By quanyu lee

2024-12-13 07:42:48

Industrial Wiring Harness Guide: From Basic Principles to Selection and Application

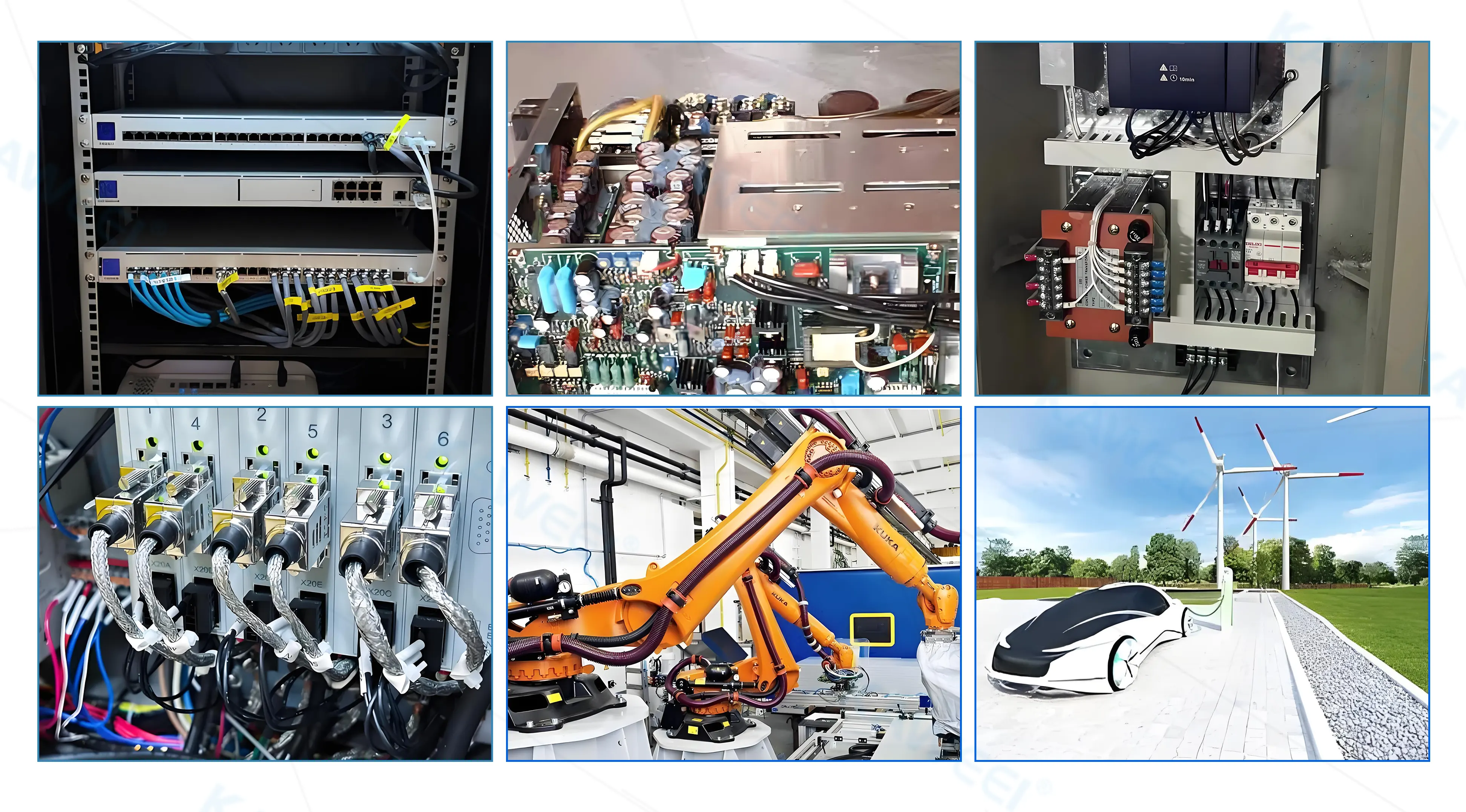

Industrial wiring harnesses have become a key component in connecting complex equipment systems. Whether in robotic arms, CNC machine tools, sensor control systems, or automated production lines, industrial wiring harnesses play the role of "neural networks." They integrate multiple wires, cables, and connectors into an efficient and compact system for transmitting power and signals. This integrated design not only improves assembly efficiency but also reduces wiring errors and maintenance costs. According to IPC standards, high-quality industrial wiring harnesses must meet multiple requirements, such as shock resistance, high temperature resistance, and anti-interference.

What is an industrial wiring harness?

An industrial wiring harness is an assembly used to connect device circuits and transmit signals and power. It typically consists of multiple wires, cables, connectors, sheathing, terminals, cable ties, and other components. Through standardized layout and packaging, it forms a stable and reliable electrical connection system, enabling safe and efficient communication and power supply between different modules.

Main Components of Industrial Wiring Harnesses

- Wire: Conducts electrical current or signals. Common materials include copper wire and tinned copper wire.

- Insulation: Prevents short circuits and electrical interference. Common materials include PVC, XLPE, TPE, and silicone.

- Connector: Connects various device interfaces and is key to wiring harness reliability.

- Sheath & Shielding: Provides mechanical protection and electromagnetic shielding.

- Terminal & Lug: Ensures a secure connection between wires and device ports.

These components are wired and assembled scientifically to enable industrial wiring harnesses to work stably in environments with high temperature, vibration, humidity, etc.

Classification of industrial wiring harnesses

- Power harness: Provides a power supply for industrial equipment, covering AC, DC, and power connections of different current specifications.

- Signal harness : Responsible for transmitting signal data such as position and temperature collected by sensors, commonly used in CNC systems and automation equipment.

- Control harness: Connects the control center and the execution unit, transmits switch commands or sensor signals, and is used in industrial robots, CNC machine tools, and other scenarios.

- Power harness: Designed for high-power devices, such as servo motors, spindles, etc., to ensure continuous power transmission.

- Data transmission harness: Used for signal upload and download, such as HDMI, USB, and other interface harnesses, commonly used in communication equipment and control systems.

Industrial Wiring Harness Manufacturing Process

The production of high-quality wiring harnesses requires strict process control. The manufacturing process typically includes the following steps:

1. Design and Drawing Confirmation

Use CAD or 3D wiring harness design software to plan wiring paths and lengths.

2. Wire Cutting and Stripping

Precision equipment ensures consistent wire lengths and damage-free stripping.

3. Terminal Crimping and Soldering

Automated crimping machines ensure consistent contact resistance.

4. Assembly and Cable Tie Fixing

Wires are bundled and labeled according to the design drawings.

5. Functional Testing and Inspection

Includes continuity testing, insulation testing, and pull tests.

Classification by application scenario

1. Industrial equipment harness

Used for wiring inside the cabinet, connecting UPS, PLC, inverter, and other equipment to ensure the operation of industrial machinery and automated production lines.

2. Automated equipment harness

For scenarios such as FAKRA/Ethernet, new energy high-voltage harness, etc., to support the needs of intelligent production lines.

3. Robot harness

Designed specifically for industrial robots, it must meet the requirements of high conductivity, anti-interference, and environmental resistance .

4. New energy field harness

Applied to new energy vehicles, wind power equipment, etc., emphasizing high reliability and anti-interference capabilities .

Industrial Wiring Harness Selection Guide

When purchasing or designing industrial wiring harnesses, engineers should consider the following factors:

1. Operating Environment

Is waterproof, oil-proof, or high-temperature resistant required? Outdoor equipment should be equipped with IP67 or higher protection.

2. Electrical Performance Requirements

Voltage, current, signal rate, and anti-interference performance.

3. Flexibility and Installation Space

Especially in robotics or dynamic motion equipment, the wiring harness's bend radius must meet requirements.

4. Certifications and Standards

Ensure that the wiring harness complies with international certifications such as ISO 9001, RoHS, and UL.

5. Maintainability

Select wiring harnesses with labeled, modular designs to facilitate future maintenance and replacement.

Maintenance and Question

Maintenance Recommendations:

- Regularly check the wiring harness for damage, deterioration, or looseness;

- Avoid excessive pulling or bending with a tight radius.

- Keep connectors clean to prevent oxidation.

- Use appropriate lubrication and protective materials.

Common problems and solutions:

| Question | Possible reasons | Suggested solutions |

| signal interference | Shielding layer broken or poor grounding | Check the shield connection and re-ground |

| The interface is loose | The plug is aging or not locked sufficiently | Replace the connector or re-crimp it |

| Wire harness heats up | Current overload | Optimize current distribution or replace with thicker wires |

Customized solutions for industrial wiring harnesses

WIRE HARNESS ASSEMBLY specializes in the design and customization of high-performance industrial wire harnesses, providing services including:

- Industrial Automation Wiring Harnesses

- Waterproof and High-Temperature Resistant Wiring Harnesses

- Control System Wiring Harnesses and Motor Cable Assemblies

- OEM/ODM Custom Wiring Harness Development

All products comply with ISO 9001, UL, and RoHS standards and pass rigorous testing to ensure stable operation in harsh industrial environments.

Industrial Wiring Harness Frequently Asked Questions (FAQ)

Q1: What's the difference between industrial wiring harnesses and ordinary household wiring harnesses?

A: Industrial wiring harnesses must operate in complex environments, such as high temperatures, vibration, humidity, and oil. Therefore, they require higher standards in material selection, shielding performance, and protection levels. Their reliability and lifespan are superior to those of ordinary household wiring harnesses.

Q2: What connectors are commonly used in industrial wiring harnesses?

A: Common connectors include M-series circular connectors, D-sub connectors, and brands such as Molex, TE, and JST. The choice depends on current, voltage, and installation space.

Q3: How can I determine if a wiring harness meets industry standards?

A: Check to see if it has UL certification, ISO 9001 certification, and complies with IPC/WHMA-A-620 assembly requirements.

Q4: What is the typical lifespan of industrial wiring harnesses?

A: Depending on the operating environment and load conditions, the lifespan is typically 5 to 10 years. However, high-end, flex-resistant materials (such as silicone or TPE) can extend this to over 15 years.

Q5: Can you customize industrial wire harnesses with different specifications and interfaces?

A: Of course. Wire Harness Assembly offers one-stop customization services, from schematic design and prototype development to mass production, to meet the needs of diverse industrial systems.

Q6: How can I improve the anti-interference performance of a wiring harness?

A: Double shielding, optimized grounding, and separate routing of signal and power cables can be used to improve electromagnetic interference (EMI) resistance.

Q7: What precautions should I take when maintaining or replacing a wiring harness?

A: Always power off the system before any maintenance. Use the original manufacturer's connectors and avoid substituting non-standard cables to prevent signal errors or short circuits.