By quanyu lee

2025-10-15 10:47:39

XLR Cable Guide: From Construction to Sound Quality

XLR cables are commonly found in recording studios, concert halls, and lighting consoles. In the world of professional audio, they're synonymous with quality and stability. However, many people still understand XLR simply as being more expensive than regular audio cables. In reality, the decades-long legacy of XLR cables stems from a complex combination of factors, including signal physics, shielding techniques, material engineering, and system compatibility. This article offers a fresh perspective on XLR cables, explaining why they've become a vital component of professional audio systems.

1. What is an XLR cable?

XLR cable is mainly used to transmit balanced audio signals. It is a connection cable designed specifically for professional audio equipment. It uses a 3-pin (XLR) interface and is widely used in microphones, mixers, amplifiers, and other equipment. The name of the XLR cable comes from the product iteration history of its inventor, Cannon Electric. X represents the original model name "Cannon X" series, which is the basic version of the connector. L comes from "Latch" (locking device). The "Cannon XL" series added a spring lock structure to ensure a stable connection and prevent it from falling off. R stands for "Rubber".In 1955, Cannon added synthetic rubber insulation around the connector contacts to improve resistance to wear and environmental interference, eventually forming the complete "XLR" naming system. XLR connectors have become the industry standard interface in the professional audio field with their balanced transmission technology, interference cancellation through the hot end, cold end, and ground pins, spring lock design, and durable materials.

XLR cables:

- Maintain low noise over long transmission distances;

- Prevent ground loop interference.

- Provide a secure, strong connection.

2. Structure and Signal Principle of XLR Cable

The design of an XLR cable may seem simple, but it incorporates the scientific principles of signal symmetry and interference resistance. Its core structure is as follows:

Conductor

- Typically, high-purity oxygen-free copper (OFC) or silver-plated copper is used to ensure low impedance and high conductivity.

- For audio, conductor purity directly affects dynamic range and sound reproduction.

Insulation

- Common materials: Polyethylene (PE), Polyvinyl Chloride (PVC), Teflon (PTFE).

- Function: Prevents short circuits between positive and negative signals while maintaining constant impedance.

Shielding

- Dual-layer construction: braided copper mesh + aluminum foil.

- Shields against external electromagnetic interference (EMI) and radio frequency interference (RFI).

- High-quality shielding ensures clear signal transmission over a 100-meter XLR cable.

Outer Jacket

- Made of flexible, wear-resistant materials, such as thermoplastic elastomer (TPE).

- Suitable for repeated winding and unwinding, and for high-temperature, high-humidity environments.

XLR cable has three wires, The balanced signal principle is explained:

Pin 1: Ground (Shield)

Pin 2: Positive Signal (Hot)

Pin 3: Negative Signal (Cold)

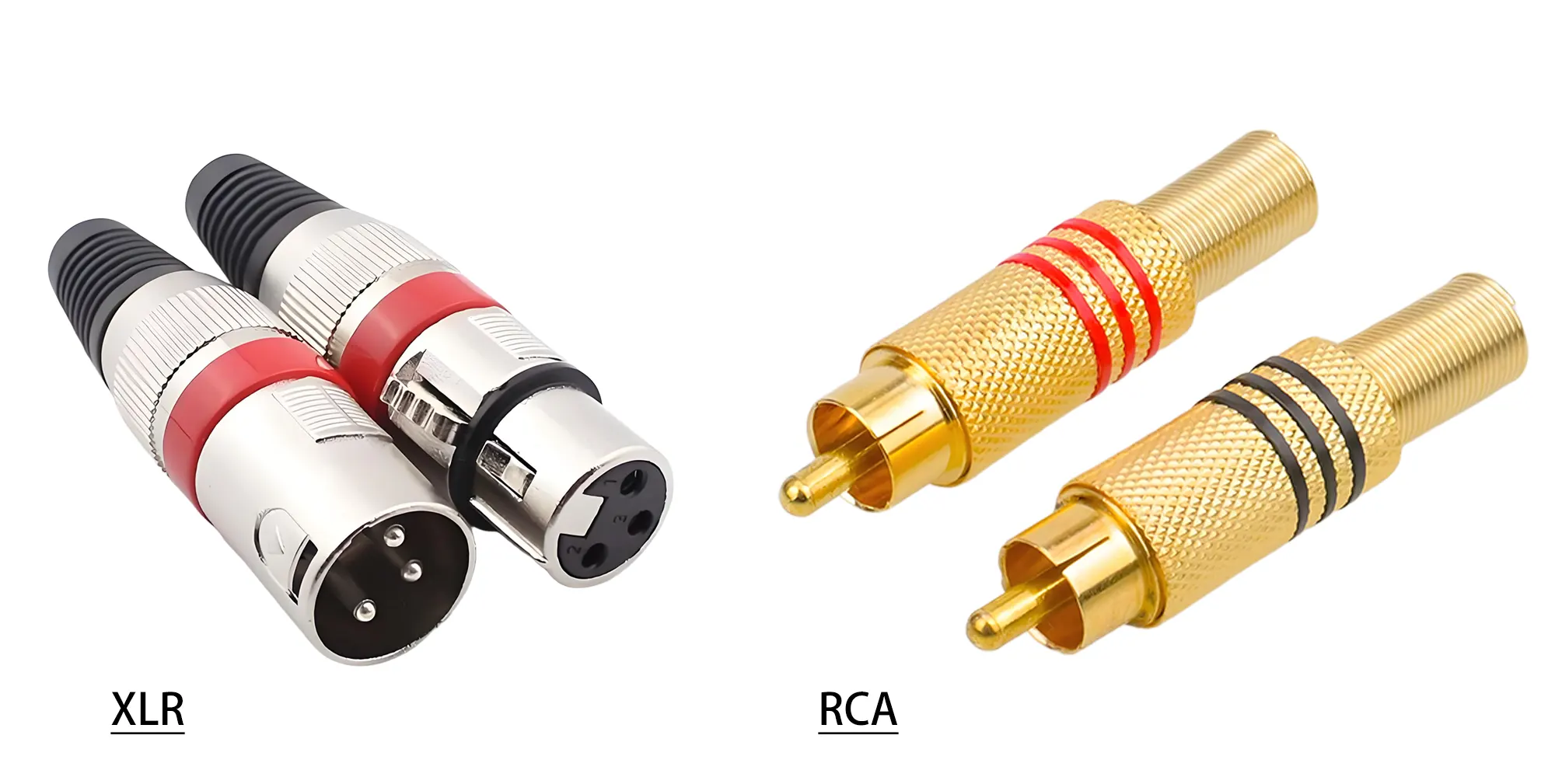

When positive and negative signals are transmitted with opposite polarity, external noise is canceled out at the receiving end, achieving "common mode rejection (CMR)", which is the core reason why it is superior to ordinary unbalanced lines (such as RCA).

3. Main Types and Differences of XLR Cables

| Type | Features | Typical uses |

| 3-pin XLR cable | The most common type, used for balanced audio transmission | Microphone, mixer, amplifier |

| 5-pin XLR cable | Support DMX512 lighting control or stereo signal | Stage lighting system |

| XLR to TRS (6.35mm) cable | Achieve balanced interface compatibility | Connecting the recording interface to the mixing console |

| XLR to bare wire cable | One end can be freely wired | Engineering installation, DIY, test bench wiring |

| Digital AES/EBU XLR cable | 110Ω impedance, dedicated to digital audio signals | Professional broadcasting and recording equipment |

Many people confuse "DMX cable" and "audio XLR cable". Although the interfaces look similar, their impedances are different (DMX is about 120Ω). Mixing them will cause signal attenuation or control delay.

4. Application fields of XLR cables

XLR connectors are no longer just for recording studios; they're used in nearly every demanding signal scenario:

- Professional audio systems: connecting microphones, mixers, amplifiers, and monitor speakers;

- Broadcast and television systems: high-fidelity recording and signal distribution;

- Stage and lighting control: DMX512 protocol standard interface;

- Industrial and communications: interference-resistant control signal transmission;

- Aerospace and medical: used for precision sensor data transmission, favored for its reliable locking structure.

5. XLR vs. RCA Sound Quality Comparison

XLR Advantages:

- Balanced transmission, strong anti-interference capability;

- Excellent impedance matching, lower signal line loss;

- Reliable connector locking mechanism, low contact resistance

Disadvantages of RCA:

- Unbalanced signal, susceptible to noise interference;

- Transmission distance should not exceed 5 meters.

- Connectors can become loose, causing background noise or distortion.

Therefore, in long-distance, high-dynamic audio systems, XLR audio quality is purer and the background is quieter.

6. Can XLR be used as speaker cables?

Direct use is not recommended. Although XLR looks sturdy, it is designed for low-current audio signals, while speaker wire needs to carry high power output.

Using XLR cables to connect passive speakers may result in:

- Excessive current causing cable heating;

- Impedance mismatch;

- Loss of sound quality or damage to the device.

However, if you have powered speakers (with built-in amplifiers), XLR cables are ideal, allowing for a very low-noise signal input.

7. Comparison between XLR and Jack (6.35mm)

| Comparative item | XLR cable | Jack (TRS) cable |

| Connection security | With a lock structure, not easy to loosen | Plug-in connection, easy to slip off |

| Anti-interference ability | Balanced transmission is better | Slightly weak, easily affected by external noise |

| Durability | Metal shell, high bending resistance | Mainly plastic shell, short lifespan |

| Application scope | Professional stage, recording studio, broadcasting | Semi-professional or consumer equipment |

Conclusion: In professional audio scenarios, XLR is a more reliable and more "engineering-grade" solution.

8. XLR Evolution and Digital Fusion

With the advancement of digital audio technology, the traditional XLR connector has also been continuously upgraded:

- Digital AES/EBU standard: Using XLR to transmit digital signals, replacing coaxial connectors.

- Neutrik EtherCON: Integrating an RJ45 network connector into an XLR form factor, for use in network audio systems like Dante.

- Eco-friendly and lightweight materials: Next-generation TPE jackets reduce plastic use, improving flexibility and sustainability.

The XLR cable of the future will not only be a “signal channel”, but also a fusion carrier of digitalization and reliability.

9. FAQ: Advantages of Custom XLR Cables

Q1. What are the advantages of custom XLR cables or audio harnesses?

A1: Kaweei has many years of professional experience, providing integrated services from design, prototyping, production, and testing. We specialize in customizing XLR cable harnesses with varying lengths, connector types, and shielding structures to ensure signal stability and structural durability.

Q2.What is Kaweei's competitive advantage compared to other suppliers?

A2: High-quality materials: Utilize UL-certified cables and connectors from international brands such as Neutrik and Amphenol.

- Strict quality control: Certified to ISO9001 and RoHS standards.

- Flexible delivery: Supports small-batch trial production and rapid prototyping.

- Comprehensive technical support: Provides design consultation and sample testing services.

Q3: Where can I learn more about our custom wire harness services?

A3: You can visit: WIRE HARNESS ASSEMBLY Custom Cable Solutions

Q4: What are some tips for choosing XLR cables?

A4: Give priority to cables with shielding layers and nylon braided outer sheaths to ensure signal stability; select male/female connectors according to the device interface and pay attention to cable impedance matching.

10. Conclusion

As the gold standard for professional audio transmission, XLR cables continue to play an irreplaceable role in recording, performance, and broadcasting thanks to their balanced design, interference resistance, and industrial-grade durability. Their standardized interface and modular structure ensure signal purity while adapting to deployment requirements in complex environments. With the evolution of digital audio technology, XLR cables maintain their core position in analog signal transmission and are gradually expanding towards digital compatibility (such as Dante networking). In the future, while maintaining their traditional advantages, innovations in lightweighting and intelligent technology may become new directions for their development.