is EMC in Electrical Engineering?

In electrical engineering, EMC requires that:

- Equipment does not exceed emission limits set by international standards.

- Equipment can resist external interference and maintain stable operation.

This is particularly important in automotive, industrial automation, telecommunications, and aerospace applications.

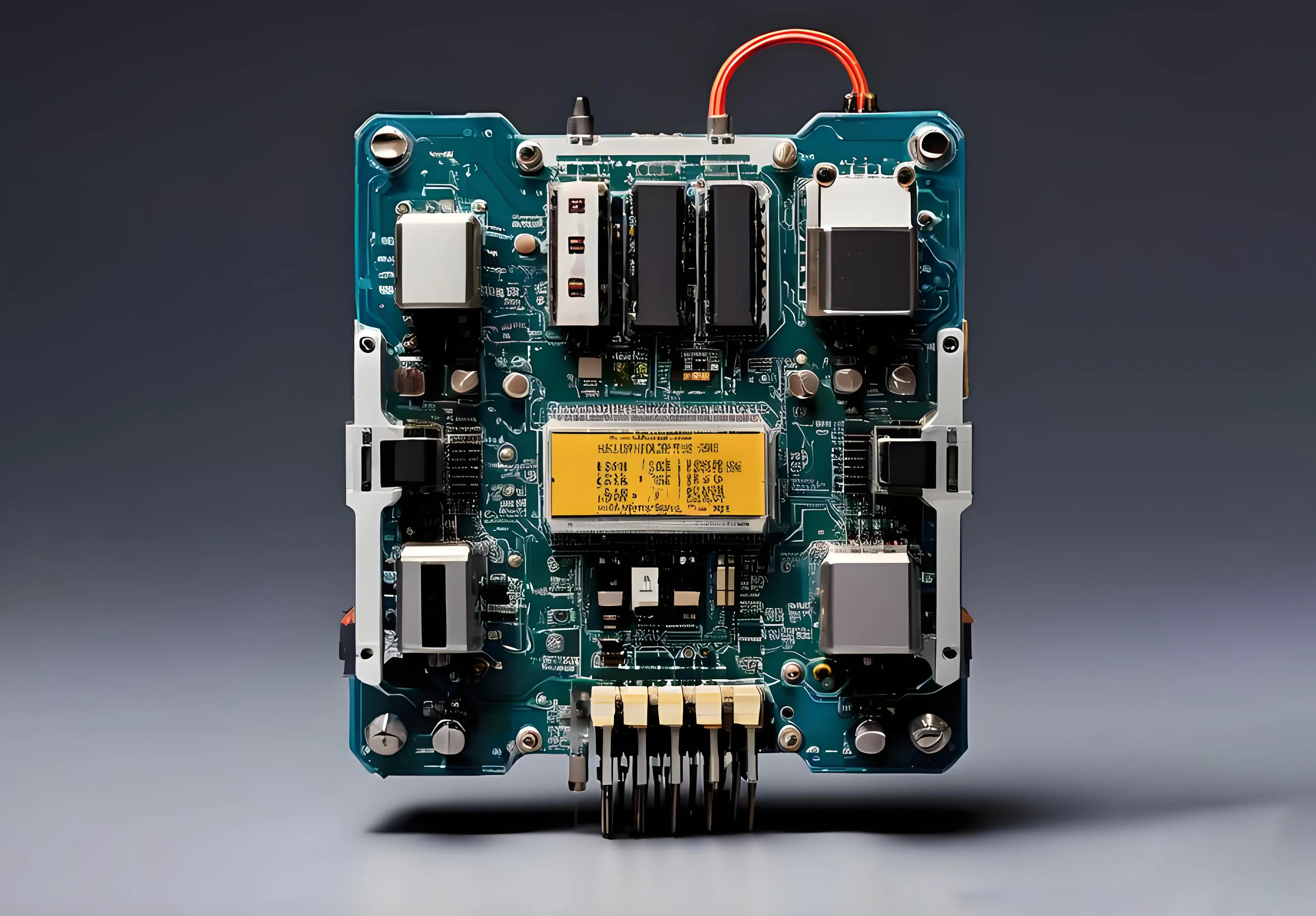

What is an EMC Connector?

An EMC connector is a connector with built-in electromagnetic shielding, often used in automotive electronics, medical devices, and aerospace communication systems. Its metallic housing and shielding design effectively reduce electromagnetic leakage.

Applications of EMC Cable

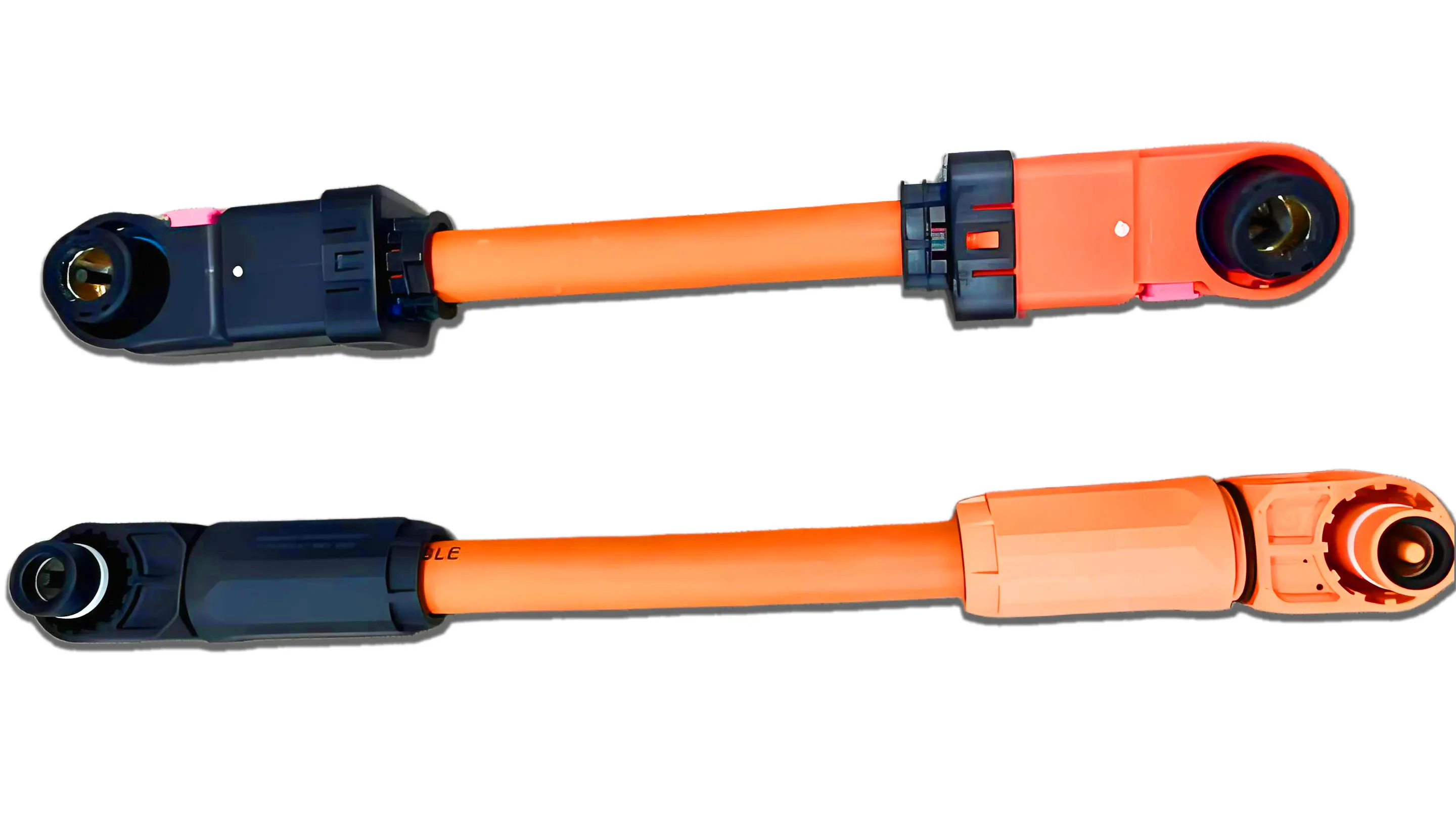

- Automotive: High-voltage cable routing in electric vehicles, in-vehicle radar, and ADAS systems.

- Industrial: Robots, PLC control cabinets, and smart factories.

- Medical: MRI, ultrasound, and other devices requiring extremely strict electromagnetic environments.

- Telecommunications: Base stations, data centers, fiber optic and coaxial transmission systems.

- Aerospace: Flight control systems and satellite communication.

Types of EMC Cable Design

- High-voltage EMC cable design: Multi-layer shielding and optimized routing in EVs.

- Grounding distribution EMC design: Preventing ground loops to reduce interference propagation.

- Shielded cable design: Using braided metal shielding, aluminum foil shielding, or double-layer structures.

- Differential wiring design: Common in high-speed data transmission, reducing radiation.

FAQ: Common Questions About EMC Cable

Q1: Why are EMC cables important in electric vehicles?

A: High-voltage cables can generate strong electromagnetic radiation, which may interfere with low-voltage control and communication systems.

Q2: Is a shielded cable always required to meet EMC requirements?

A: Not necessarily. Proper grounding, routing, and filtering can also significantly improve EMC design performance.

Q3: What are the common EMC tests?

A: Conducted emissions, radiated emissions, conducted immunity, and radiated immunity tests.

Q4: How do EMC connectors differ from regular connectors?

A: EMC connectors provide electromagnetic shielding, while regular connectors only serve electrical and mechanical connection purposes.

Conclusion

EMC cable is an essential part of modern electrical system design. It not only ensures that devices operate safely and reliably in complex environments but also determines whether products comply with international standards. With the growing global emphasis on electromagnetic compatibility, future EMC cable design will increasingly rely on simulation tools, advanced shielding materials, and systematic engineering approaches. From electric vehicles to smart manufacturing, from medical devices to aerospace systems, the importance of EMC cable will continue to rise as a cornerstone of reliable and compliant electrical systems.