By quanyu lee

2025-01-09 01:30:34

Industrial Wiring Harness Innovation Guide: A Key Force in Promoting Smart Manufacturing and Sustainable Development

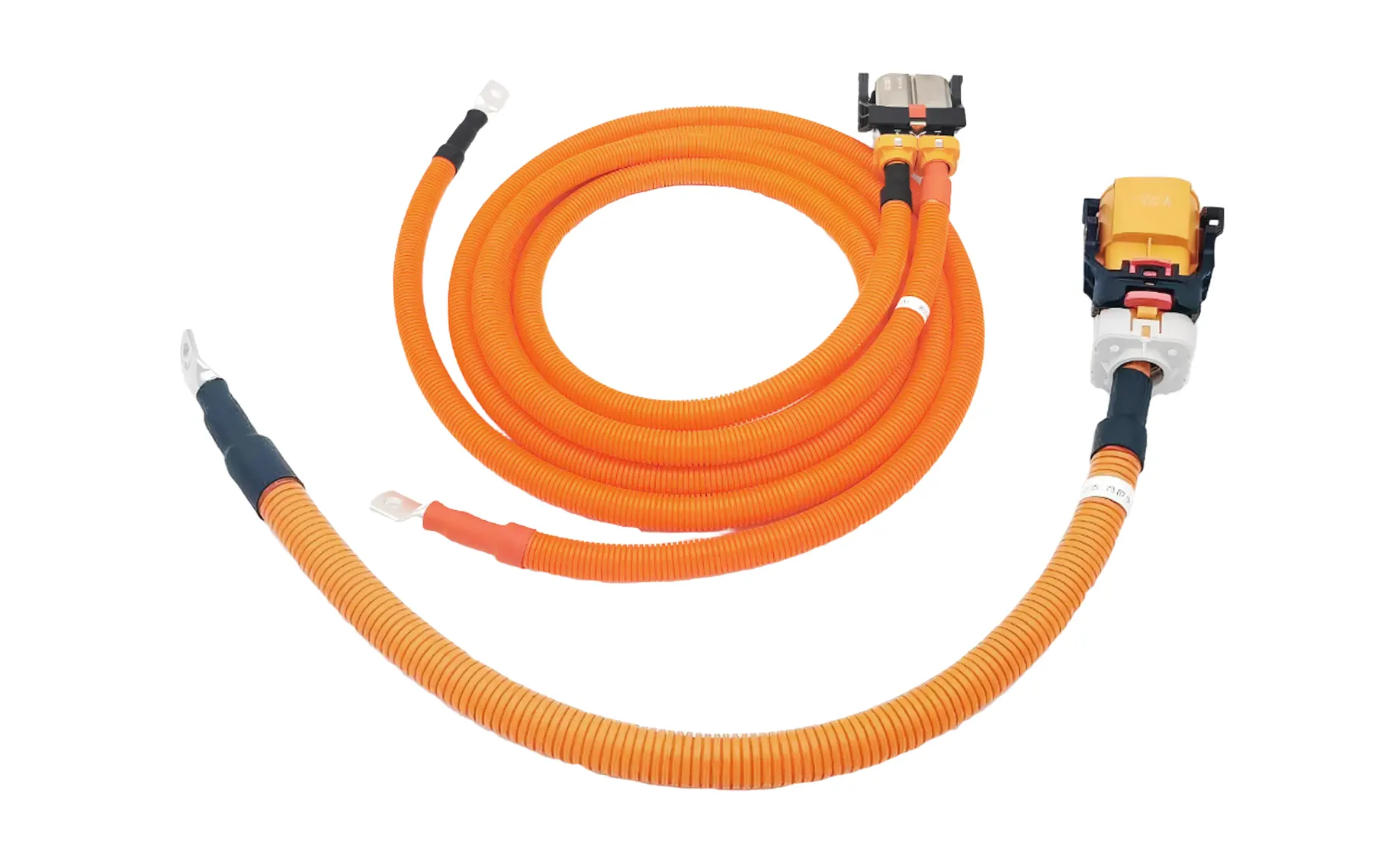

To know the direction of industrial wiring harness innovation, we must first know what an industrial wiring harness is. Industrial wiring harnesses can be divided into automotive wiring harnesses, electrical equipment wiring harnesses, industrial control wiring harnesses, display drive wiring harnesses, medical equipment wiring harnesses and energy field wiring harnesses according to their applications; they can be divided into power wiring harnesses, signal control wiring harnesses and data transmission wiring harnesses according to their functions; they can be divided into high temperature resistant wiring harnesses, lightweight wiring harnesses and protective wiring harnesses according to their material properties; they can be divided into parallel wiring harnesses, flat wiring harnesses and ring wiring harnesses according to their structural design.

Innovation direction of industrial wiring harness

With the rise of Industry 4.0 and smart manufacturing, industrial wiring harnesses are transforming from "passive connection" to "active perception." The following areas are key to innovation:

1. Smart Harness System

Modern industrial wiring harnesses are increasingly integrated with micro-sensors that monitor temperature, current, voltage, and vibration signals in real time. These "smart harnesses" can proactively identify potential failures and enhance predictive maintenance capabilities.

2. Environmentally Friendly and Sustainable Materials

To comply with international environmental standards such as RoHS and REACH, more and more manufacturers are adopting:

- Halogen-free flame-retardant materials;

- Recyclable insulation materials;

- Low-carbon copper conductors.

This not only reduces carbon emissions but also aligns with the global trend toward green manufacturing.

3. Highly Protective and Flexible Structure

Industrial environments are often subject to high voltage, dust, oil, and severe mechanical stress. To address this, the R&D team employed the following structural design elements:

- Multi-layer shielding (to combat EMI);

- Silicone sealing sheath (waterproof and dustproof up to IP68);

- Highly flexible drag chain cable (suitable for dynamic robotic applications).

The innovation direction of high-voltage wiring harnesses in the automotive field needs to start from the aspects of lightweight materials and high temperature resistance, which can reduce costs and improve performance.

Practical Applications of Industrial Wiring Harness Innovations

Innovative industrial wiring harnesses have been implemented in several key industries:

- Automated production lines: Modular wiring harness systems enable rapid installation and maintenance.

- Industrial robots: Highly flexible wiring harnesses accommodate high-speed motion and torque requirements.

- New energy equipment: High-voltage wiring harnesses ensure stable current transmission.

- Rail transportation and heavy machinery: Vibration- and corrosion-resistant wiring harnesses enhance operational safety.

Through these innovations, industrial wiring harnesses not only improve connection reliability but also lay the foundation for intelligent equipment operation. In terms of materials, aluminum wires are gradually replacing traditional copper wires. This change can reduce costs by more than 30% while reducing the weight of the wiring harness. New bio-based silicone materials can reduce carbon emissions by 50%, while micro-foam sheath technology achieves a 30% lightweight effect. These new materials not only have superior performance, but are also more environmentally friendly.

Future Trend: Intelligence and Customization Go Hand in Hand

Future innovations in industrial wiring harnesses will focus on the deep integration of intelligence and customization:

1. Data-driven Management

Future wiring harnesses will be equipped with RFID or QR code tags to enable full traceability of manufacturing, installation, and maintenance data, facilitating equipment asset management for businesses.

2. Visual Design and Simulation

Leveraging 3D modeling and simulation technology, wiring harness design will be more precise, reducing errors and waste in actual production.

3. Customized Solutions

More and more businesses are opting for professional wiring harness customization services to meet diverse equipment, environmental, and electrical requirements.

How to Choose a Quality Industrial Wiring Harness Supplier

A quality wiring harness manufacturer not only provides products but also systematic solutions.

When selecting a wiring harness, consider the following key points:

- Certification system: Whether the supplier has passed international quality certifications such as UL, ISO 9001, and IATF 16949.

- Material Source: Whether the supplier uses high-conductivity copper wire and high-temperature-resistant insulation.

- Testing Process: Whether the supplier undergoes 100% electrical performance and durability testing.

- Customization Capabilities: Whether the supplier can provide customized designs based on drawings or application requirements.

WIRE HARNESS ASSEMBLY has more than 15 years of experience in wire harness manufacturing, providing one-stop solutions from design, sampling, to mass production

FAQ: Frequently Asked Questions About Industrial Wiring Harnesses

Q1: What is the difference between industrial wiring harnesses and electronic wiring harnesses?

A1: Industrial wiring harnesses prioritize protection levels and reliability and are suitable for high-intensity industrial applications, while electronic wiring harnesses are primarily used in consumer electronics or home appliances.

Q2: Can smart wiring harnesses truly improve equipment efficiency?

A2: Yes. Smart wiring harnesses can monitor operating status in real time, prevent problems like short circuits and aging, and significantly reduce equipment downtime.

Q3: Can industrial wiring harnesses be customized?

A3: Yes. Professional manufacturers like WIRE HARNESS ASSEMBLY can customize wiring harness solutions based on drawings or samples.

Q4: How can I extend the lifespan of industrial wiring harnesses?

A4: Ensure regular inspections, avoid excessive bending, select materials with the appropriate protection level, and regularly clean connectors.

Summarize

Industrial wiring harnesses are not only the "connecting link" of electrical systems, but also an important infrastructure of the intelligent manufacturing ecosystem. With the development of AI, IoT, and green manufacturing, innovations in wiring harness technology will continue to drive the industrial system towards higher efficiency, smarter, and more sustainable directions. In short, in the process of innovation and development, industrial wiring harnesses should be improved in the direction of being cheaper, more environmentally friendly, and smarter.