By quanyu lee

2025-08-13 02:36:49

Robot Cable Types and Applications Guide

Robot cables are special cables designed specifically for robotic systems and automated machinery. Unlike ordinary cables, they can withstand continuous bending, torsion, and harsh industrial environments. In modern industrial automation, they are key components that ensure stable power transmission, accurate signal communication, and long-life operation in high-frequency motion environments.

Types of Robot Cables

1. Power robot cables

Power robotic cables are used to provide electrical energy to robot motors, actuators, and other high-power components. These cables typically feature thicker copper conductors for increased current carrying capacity and durable insulation materials such as PVC, PUR, or TPE for mechanical protection.

Key Features:

- High voltage and high current carrying capacity

- Abrasion-resistant outer sheath

- Suitable for heavy-duty industrial robots

2. Signal type robot cable

Signal-type robotic cables are used to transmit control signals between sensors, controllers, and actuators. These cables require excellent shielding to prevent electromagnetic interference (EMI) in industrial environments.

Key Features:

- Twisted-pair or shielded construction reduces noise

- High-precision signal transmission

- Small diameter for easy wiring

3. Servo Robot Cables

Servo robot cables connect servo motors and controllers, typically combining power and signal lines within a single cable to reduce space and improve installation efficiency.

Key Features:

- Highly flexible copper conductor

- Hybrid design, including power and encoder cables

- Sustainable for long-term use under continuous bending and torsion conditions.

4. Hybrid Robotic Cables

Hybrid robotic cables integrate power, signal, and even data transmission functions into a single cable. This design reduces cable count and is ideal for compact robotic arms or automated production lines.

Key Features:

- Multifunctional Integration

- Lightweight and Space-Saving

- Customizable to meet specific automation needs

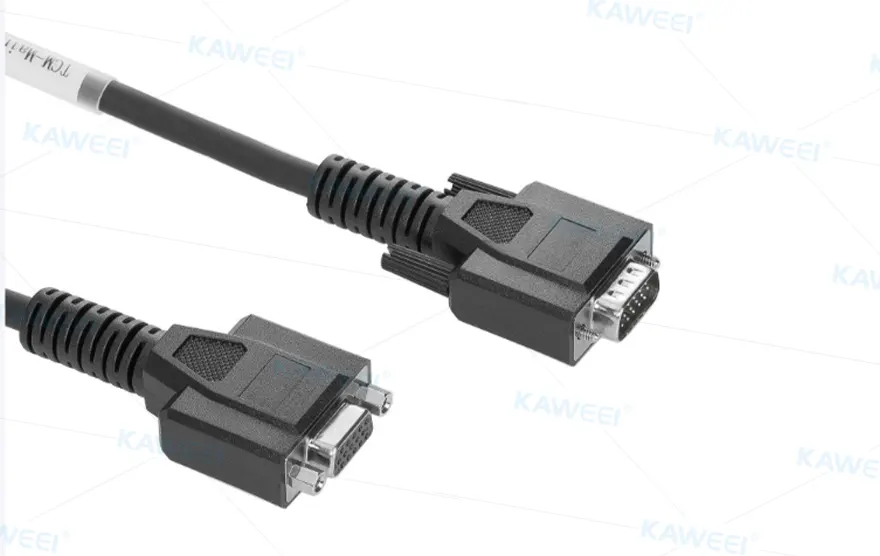

5. Data Robot Cables

Data robot cables are used for high-speed data transmission within robots, such as Ethernet, USB, or fieldbus systems.

Key Features:

- High-speed data transmission capability

- Twisted-pair shielding for electromagnetic interference resistance

- Maintains stable performance in highly flexible environments

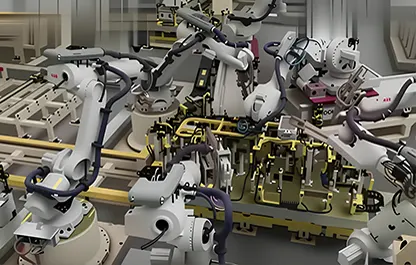

Application of Robot Cables in Industrial Automation

Manufacturing robotic arm

Robot cables are often used in articulated robotic arms for tasks such as welding, painting, and assembly. These cables must be able to withstand repeated bending and twisting without breaking down.

Automated Packaging System

On the packaging production line, robotic cables connect the conveyor belt, labeling machine, and handling robot, ensuring high-speed and precise production operations.

CNC Machine Tools and Material Handling

In CNC machining centers and automated warehouses, robotic cables provide stable support for motion control and communication, operating reliably even in environments with metal chips, dust, or oil.

Medical and Laboratory Automation

Compact and highly flexible robotic cables ensure precision and stability in medical robots, laboratory automation systems, and testing equipment.

Key Benefits of Using Robotic Cables

High Flexibility – Can withstand millions of bends without damage

High Durability – Resistant to abrasion, chemicals, oils, and UV rays

Signal Stability – Shielded design prevents data loss and interference

Compact Design – Saves space for complex robotic systems

In industrial automation, robotic cables aren't just components that connect things; they're the crucial foundation for robots to operate stably, accurately, and safely. Understanding the benefits of different types of robotic cables allows engineers and manufacturers to choose the most suitable one, improving production efficiency, reducing machine downtime, and extending equipment life.