By quanyu lee

2025-04-08 08:43:09

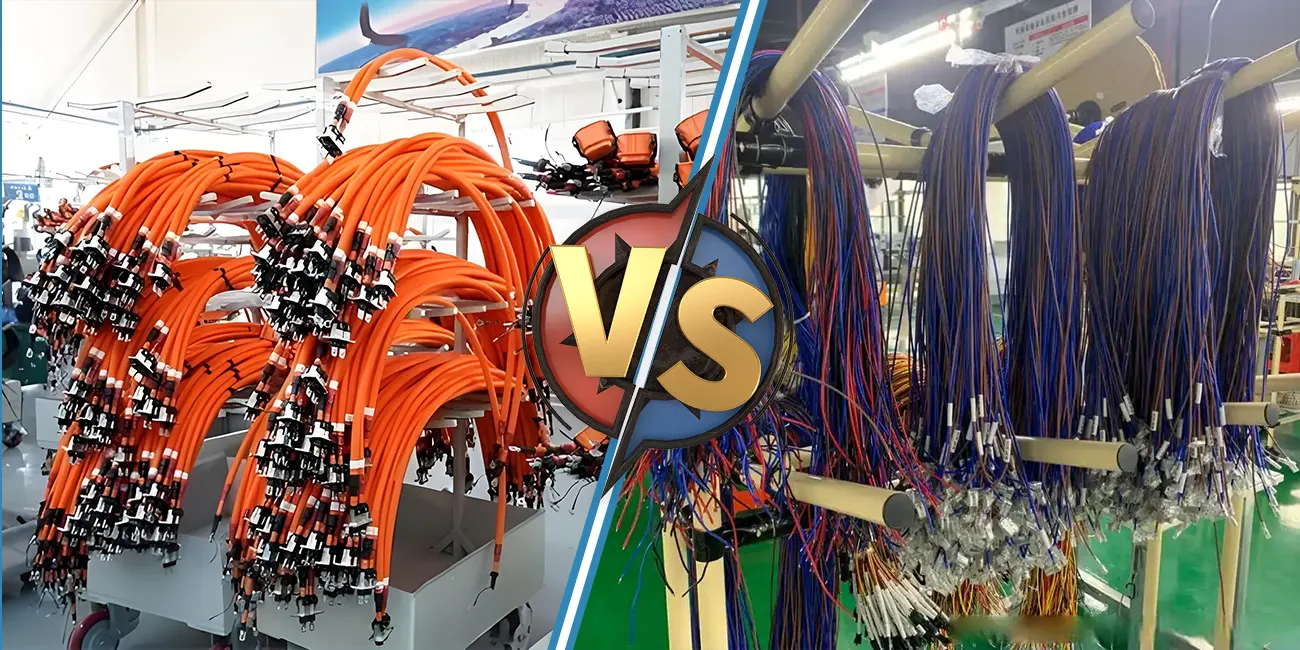

The difference between new energy wiring harnesses

Definition of New Energy Wiring Harness and Traditional Wiring Harness

- The new energy wiring harness integrates wires, cables, connectors, and other electrical components, designed specifically for electric vehicles (EVs) and hybrid electric vehicles (HEVs), covering the physical connections of the entire vehicle circuit.

- Traditional wiring harness is a basic component used to connect circuits in automobiles and electrical equipment. It is composed of multiple wires or cables integrated through binding, sleeves, and other methods, and equipped with connectors, insulation materials, and sheaths to achieve current and signal transmission. Its core goal is to provide stable physical connections for low-voltage electrical systems, widely used in scenarios such as traditional fuel vehicles and small equipment.

Materials for New Energy Wiring Harnesses and Traditional Wiring Harnesses

- New energy wiring harness materials: New energy wiring harnesses are made of high-temperature resistant (-40 ℃~150 ℃) and corrosion-resistant materials such as silicone and cross-linked polyethylene, while traditional wiring harnesses are mainly made of ordinary PVC.

- Traditional wiring harness materials: single or multiple copper core wires covered with insulation materials such as PVC.

Comparative Summary

| Dimension | New energy wiring harness | Traditional wiring harness |

| Voltage level | 300-1500V, required to withstand high voltage surges | 12-48V, low voltage environment |

| Current capability | 250-400A, high current heat dissipation design | Conventional current (<100A) |

| Material characteristics | Silicone/cross-linked polyethylene insulation+multi-layer shielding | PVC insulation, low cost |

| safety standards | IP67/IP6K9K protection+high voltage interlock | Fireproof and wear-resistant foundation protection |

From the above differences, it can be seen that new energy wiring harnesses have significantly higher adaptability to high-voltage environments, safety redundancy, and intelligent requirements than traditional wiring harnesses.

Functional and safety standards

Function Expansion

- New energy wiring harnesses not only provide power, but also need to transmit signals such as battery status and motor control, and integrate sensors and ECU linkage. Traditional wiring harnesses mainly rely on single power supply.

Security protection

- Protection level: New energy high-voltage wiring harnesses must meet IP67/IP6K9K waterproof and dustproof standards, while traditional wiring harnesses do not have such mandatory requirements.

- Security mechanism: New energy wiring harnesses are equipped with high voltage interlock (HVIL) to ensure safe power-off maintenance, while traditional wiring harnesses only need to meet basic standards such as fire prevention and wear resistance.

Layout and production process

Layout complexity

- The new energy wiring harness needs to be connected to dispersed components such as chassis batteries, front and rear axle motors, and wired over long distances across regions, while avoiding electromagnetic interference; The traditional wiring harness is fixed around the engine compartment layout.

Process requirements

- New energy wiring harnesses have strict requirements for crimping processes (such as battery pack voltage collection wiring harnesses), sealing (oxidation resistance), and mechanical protection (vibration/impact resistance), and must comply with zero defect standards such as IPC620

New energy wiring harnesses integrate power, data, and intelligent control signal transmission, while traditional wiring harnesses only rely on basic power supply.

In short, new energy wiring harnesses are centered around high voltage, lightweight, and intelligence, providing high safety and high reliability connection solutions for electric and intelligent vehicles.