By quanyu lee

2024-12-13 03:20:16

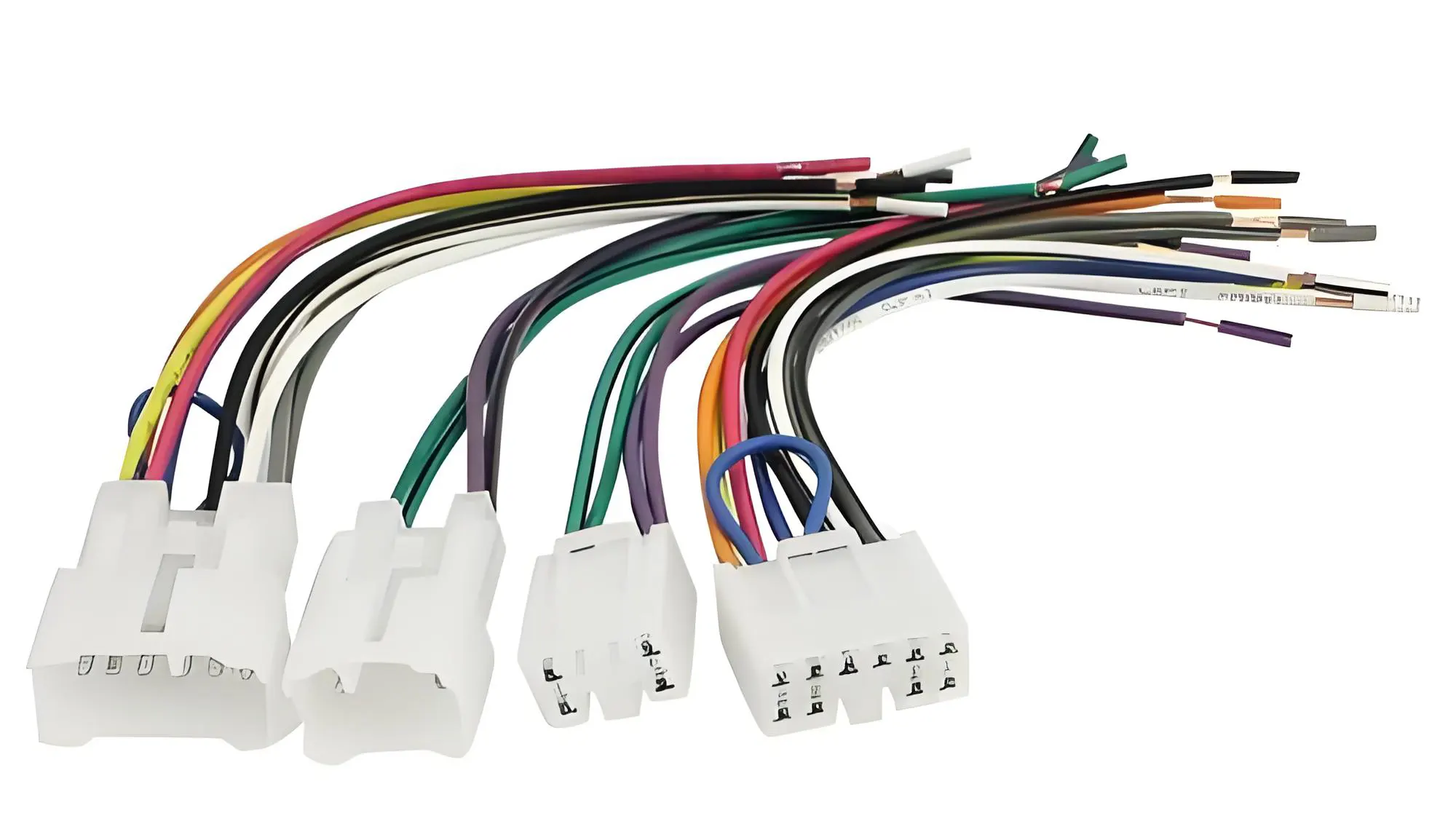

Electric vehicle wire harness

The wiring harness of electric vehicles is an integrated cable network that connects high-voltage batteries, motors, electronic control systems and on-board equipment. It is composed of high-voltage cables, low-voltage wires, connectors, shielding layers and protective materials. It is responsible for power transmission, signal control and data communication functions. It is the "blood vessels and nerves" of the power and intelligent system of electric vehicles.

Car dashboard wiring harness core function analysis table

Function classification |

Detailed description |

Related technical implementation and standards |

| Signal transmission | Transmits real-time vehicle status data such as vehicle speed, rotation speed, fuel level, etc. to the instrument display screen, supports visual feedback of driving information, and transmits combination switch commands (such as lighting and air conditioning control signals) to the actuator. | Use multi-core copper wire to ensure signal integrity and follow the CAN bus protocol to ensure communication stability. |

| Power distribution | Provide 12V/24V power to dashboard devices (central control screen, electronic accelerator pedal, etc.) through the cockpit power distributor, support parallel power supply for multiple devices, and be compatible with new functional modules of the smart cockpit. | The cross-sectional area of low-voltage conductors is 0.35-2.5mm², and the balanced current carrying capacity and lightweight standardized grounding design reduce line voltage drop. |

| Safety protection | Flame-retardant corrugated tube wraps the wire to prevent short circuit or friction fire. The wire harness fixing bracket reduces vibration interference and improves durability. | The material temperature resistance range covers -40℃~150℃, and the grounding point is rust-proofed to optimize grounding reliability. |

| Extended compatibility | Reserved interfaces support upgrade and expansion of smart cockpit equipment (such as voice control, HUD head-up display) | The connector adopts a modular design to support quick plug-in and expansion . |

The core components and characteristics of electric vehicle wiring harnesses

High-voltage wiring harness system (300V~800V)

Material: High-temperature resistant silicone or cross-linked polyethylene (XLPE) insulation layer, copper core cross-sectional area of 25-95mm², supports high current (200A+) transmission.

Shielding: Double-layer aluminum foil + braided copper mesh shielding to reduce the impact of electromagnetic interference (EMI) on low-voltage signals.

Protection: Meets IP67/IP69 waterproof and dustproof levels, suitable for splashing and wading conditions at the bottom of the battery pack.

Low-voltage wiring harness and communication wiring harness

Low-voltage wiring harness: connects the body controller and sensor (12V/24V), using thin-walled wires (0.35-2.5mm²) to reduce weight.

Communication wiring harness: high-speed CAN FD, Ethernet (1000BASE-T1) cables, supporting autonomous driving and OTA upgrade data transmission.