By quanyu lee

2025-10-14 09:56:39

A complete analysis of the types and applications of PVC insulated electronic wiring harnesses

With the diversification of modern electronic devices and industrial systems, PVC-insulated electronic wire harnesses have become essential components for connectivity, power supply, and signal transmission. Due to their stable insulation, excellent flexibility, and low cost, these wire harnesses are widely used in a variety of fields, including home appliances, automobiles, industrial control, and communications equipment.

1. What is a PVC-insulated wiring harness?

PVC (polyvinyl chloride) is a commonly used electrical insulation material with excellent resistance to wear, oil, flame, and chemical corrosion.

A wiring harness with PVC insulation typically consists of a conductor (copper core or tinned copper wire), insulation, connectors, terminals, and an outer jacket, enabling reliable transmission of signals, data, or power.

Key features include:

- Excellent dielectric strength and electrical insulation performance

- Suitable for various processing methods (crimping, welding, and IDC piercing)

- Relatively low cost and high cost-effectiveness

- Customizable flame-retardant or flexible options are available to suit different application environments

2. Common Types of PVC Insulated Electronic Wiring Harnesses

Depending on the connection method, structural form, and application scenario, PVC-insulated electronic wiring harnesses can be divided into the following categories:

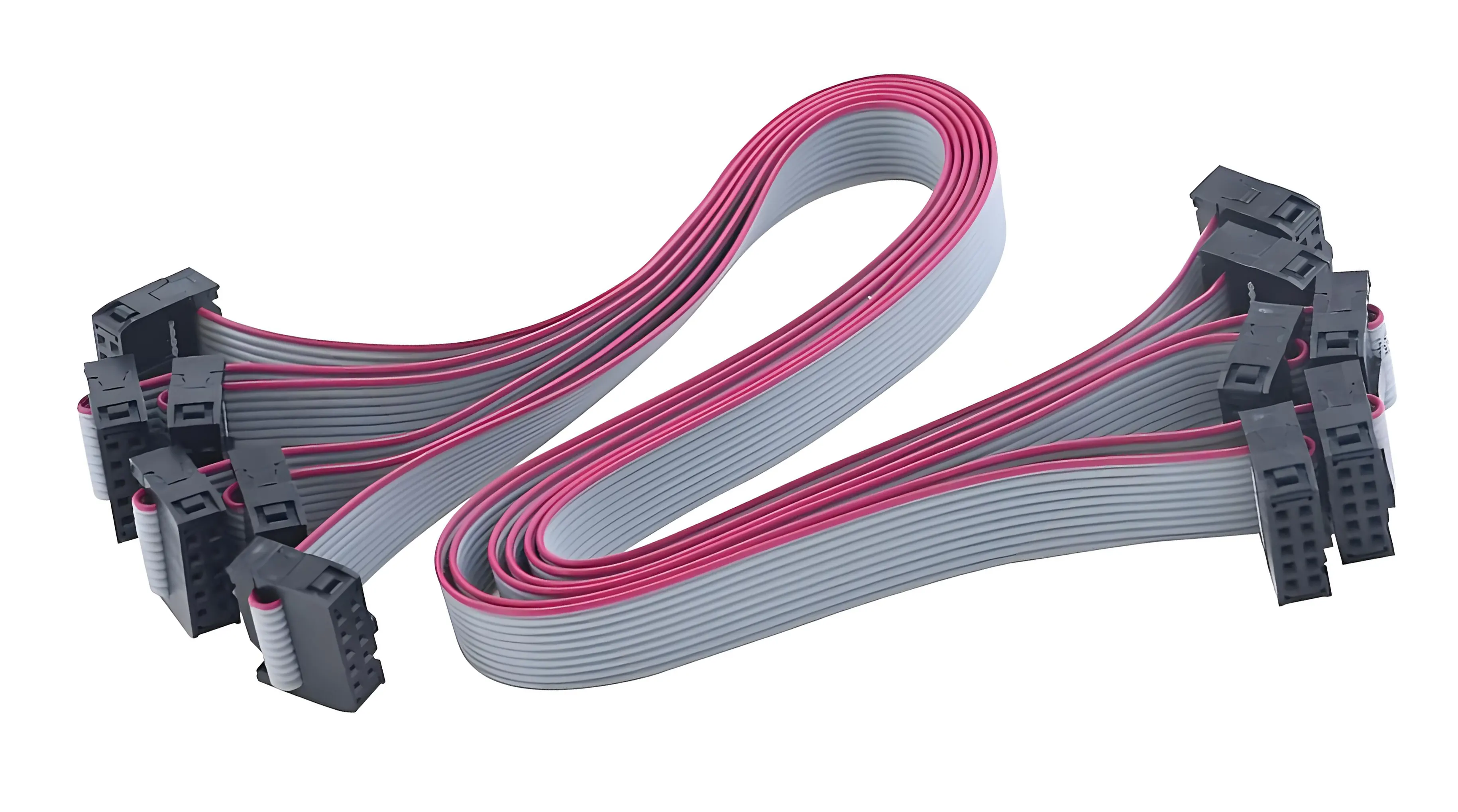

1. Insulation Displacement Connection Harness (IDC Harness)

Features: Quick assembly through insulation displacement connection, no stripping required.

Common Type: IDC Flat Ribbon Cable Harness

Applications: Printers, communications equipment, signal transmission modules.

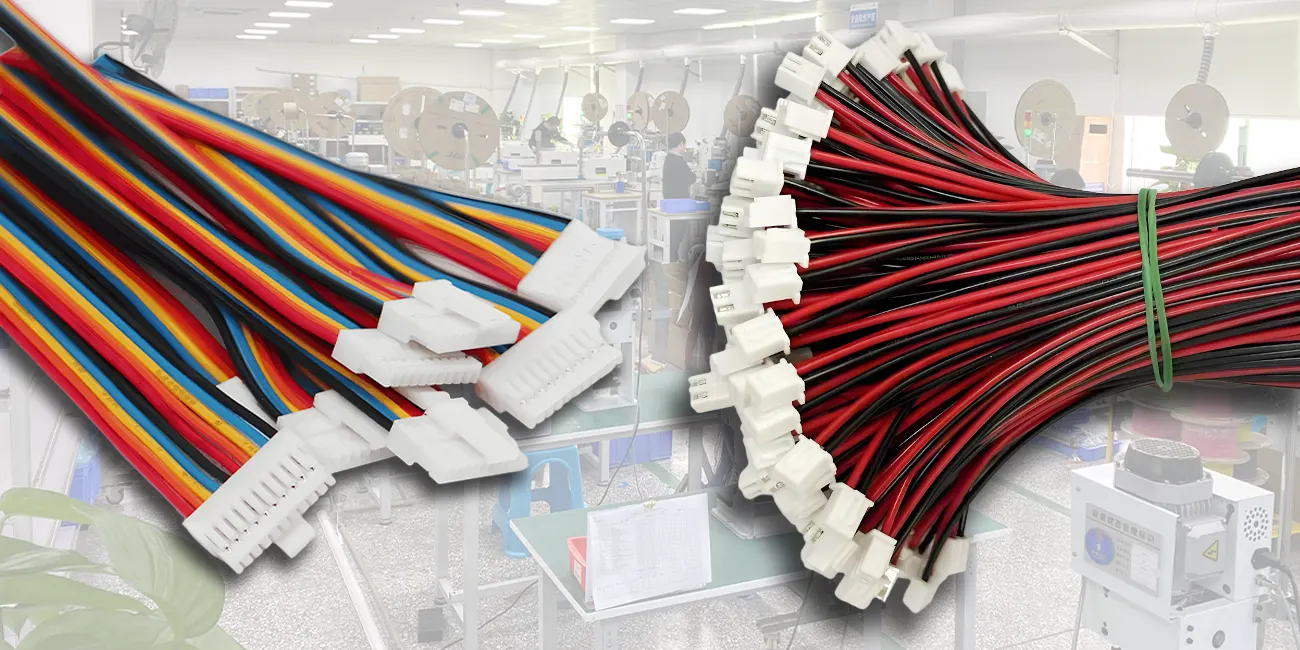

2. Crimp-Type Harness

Features: Metal terminals and conductors are mechanically crimped together, providing reliable contact and excellent vibration resistance.

Common brands: JST, Molex, TE Connectivity, etc.

Applications: Automotive electronics, home appliance control systems, and medical equipment.

3. Plug-in Harness

Features: Standard plug connector for easy maintenance and replacement.

Examples: DC power cables, USB harnesses, jumper cables.

Applications: LED lighting, power adapters, small instruments.

4. Branched Harness

Features: One end splits into multiple branches, allowing connection to multiple functional modules.

Applications: Automotive instrument panels, control box internal wiring, and industrial equipment systems.

3. Typical structural forms

| Structure type | Features | Common examples |

| Flat Cable Harness | Save space, parallel signal transmission | IDC cable, FFC flat cable |

| Round Cable Harness | Good flexibility and excellent anti-interference performance | DC power supply cable, sensor extension cable |

| Shielded Harness | Prevent signal interference, suitable for industrial and communication equipment | RS232 signal line, CAN bus wiring harness |

| Board-to-Board Harness | Connect signals between different PCB boards | Electronic control module connecting wire |

4. Main application fields of PVC-insulated electronic wiring harness

PVC-insulated electronic wiring harnesses have a wide range of applications, with specific product examples corresponding to different fields.

These include:

- Home appliance applications include PCB connectors, AC power cables, and motor wiring harnesses.

- Automotive applications include instrument panel wiring harnesses, lighting control harnesses, and sensor cables.

- LED lighting applications include series control cables and power extension cables.

- Industrial automation applications include control signal harnesses and PLC interface harnesses.

- Communications applications include IDC data cables and RJ45 network harnesses.

5. Key Factors When Selecting PVC-Insulated Electronic Wiring Harnesses

The following factors should be considered comprehensively when selecting a PVC-insulated wiring harness:

Operating voltage and current: Select a conductor with a matching cross-section.

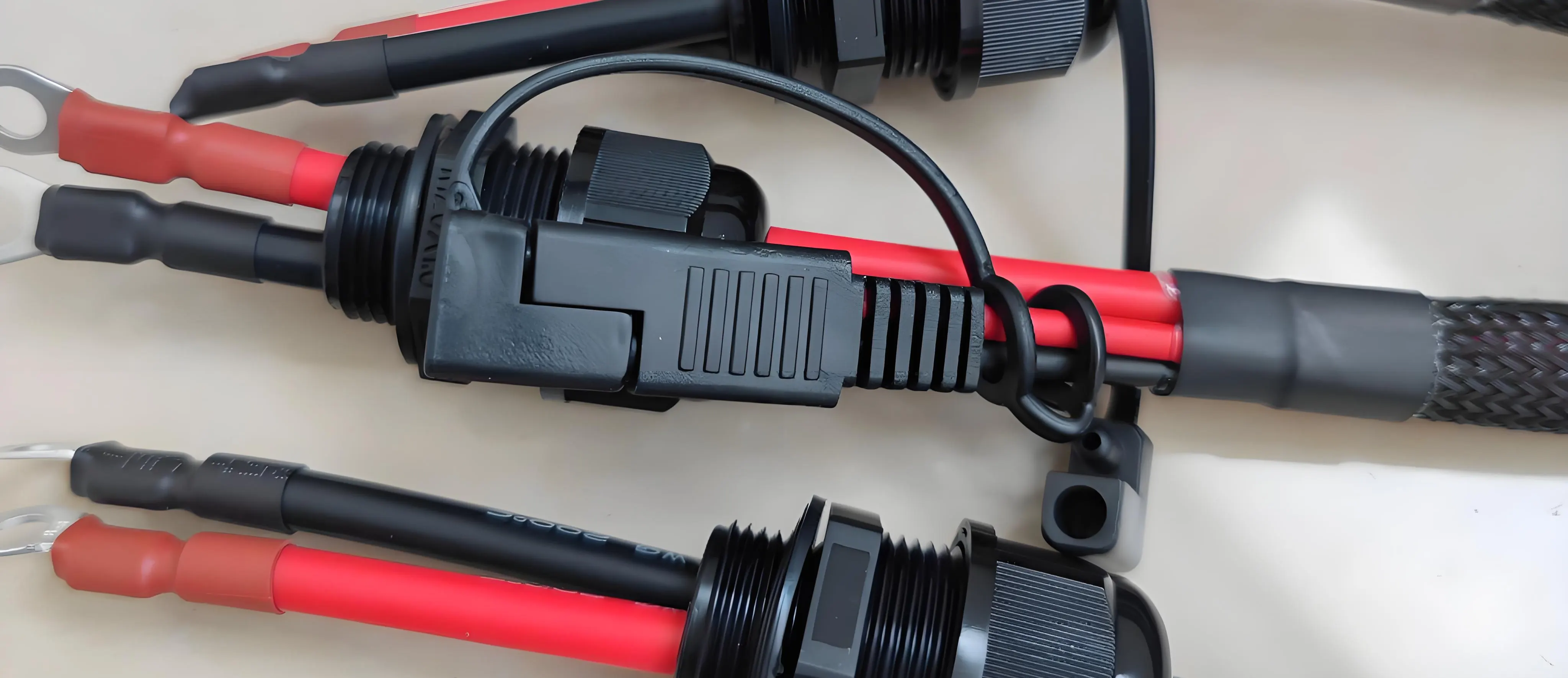

Usage environment: For high-temperature, high-humidity, oily, or outdoor environments, choose weather-resistant PVC.

Connection methods: IDC, crimping, welding, etc.

Flexibility and bending requirements: Wire harnesses used for moving parts should use highly flexible PVC.

6. Why Choose Wire Harness Assembly?

As a professional manufacturer specializing in custom electronic wire harnesses and cable assemblies, WIRE HARNESS ASSEMBLY provides a comprehensive solution from design and material selection to assembly and testing.

Our strengths include:

Years of OEM/ODM experience

Support for standard connectors such as JST, Molex, TE, AMP, and IDC

Strict adherence to IPC/WHMA-A-620 international wiring harness standards

Custom solutions for waterproofing, anti-interference, and high-temperature resistance

Whether you need home wiring harnesses, automotive wiring harnesses, or industrial control wiring harnesses, WIRE HARNESS ASSEMBLY can provide you with high reliability and cost-optimized solutions.

FAQ

Q1: Can PVC-insulated electronic wiring harnesses be used outdoors?

A: Standard PVC wiring harnesses are more suitable for indoor environments. For outdoor use, choose a waterproof wiring harness with a waterproof sheath or one made of cross-linked PVC/PE material.

Q2: What is the difference between IDC cables and standard multi-core cables?

A: IDC cables have a parallel structure, suitable for high-speed signal transmission; standard multi-core cables have a round structure, which is more resistant to bending.

Q3: Can I customize specific lengths or terminal brands?

A: Of course. Wire Harness Assembly offers comprehensive customization services, including length, terminal type, jacket color, and packaging.

Q4. What is the difference between PVC-insulated electronic wiring harnesses and silicone wiring harnesses?

PVC wiring harnesses typically have a temperature range of -40°C to 105°C and offer excellent oil resistance and mechanical strength.

Silicone wiring harnesses are more suitable for high-temperature, high-flexibility environments (such as medical equipment and LED lighting).

For applications in ambient temperature or industrial environments, PVC wiring harnesses are a more economical and practical choice.

Q5. Can PVC-insulated electronic wiring harnesses pass environmental certification?

Yes. High-quality PVC-insulated wiring harnesses typically comply with international environmental standards such as RoHS and REACH. Some products also meet UL certification requirements, ensuring material safety, halogen-free, and environmentally friendly properties, making them suitable for export markets.

Q6. What is the lifespan of PVC-insulated wiring harnesses?

Under proper installation and normal use, PVC wiring harnesses generally have a service life of 5 to 10 years. For outdoor or high-temperature environments, choose models with UV protection and high heat resistance to extend their service life.