By quanyu lee

2025-09-08 09:26:22

Electric vehicle wiring harness analysis: types, design innovations and future development trends

With the rapid global adoption of electric vehicles, EV wiring harnesses have become a core component supporting their electrical systems. Compared to traditional fuel-powered vehicles, EVs require more efficient, safer, and smarter wiring harness solutions to meet the demands of high-voltage power supply, intelligent connectivity, and lightweight design. This article will provide a comprehensive understanding of the characteristics, innovative trends, and future developments of EV wiring harnesses.

1. What is an electric vehicle wiring harness?

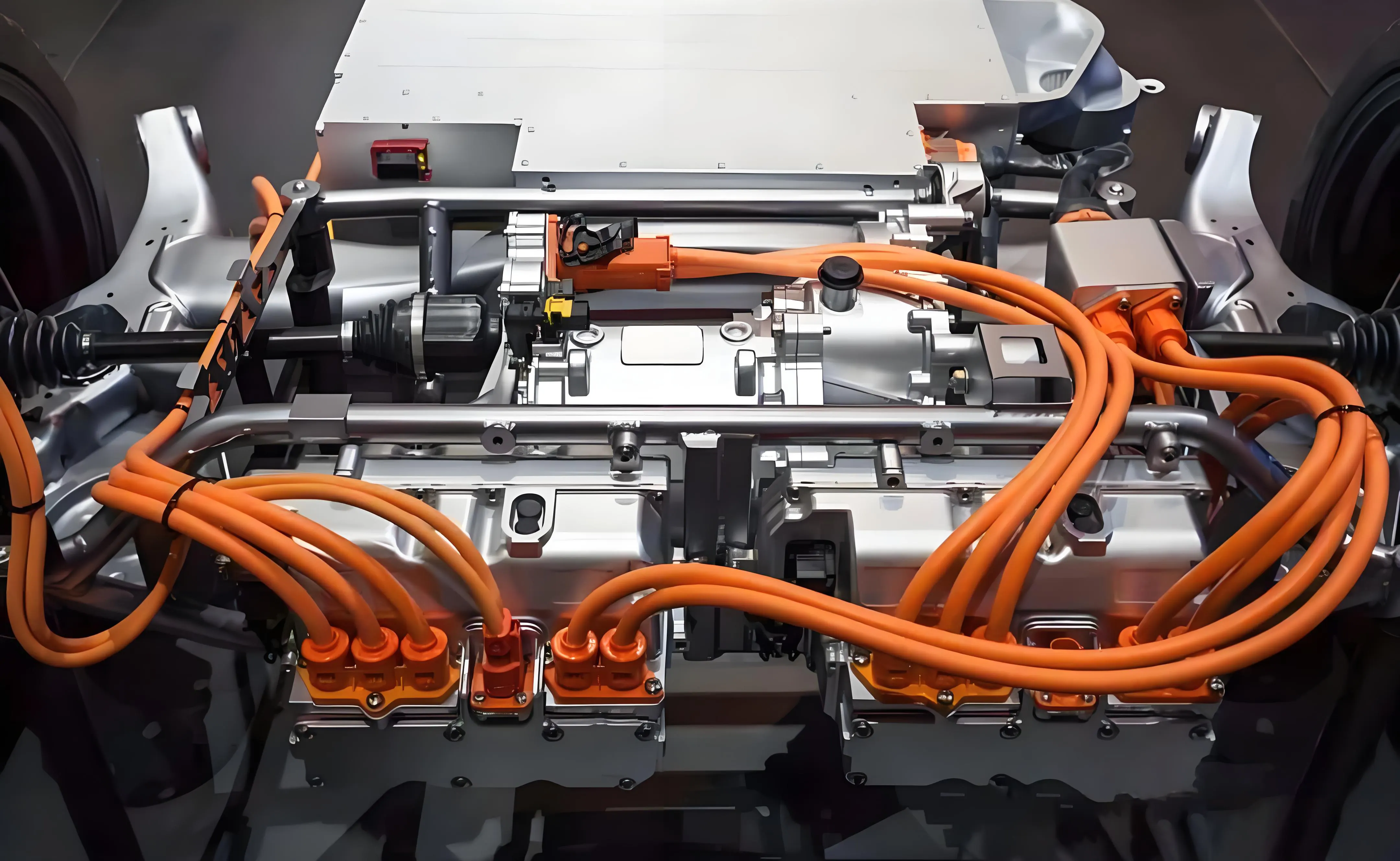

An EV wiring harness is an electrical connection system used to transmit power and signals in electric vehicles. It consists of cables, connectors, sheaths, and fixtures, ensuring efficient communication and power supply between electric vehicle batteries, motors, controllers, and various sensors.

2. What is the difference between electric vehicle wiring harnesses and automotive wiring harnesses?

Compared to traditional automotive wiring harnesses, electric vehicle wiring harnesses must withstand higher voltages and currents, and therefore have stricter standards for insulation, protection, and heat dissipation. At the same time, EV wiring harnesses must support intelligent functions, such as high-speed data transmission between the battery management system (BMS) and the vehicle's communication system.

3. Why do electric vehicles change wiring harness design?

The core of electric vehicles is the high-voltage battery and electric drive system, which requires significant upgrades in wiring harnesses in terms of safety, weight, and durability. The design must reduce energy loss and prevent electromagnetic interference (EMI), while also taking into account vehicle lightweighting to increase driving range.

4. What are the wiring harnesses for electric vehicles?

Common EV wiring harnesses include:

- High-voltage power harness: Connects the battery and motor, providing the primary power supply.

- Low-voltage control harness: Responsible for internal vehicle control and signal transmission.

- Charging harness: Supports AC charging and DC fast charging.

- In-vehicle communication harness: Enables data exchange and connected vehicle functionality.

5. Why are lightweight and sustainable materials driving innovation?

To extend the range of electric vehicles, lightweight design is becoming a trend. Aluminum alloy conductors, tinned copper, and high-performance composite materials are widely used. Furthermore, environmental regulations are driving the use of recyclable and biodegradable materials in electric vehicle wiring harnesses to reduce carbon emissions.

6. How did high-voltage, high-speed wiring harnesses emerge?

With electric vehicles moving toward 800V high-voltage platforms and intelligent driving, high-voltage, high-speed wiring harnesses have emerged. These wiring harnesses support fast charging and high-speed data transmission, providing stable support for autonomous driving systems and in-vehicle computing platforms.

7. What is a modular wiring harness?

A modular wiring harness is a flexibly configurable design. This modularity allows automakers to quickly adjust wiring harness layouts to suit different vehicle models or configurations, improving production efficiency and reducing maintenance costs.

8. What is a smart wiring harness?

Smart wiring harnesses are equipped with sensors and data interfaces that monitor current flow, temperature, and signal transmission status in real time. This facilitates predictive maintenance, improves vehicle safety and reliability, and is a key development direction for future new energy vehicles.

9. Wiring Harness Automation is Accelerating

With the surge in electric vehicle production, wiring harness manufacturing is undergoing accelerated automation. Automated equipment and digital processes are improving production efficiency and consistency, driving the industry's transition to smart manufacturing.

10. Frequently Asked Questions (FAQs)

Q1: What is the lifespan of an electric vehicle's wiring harness?

It generally lasts about the same as the entire vehicle, approximately 10 years or more.

Q2: Can electric vehicle wiring harnesses be customized?

Yes, many companies offer customization based on vehicle model requirements. For example, Kaweei's custom wiring harness factory offers high-voltage, high-speed, and modular electric vehicle wiring harness solutions to meet the diverse project needs of our customers.

Q3: Is it difficult to maintain an electric vehicle's wiring harness?

Thanks to their modular and intelligent design, modern electric vehicle wiring harnesses have relatively low maintenance costs.

11. Conclusion

As a crucial foundation for the new energy vehicle industry, electric vehicle wiring harnesses are undergoing a comprehensive upgrade from high-voltage safety to intelligent connectivity. Lightweighting, modularization, intelligence, and automation are the core development directions. With continuous technological innovation in the industry, electric vehicle wiring harnesses will continue to drive the green and intelligent transformation of the future automotive industry.