By quanyu lee

2025-06-20 03:59:44

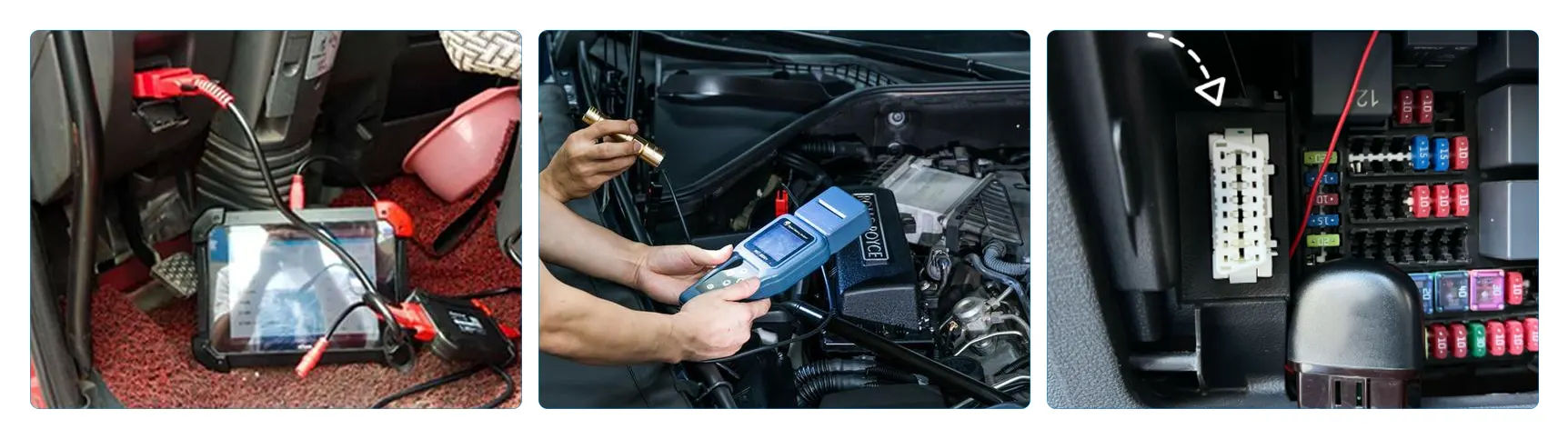

Customizable high performance OBD2 cables for vehicle

This vehicle OBD2 cables adopts a 16-pin OBD male/female design and consists of a PIN to PIN welding process and a Molex connector; It is a wiring harness solution specially customized for automotive diagnostic systems, which can ensure reliable data transmission and electrical connection; It is suitable for professional scenarios such as OBD-II diagnostic equipment, onboard diagnostic systems, and automotive electronic test platforms.

Core technical parameters

| product specifications | Detailed parameters |

| OBD interface type | 16-pin male/female connector, compliant with SAE J1962 standard. |

| Welding process | High-precision PIN to PIN point-to-point welding, welding point vibration resistance ≥2.5~4G. |

| Shell material | ABS engineering plastic (UL94 V-0 flame retardant grade), ultrasonic welding seal. |

| Protection level | IP67-rated for dust and water resistance and -40°C to +125°C operating temperature range. |

| Wire specifications |

UL2464 22AWG 2C (signal line) + 24AWG 9C (power line)+24AWG 1P (shielded wire) UL2464 22AWG 1P (main line) + 22AWG 3C (auxiliary line) |

| Terminal / Plastic Shell | Molex 51115-1601 (plastic shell) + Molex 50420-8000 (terminal), in compliance with USCAR-2 standards. |

| signal transmission | Supports multiple protocols such as CAN/LIN/KWP2000, with a transmission rate of ≥5Mbps. |

| Customized services | Customizable length, color coding, logo printing, and wiring harness branching structure. |

Process advantages

Precision welding technology: semi-automatic welding process is adopted, the diameter error of the welding spot is ≤0.05mm, ensuring extremely low contact resistance (<1mΩ).

Ultrasonic sealing process: the shell is made of ABS material through 20kHz ultrasonic welding to form a molecular-level bond, and the airtight performance reaches 10kPa/min.

Error-proof design: the OBD interface adopts an asymmetric keyway design to 100% prevent mis-insertion; the terminal adopts a polarization design to ensure the only correct insertion direction.

Stress release structure: the joint between the wire and the connector adopts a tapered stress buffer design, and the bending resistance is >10,000 times.

Material properties

| Part | Material properties |

| Wire | UL2464 standard oil-resistant PVC insulation layer, tinned copper conductor (purity ≥99.97%), capacitance ≤50pF/m |

| Terminal | Phosphor bronze substrate + 0.8μm gold plating layer, insertion and extraction force 1.5-3.5N, contact resistance <10mΩ |

| Plastic shell | Glass fiber reinforced nylon 66, chemical resistant (gasoline, oil, antifreeze), flame retardant grade UL94 V-0 |

| Seals | EPDM, Shore hardness 70±5A, aging resistance life >10 years |

Application scenarios

This vehicle OBD2 cables is suitable for scenarios such as car 4S shop diagnostic equipment connection, automobile manufacturing plant production line testing, vehicle diagnostic system (OBD-II) development, professional automobile maintenance equipment supporting and new energy vehicle battery management system testing.

Kaweei's wire harness customization factory has IATF 16949 automotive industry quality management system certification, UL/CSA safety certification, and RoHS/REACH environmental certification. It focuses on providing customers with customized wire harness solutions. If you need customized wire harnesses, please contact us.