By quanyu lee

2025-09-25 15:33:46

What is a Wire Harness? Application and Structure Analysis

As modern electronic and industrial systems become more complex, the wire harness has grown into an indispensable component for safe, reliable wiring and signal/power distribution. WIRE HARNESS ASSEMBLY, a custom wire-harness site under Kaweei, provides tailored harness solutions across automotive, industrial, medical, and communications fields. This article explains what a wire harness is, how it’s built, where it’s used, and why it matters.

1. What is a wire harness?

A wire harness (also called a wiring harness or cable assembly) is an organized bundle of wires, cables, and associated components assembled to transmit power and signals between devices or modules. Its main purposes are to keep wiring tidy, protect conductors from mechanical and environmental damage, simplify installation and maintenance, and improve system reliability. For the safety of machine wiring and electrical equipment, standards such as IEC 60204-1 guide wiring practices and requirements.

2. Basic structure of a wire harness

A typical wire harness comprises several layers and elements:

Conductor (wire/core): the metallic element (usually copper or aluminum) that carries current or signals.

Insulation: polymer or other insulating materials surrounding conductors to prevent short circuits and provide mechanical protection.

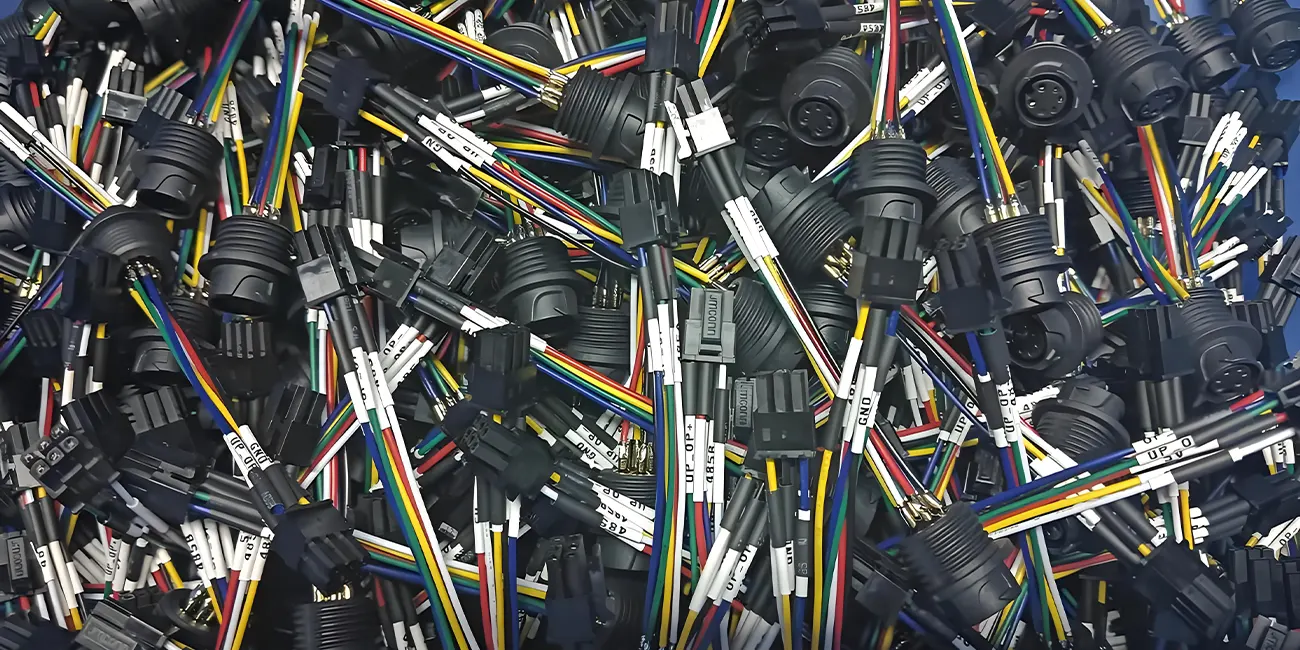

Connectors: plug-and-socket components that allow modules or devices to be joined or disconnected safely.

Sheath / protective outer layer: a jacket or conduit that protects from abrasion, chemicals, moisture, and heat.

Shielding (if required): metal braids or foil to reduce electromagnetic interference (EMI).

Material selection (insulation type, jacketing, plating on terminals, seal materials) is chosen to match operating temperature, chemical exposure, flame retardant, and environmental sealing needs. Appliance and equipment wiring practices are often tested/certified against UL standards such as UL’s Appliance Wiring Material (UL 758) and related UL services.

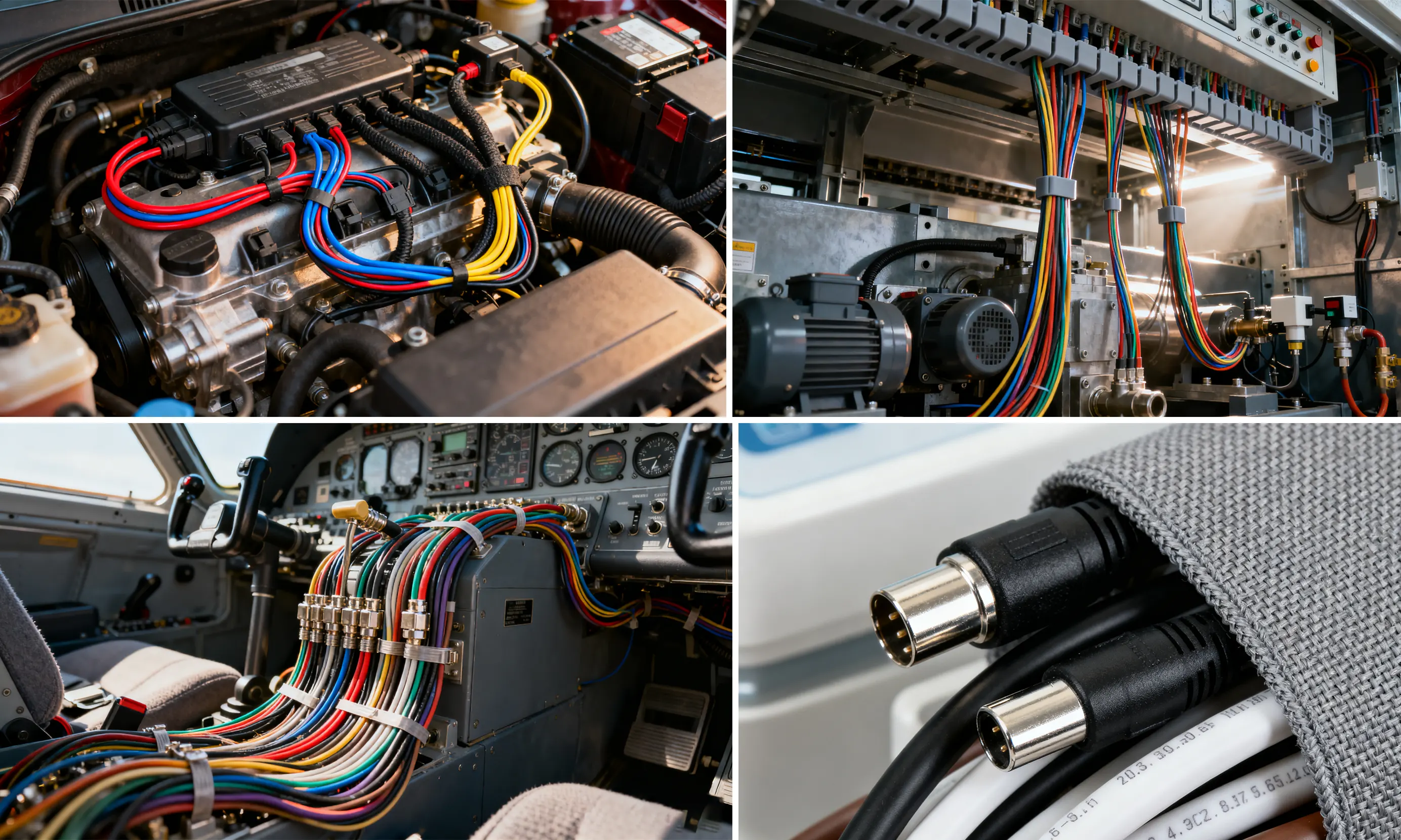

3. Application fields for wire harnesses

Wire harnesses are used widely across industries, including:

Automotive: engine harnesses, lighting, airbags, infotainment, and power distribution.

Industrial automation: factory machinery, robotic cells, and control cabinets.

Medical devices: imaging machines, monitors, and diagnostic equipment (where reliability and biocompatible materials may be required).

Telecommunications & consumer electronics: base stations, servers, appliances.

Defense & aerospace (when meeting military specs): ruggedized harnesses for harsh environments (see MIL-SPEC repositories).

4. Core components of wiring harness assembly

The core components of a wiring harness assembly consist of multiple key parts that collectively ensure its stable operation and functional realization. Among them, wires and cables serve as the basic transmission carriers. They are customized into single-core or multi-core conductor structures according to actual current and signal requirements, adapting to transmission needs in different scenarios. Terminals, as end connection accessories, are processed through crimping or welding techniques, effectively ensuring tight contact between wires and connectors or chassis, thereby guaranteeing stable transmission of current and signals. Connectors, as modular docking interfaces, come in various forms such as round, rectangular, panel-mounted, and sealed automotive types suitable for special environments, flexibly meeting the docking needs between different devices. Protective layers and shielding components are crucial, including sheaths, braids, foils, sleeves, and gaskets. They not only provide good protection for the internal structure but also effectively control electromagnetic interference (EMI) to prevent external interference from affecting the normal operation of the wiring harness. In addition, cable ties and wiring hardware, including cable ties, clamps, conduits, and channels, are mainly used to organize and secure the wiring harness, ensuring it remains neat and orderly during installation and use, and preventing malfunctions caused by looseness or other issues.

5. How harness components work together

The conductor carries the electrical signal; the insulation protects it; terminals and connectors form reliable electrical and mechanical joints; shielding prevents interference; and protective layers plus routing hardware protect the whole assembly from mechanical strain, e,e and abrasion. Well-designed harnesses simplify assembly, reduce installation time, and facilitate troubleshooting, all of which contribute to system uptime and safety.

6. What happens if a wire harness fails?

Failure modes and consequences include:

Intermittent or lost signals cause the malfunction of sensors, controllers, or safety systems.

Short circuits that can blow fuses or cause component damage.

Overheating and fire risk in severe cases when insulation is compromised.

System downtime and costly repairs — in vehicles, this can mean non-start conditions or impaired safety functions.

Because harness failures can have serious safety and operational impacts, routine inspection and timely replacement are important.

7. How much does it cost to replace a wire harness?

Replacement cost depends heavily on complexity, application, and whether the harness is a standard off-the-shelf part or a fully custom assembly. Factors that affect price include harness length, number of conductors, connectors and seals, required certifications, and production volume. For simple consumer/automotive harnesses, costs can be relatively low; for specialized medical, industrial, or military custom harnesses, costs rise substantially due to stricter material requirements and testing.

8. What is the difference between a cable and a wire harness?

Cable: Typically refers to a single electrical component (single-core or multi-core) designed for transmitting electricity or signals.

Harness: An organized combination of multiple wires/cables, connectors, and protective hardware, designed to be integrated into a larger system. In short, a harness is a system-level, organized component; whereas a cable is a single transmission medium.

9. Frequently Asked Questions - Common Issues Regarding Wiring Harnesses

Q1: Are wire harnesses and cable assemblies the same?

Answer: They have similarities, but "cable assembly" usually refers to a specific cable with terminations; "wiring harness" emphasizes a bundled, system-installed wiring component with wiring hardware and multiple branches.

Q2: How long do wire harnesses last?

A: Under normal conditions and with proper materials, many harnesses last 10+ years; lifespan depends on environment (temperature cycles, vibration, chemical exposure) and material selection.

Q3: Can I repair a damaged harness, or should I replace it?

A: Minor localized damage (a single broken conductor or terminal) can sometimes be repaired if done to proper standards; extensive damage, corrosion, or compromised sealing usually means replacement is safer.

Q4: What certifications should I request for critical applications?

A: For safety and market access, request relevant certifications: UL testing/certification where applicable, RoHS compliance for restricted substances in the EU, and military specifications (MIL-SPEC) for defense use.

Q5: How do you choose insulation or jacket materials?

A: Choose based on operating temperature range, flame rating, chemical exposure, flexibility requirements, and whether EMI shielding or waterproofing is needed.

Q6: Do wire harnesses require EMI shielding?

A: If the system handles sensitive signals or operates near strong electromagnetic sources, shielding is recommended to preserve signal integrity.

Q7: Can you produce small-batch custom harnesses?

A: Yes — many custom manufacturers (including specialist sites like WIRE HARNESS ASSEMBLY under Kaweei) offer prototyping and small-batch production as well as full-scale runs.

10. Conclusion

A wire harness is the organized backbone of electrical systems — it secures power and signals, protects conductors, eases installation, and safeguards reliability. For industries from automotive to medical and industrial automation, correct harness design, material selection, and compliance with standards (such as IEC 60204-1, UL testing/programs, and RoHS restrictions) are key to safe, long-lasting systems.