By quanyu lee

2025-04-14 00:30:55

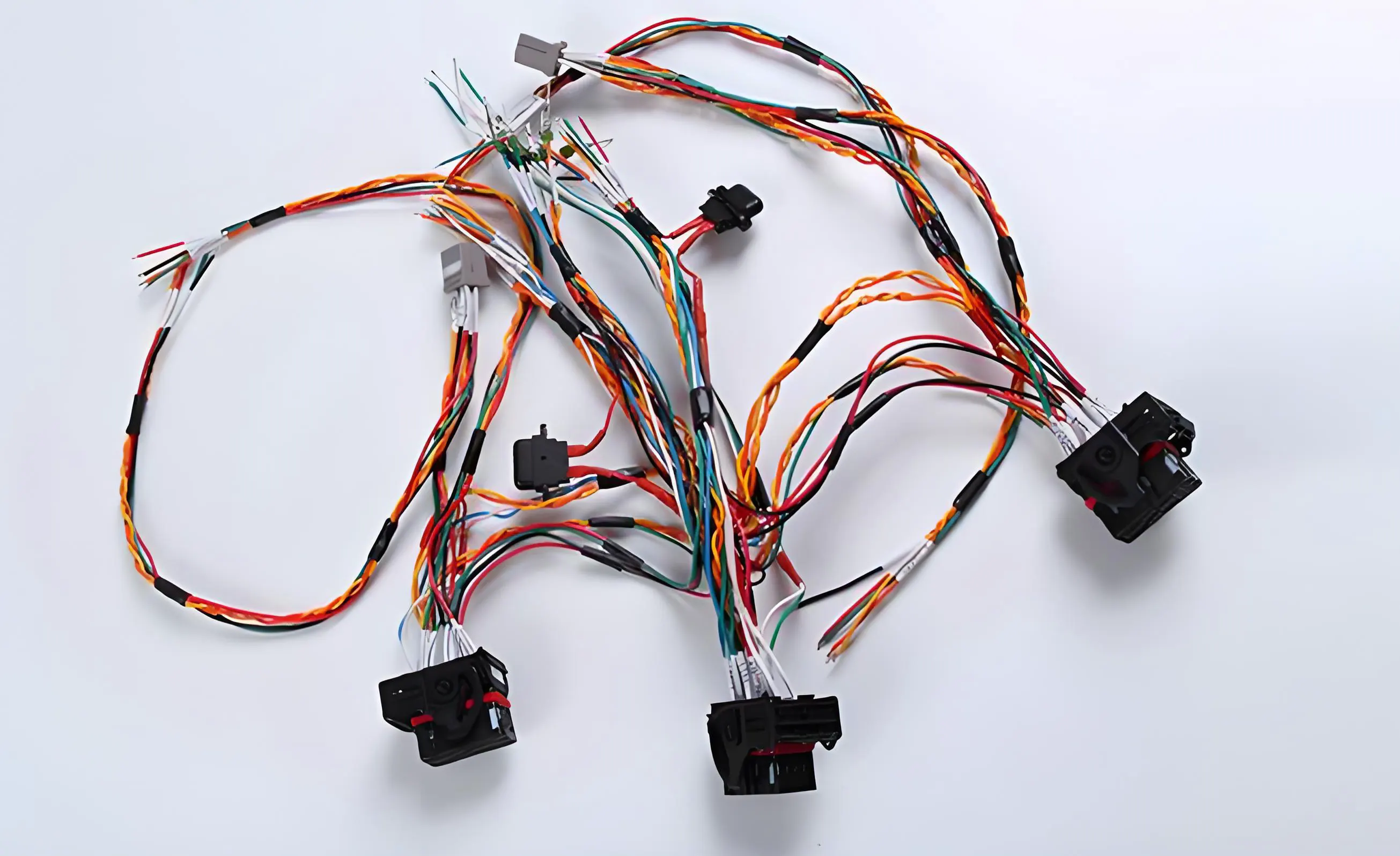

Custom Motorcycle Wiring Harness Guide

After motorcycle modifications, electrical upgrades, or prolonged use, the most easily overlooked yet most crucial part is the wiring harness. For many motorcycle owners and modification shops, custom motorcycle wiring harnesses not only solve aging problems but also make the vehicle's electrical system more stable and efficient, and can be used in conjunction with modifications to lights, electronic fuel injection systems, instruments, or high-voltage components.

This brand-new "Custom Motorcycle Wiring Harness Guide" will provide a comprehensive analysis of materials, structure, application, model differences, and fault protection, helping you quickly determine your needs before customization and avoid pitfalls.

1. What is a motorcycle wiring harness? Why is "customization" more important?

A motorcycle wiring harness is a system of wires pre-bundled according to circuit logic for transmitting power and signals. It consists of wires, terminals, connectors, protective tubes, tape, and fasteners.

However, universal wiring harnesses often have three problems:

- The wire gauge is incompatible with the load of new equipment (such as adding LED headlights or heated grips).

- The connector model is incompatible with the vehicle body interface.

- The original factory wiring is not suitable for off-road or modified routes.

Therefore, choosing a "custom motorcycle wiring harness" offers key advantages:

- Enhanced electrical load safety (no smoke, no short circuits)

- Connectors are fully compatible with the entire vehicle

- Easier installation

- Shock resistance can be upgraded according to specific scenarios

- Power requirements after vehicle modification can be fully met

For professional optimization, you can choose a custom wiring harness manufacturer like WIRE HARNESS ASSEMBLY to create dedicated wiring harnesses, improving overall vehicle stability.

2. Core Materials and Structure of Motorcycle Wiring Harnesses

1. Wire material: High-quality motorcycle wiring harnesses often use the following materials.

| Material | Features | Applicable scenarios |

| Oxygen-free copper (OFC) | High conductivity and low impedance | Ignition system and electronic fuel injection system main line |

| Tinned copper wire | More corrosion-resistant and moisture-resistant | Rainy season/Seaside/Off-road vehicle |

| PVC insulation layer | Standard wear-resistant protection | Ordinary streetcar |

| XLPE insulation layer | More resistant to high temperatures and gasoline | High-performance or off-road vehicles |

XLPE is often chosen for off-road vehicles and adventure vehicles (ADVs) because of its greater temperature variations and vibrations.

2. Cross-sectional area (wire diameter) determines "load capacity"

Common specifications for motorcycle cables: 0.5mm²–6mm²

Example of critical wiring:

- Starter motor wire: Up to 10–16 mm² (withstands instantaneous high current)

- Headlight wire: 1–1.5 mm²

- Signal wires (turn signals, instrument cluster): 0.5 mm²

When customizing wiring harnesses, the current must be recalculated based on your modified configuration; otherwise, it may lead to the following problems:

⚠️ Overheating wires

⚠️ Flickering headlights

⚠️ Difficulty starting

⚠️ Melting connectors

3. Connector (Terminal) Structure

The connector determines contact stability and is a watershed moment in wire harness quality.

Common Materials:

- Brass terminals (copper alloy 260): Standard models

- Tin-plated terminals: Anti-oxidation type

- Gold-plated terminals: Stable signal, suitable for high-end ECUs or sensors

Off-road vehicles and racing cars often require:

- Dustproof structure

- Prevents mud and sand from getting stuck

- Anti-vibration locking design

- Double-layer sealing rings

The high-voltage wiring harness for the new electric motorcycle also requires high-voltage-resistant orange HV connectors.

4. Wire Harness Protective Layer

Common Protection Methods:

- PET braided tubing: Lightweight and aesthetically pleasing

- PE corrugated tubing: Highest abrasion resistance

- Rubber sheath: Oil- and water-resistant

- Multi-layer wound tape: For use in confined spaces within the main frame tubes

Custom wiring harnesses for off-road vehicles typically include:

- Multi-layer protection

- Reinforced shock-resistant structure

- Increased fixing points (to prevent vibration and wear)

3. Comparison of wiring harnesses for different motorcycle models: road, off-road, and electric.

| project | Highway vehicle wiring harness | off-road vehicle wiring harness | Electric motorcycle wiring harness |

| Design focus | Stability + Comfort | Earthquake resistant + mud and sand prevention | High voltage insulation + EMC suppression |

| Wire structure | Ordinary PVC insulation | Thick insulation + tensile material | High-voltage orange cable + segmented management |

| connector | Standard dual-core terminal | Reinforced locking mechanism and waterproof structure | Precision high voltage connector |

| protection method | Lightweight sheath | Multiple layers of protection | Independent wiring for high and low voltage |

| point of failure | Insulation aging | Dust entering the connector | Electromagnetic interference, insulation damage |

4. Meaning of Motorcycle Wiring Harness Colors

Different brands may vary slightly, but the following are the mainstream industry standards.

| Color | Common uses | Remark |

| Red | Main power positive terminal | Battery → Ignition Lock |

| Black | Control the power supply / negative terminal | Some Japanese cars are positive. |

| Green | Chassis ground wire (negative terminal) | 90% of motorcycles are compatible |

| Blue | High beams / right turn | Different car models have different functions |

| White | Low beam/generator charging cable | White wire is commonly used for high-brightness lights |

| Yellow | Charging coil output | Connect to the regulator |

| Orange | Left turn signal | |

| Brown | Taillights, daytime running lights | |

| Black and white | Kill Switch | Cut off ignition |

| Pink | Sensor / Special control line | Commonly used for high-frequency signals |

When customizing wiring harnesses, the colors can be redesigned according to custom or international standards, making them particularly suitable for modified vehicles for repair and troubleshooting.

5. How to customize motorcycle wiring harnesses?

Step 1: Determine electrical requirements

- LED headlights installed?

- ECU upgraded?

- Navigation system, instrument cluster, and electronic throttle installed?

- Alternator or battery upgraded?

The more modifications are made, the more custom wiring harnesses are needed.

Step 2: Confirm the interface and wire gauge

- Current Calculation

- Terminal Matching

- ECU Socket Model

- Lamp Power

- Generator Output

Provide a reasonable wire diameter and structure.

Step 3: Set the wiring path

- Overheating

- Friction

- Short circuit

- Chassis scraping

A common mistake when modifying cars: tying the wiring harness near the exhaust pipe, causing it to melt directly in the heat.

Step 4: Seismic and Protective Design

- Increase anchoring points

- Use oil-resistant tubing

- Avoid exposed corners

- Apply waterproofing

Off-road and ADV vehicles especially need.

Step 5: Assembly by a professional factory

- Automated terminal crimping equipment

- Continuity tester (all pins)

- High voltage withstand test (EV models)

Specialized manufacturers such as WIRE HARNESS ASSEMBLY can provide end-to-end customization, including design, prototyping, to mass production.

6. Common Wiring Harness Problems and Troubleshooting Methods

1. Headlights flickering, possible causes:

- Insufficient wire diameter

- Connector oxidation

- Regulator load instability

2. Check for engine stall/failure to start:

- Is the black and white wire short-circuited?

- Is the ignition coil connector loose?

- Is the trigger coil open-circuited?

3. The battery is not charging; please check the following:

- Yellow/White Wire → Regulator

- Regulator → Battery Red and Black Wires

- Is Grounding Reliable?

4. Vibration from off-road vehicles causes frequent wire breakage. Solution:

- Use XLPE-insulated wire

- Double-layer protective tubing

- Reinforced fixing points

7. FAQ

1. Why must the wiring harness be custom-made when modifying a motorcycle?

Because the original motorcycle's wiring diameter, connectors, and load design are all based on the "factory configuration." Modifications increase power, the number of devices, and signal complexity, directly leading to safety hazards.

2. Are the connectors for imported motorcycles interchangeable?

Not entirely interchangeable, especially given the significant differences between Japanese, European, and American motorcycles. Custom wiring harnesses can be matched 1:1 to the original motorcycle connectors.

3. Are electric vehicle wiring harnesses more difficult to manufacture than those for gasoline vehicles?

Yes, because electric vehicles require high-voltage circuits (e.g., 48–300V), and insulation levels, temperature rise, and electromagnetic compatibility must be considered.

4. Is it worthwhile to replace the entire wiring harness when refurbishing an old motorcycle?

Absolutely. The most common problems with motorcycles over 20 years old are short circuits and oxidation.

5. What information is typically needed for a custom wiring harness?

- Motorcycle model

- Power requirements

- Application (Road/Off-road/Modified)

- Connector photos or samples

- Wiring length diagram

8. Summarize

The core of custom motorcycle wiring harnesses lies in reliable materials, matching wire diameters, accurate connectors, and adequate protection. Different motorcycle models (road, off-road, electric) have different requirements for shock resistance, waterproofing, temperature resistance, and electromagnetic compatibility. Properly selecting wires, connectors, and protective layers can significantly improve the overall stability and lifespan of the motorcycle. While color coding can help with quick identification, all customizations should still be based on the motorcycle's structure and actual modification needs. Professional wiring harness customization services (such as WIRE HARNESS ASSEMBLY) can ensure proper wiring routing, improved safety, and avoidance of common electrical faults, bringing greater reliability and maintainability to the motorcycle.