By quanyu lee

2025-08-20 02:36:16

Battery Cables: A Comprehensive Guide

A battery cable is a power transmission cable specifically designed to connect batteries to electrical systems. It's widely used in applications requiring battery power, such as automobiles, motorcycles, ships, industrial equipment, and solar systems.

Its primary function is to reliably transmit battery energy to starter motors, generators, distribution boxes, or other electrical equipment.

1. Characteristics of battery cables

-

High Current Carrying Capacity

Batteries release a high current instantaneously during startup, so battery cables generally use thick conductors (such as copper or aluminum) to ensure low resistance and safe conduction.

-

Flexibility

Multiple strands of fine copper wire are twisted together, making routing easy in confined spaces and offering excellent flexibility.

-

Durability

Common insulation materials include PVC, XLPE, and EPDM, offering resistance to wear, high temperatures, oil, corrosion, and acids and alkalis.

-

Color Code

Red: Positive (+) cable

Black: Negative (−) cable

Clear colors facilitate installation and maintenance, preventing wiring errors.

2. Main types of battery cables

1. Battery Cable Assembly:

Connects the battery to the starter motor, generator, or power distribution box.

2. Battery Jumper Cable:

Used to jump-start the vehicle, comes with alligator clips, and is longer.

3. Battery Ground Cable:

Connects from the negative terminal of the battery to the vehicle body or engine, creating a ground loop.

4. Battery Interconnect Cable:

Used to connect battery packs in series or parallel.

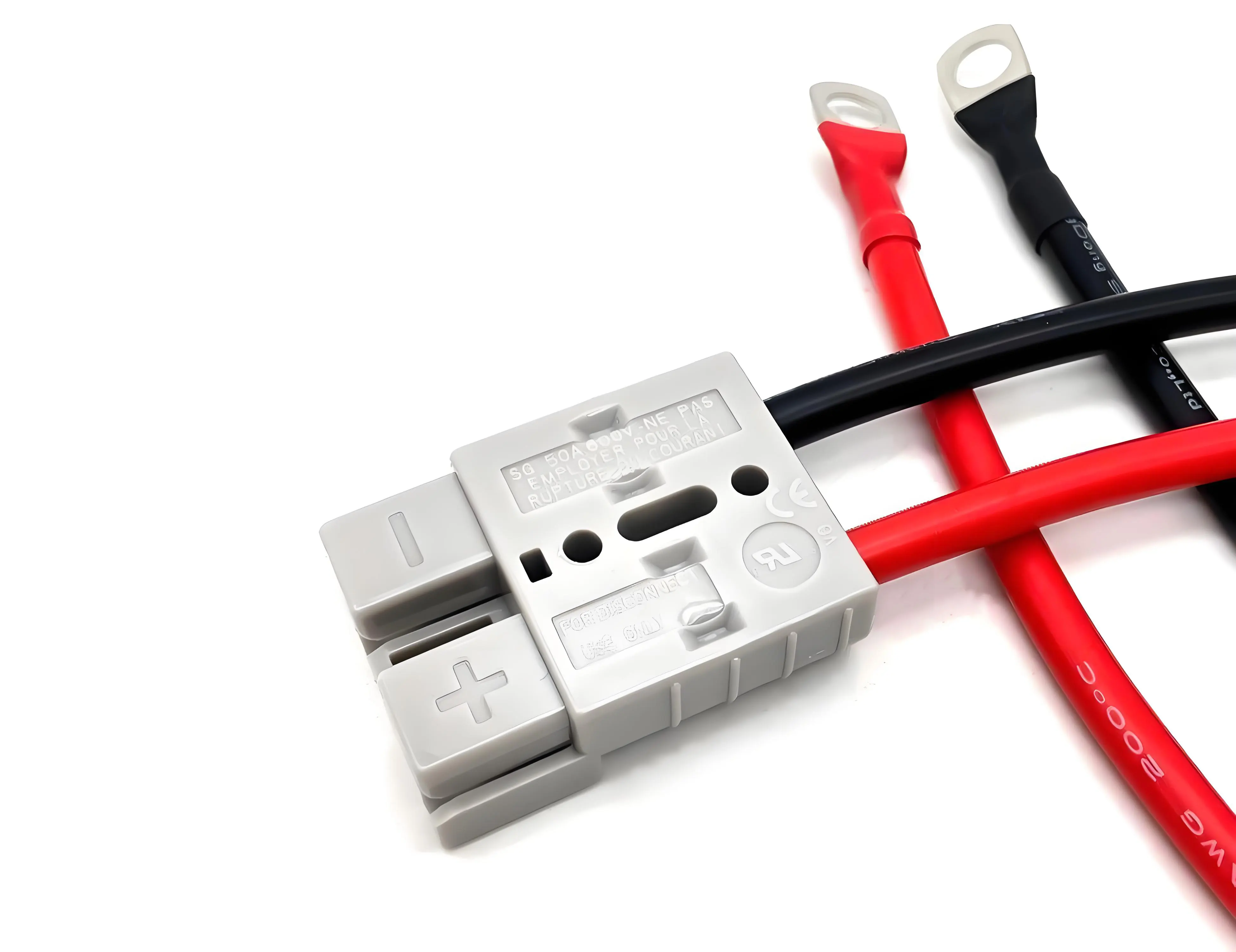

5. Battery Quick Disconnect Cable:

Features a quick-disconnect connector for easy assembly and disassembly, and maintenance.

6. Battery Charging Cable:

Connects the battery to the charger, ensuring stable charging.

3. Battery cable size standards

Battery cable size is primarily determined by wire diameter (AWG/mm²) and length.

AWG / mm²

- AWG (American Wire Gauge) is commonly used in North America. The smaller the number, the thicker the cable and the greater the current it can carry.

- China and Europe often use square millimeters (mm²).

- Common gauges: 6 AWG to 4/0 AWG (approximately 13mm² to 107mm²).

length

- 30cm – 50cm: Battery ground cable

- 1m – 2m: Car/motorcycle positive cable

- 3m – 6m: Battery jumper cable

- Longer: Solar energy storage systems, UPS battery packs

Tip: The longer the cable, the greater the voltage loss, so long cables require a thicker wire gauge to reduce losses.

4. Battery cable positive and negative poles

Positive (+) Cable

- Color: Red

- Connects: Battery (+) → Starter, Generator, Distribution Box, or Fuse Box

Negative (−) Cable

- Color: Black (sometimes brown or green)

- Connects: Battery (-) → Metal chassis or engine, creating a ground loop

Installation/Replacement Precautions

- When removing: First remove the negative (-) terminal, then the positive (+) terminal.

- When installing: First connect the positive (+) terminal, then the negative (-) terminal.

- Maintain correct polarity: red to red, black to black, and avoid reverse polarity.

5. How to Customize Battery Cables

1. Identify the application scenario.

- Automotive, motorcycle, marine, RV, solar energy storage, and industrial equipment.

2. Select wire diameter and current capacity.

- 6 AWG to 4/0 AWG (13mm² to 107mm²), determined by system voltage, maximum current, and installation distance.

3. Determine length and color.

- Red (positive), black (negative).

- Please provide the required length and color when ordering to avoid confusion.

4. Select insulation material and jacket.

- PVC: General use, economical.

- XLPE: High-temperature and oil-resistant, suitable for engine compartments.

- EPDM: Flexible and corrosion-resistant, suitable for marine and RV applications.

5. Identify the terminals and connection method

- Ring Terminals

- Alligator Clips (for Jumper Cables)

- Quick Plugs (such as Anderson Connectors)

6. Find a Custom Manufacturing Expert

- High-quality battery cables require not only high-quality materials but also reliable production and testing.

👉 Kaweei Custom Wiring Harness Factory

- 20+ Years of Experience in Wiring Harnesses and Cable Assemblies

- Providing customized services for battery cables, automotive wiring harnesses, and energy storage cables

- Supporting small batch and diversified customization

- Strictly adheres to IPC/WHMA-A-620 standards to ensure safety and reliability

If you need professional battery cable solutions, Kaweei's wire harness customization factory can provide you with high-quality, customized products to meet the various needs of automotive, marine, energy storage, and industrial equipment.