By quanyu lee

2025-06-20 00:35:36

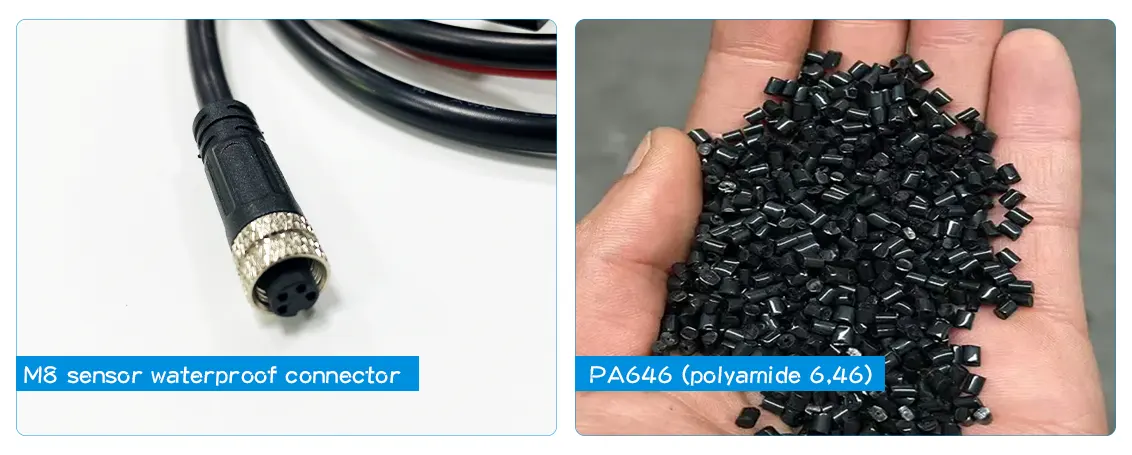

M8 sensor waterproof harness process analysis

In the field of industrial sensors, reliable data transmission is inseparable from precise waterproof connection solutions. This M8 sensor waterproof cable harness (with dust cover) is a key component of the sensor system. It combines high-quality materials and advanced production processes. This article will introduce the core materials, production technology, and quality control methods used in detail.

1. The inner mold material adopts a low-pressure injection molding process:

The inner mold of this M8 sensor waterproof harness is made of PA646 (polyamide 6,46) through low-pressure injection molding. PA646 is a high-performance nylon resin with excellent high-temperature resistance. It can work continuously at 150°C, which is very suitable for high-temperature sensor scenarios. Its mechanical strength is also excellent, with a tensile strength of 90MPa, which can withstand shock and vibration in industrial environments. At the same time, PA646 also has good chemical stability and is resistant to oil, solvents, and moisture, which can ensure the long-term and effective use of the connector.

This process can reduce internal stress and porosity, and achieve precise dimensional control of ±0.05mm and a smooth surface, laying the foundation for sealing performance.

2. The outer mold material is 35P PVC, which has the following key characteristics:

Excellent weather resistance: 35P PVC (containing 35 parts of plasticizer) can remain soft in the temperature range of -40℃ to 80℃, so it is not easy for the connector to fail due to high temperature, reducing the loss caused by downtime.

IP67 protection capability: With the dust cover, the PVC outer mold can completely block the entry of dust and can be immersed in 1 meter-deep water for 30 minutes without being affected. It is very suitable for use in humid or rainy environments and can reduce maintenance costs.

Flame retardant performance meets the standard: It meets the UL94 V-0 flame retardant standard and can be safely used in hazardous industrial areas.

3. Choose UL2586 wire

The conductor is made of tinned copper stranded wire (22AWG), with a resistance of ≤0.1Ω/m and good conductivity.

The insulation layer is a 3C PVC sheath, which is UL2586 certified and has the characteristics of oil resistance and wear resistance.

The rated voltage is 300V, which is suitable for low-voltage sensor circuits.

4. Detailed explanation of the production process of the M8 sensor waterproof wiring harness

- Wire stripping process: automated and precise operation, The stripping length accuracy of 22AWG wire is ±0.1mm through automated equipment, and the insulation layer damage rate is controlled to < 0.5% with real-time edge detection technology, effectively avoiding the risk of short circuits.

- Wire welding: High-frequency hot-press welding uses a welding machine with a temperature control accuracy of ±5℃, operating in the temperature range of 350℃~400℃; the tensile test is used to ensure that the tensile force of the solder joint is ≥5N, and the CCD detection technology is used to make the empty soldering/false soldering rate < 0.5%, ensuring the welding quality.

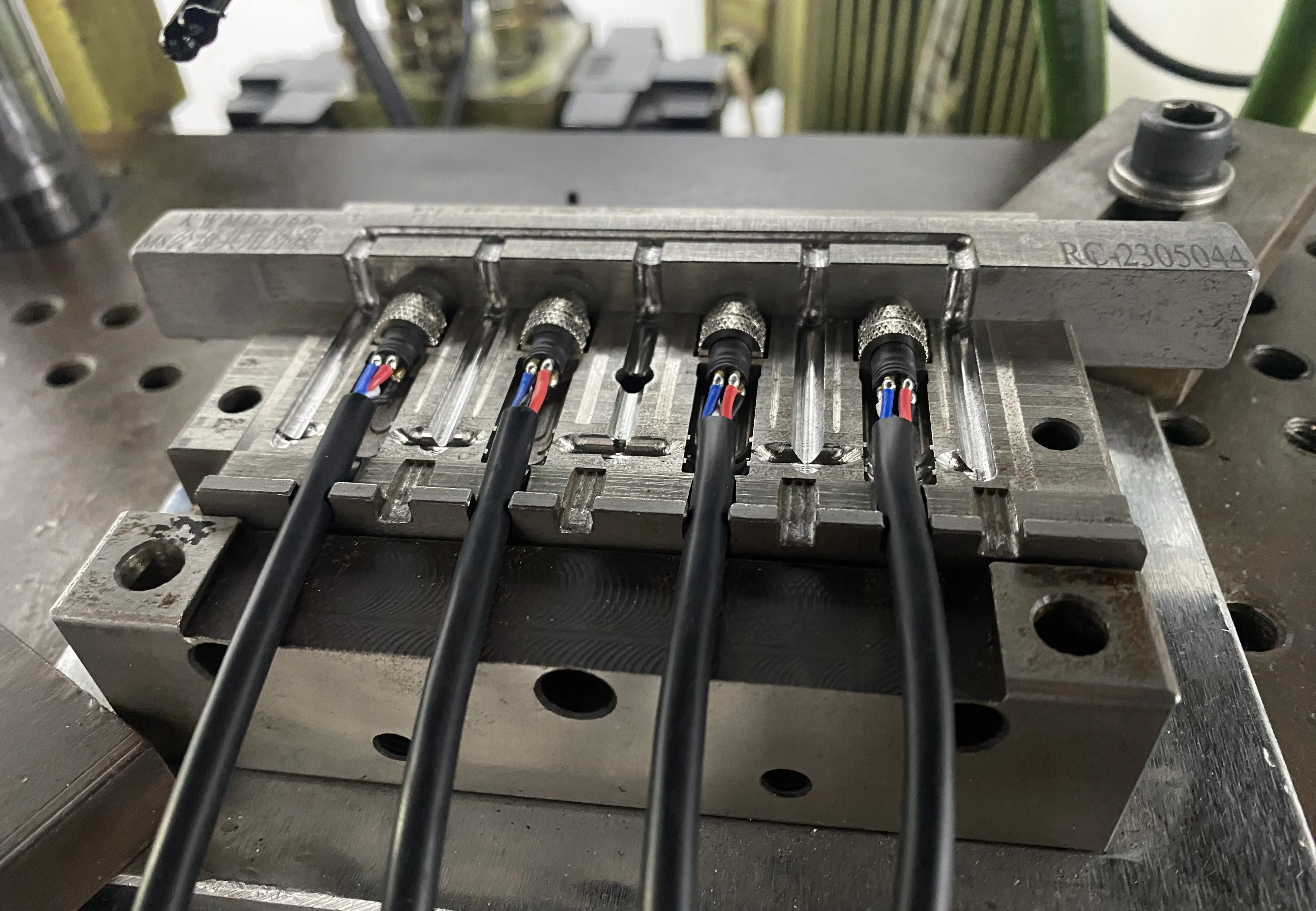

- Injection molding: secondary injection molding process

- Inner mold: PA646 material is used, and low-pressure injection molding is performed at 50~80 bar to ensure a close fit with the terminal;

- Outer mold: 35P PVC is used for secondary over-molding to form a seamless IP67 sealing structure;

- Production efficiency: single cycle 45 seconds, daily production capacity exceeds 10,000 pieces.

- Airtight test: Leak detection technology

- Air pressure test: maintain pressure at 100kPa for 30 seconds, pressure drop ≤5kPa;

- Water immersion verification: 1-meter deep immersion, infrared imaging to detect micro leaks.

- 100% functional continuity test: using a multi-channel continuity tester (resolution 100μΩ), contact resistance <50mΩ, insulation resistance >100MΩ (500V DC) is required to ensure that electrical performance meets the standards.

5. Application scenarios and technical advantages

The core use of this connector is to be suitable for scenarios such as industrial automation, smart sensors, and new energy equipment. It can stably transmit sensor data such as temperature, pressure, and vibration signal acquisition. The connector's anti-retraction design adopts a snap-on structure, and the plug-in and unplug life is ≥5000 times. It has been verified to be reliable through the anti-vibration loosening test with a test frequency of 50Hz and an amplitude of 2mm. In terms of environmental adaptability, it can operate at temperatures of -40℃~80℃ and has passed the ISO 9227 standard salt spray test of more than 1000 hours without corrosion. In terms of data transmission, the 22AWG wire supports 10Mbps signal transmission with a delay of < 1 ms, meeting real-time monitoring needs.

6. Why choose us

Because PA646 raw materials come from reliable sources, PVC complies with RoHS 2.0, the wire is UL certified, and ISO 9001:2015 system management is adopted. Key processes such as welding and injection molding have SPC process control. As a wire harness customization factory Kaweei, we can also adjust the molding structure, contact definition, wire length, etc. according to needs. From the precision inner mold of PA646 low-pressure injection molding to the protective design of 35P PVC outer mold, to the airtightness and conduction test of the whole process, every process of the M8 sensor waterproof wire harness focuses on the reliability requirements of industrial scenarios. If you need to know more technical details or sample testing, please contact us for customized solutions.