By quanyu lee

2025-01-13 07:13:18

Complete Guide to Waterproof Cable Assemblies: IP67/IP68, Wiring Standards

In outdoor, humid, high-temperature, or industrial environments, ordinary cables often cannot withstand moisture, dust, and mechanical impact for extended periods, leading to conductor corrosion, short circuits, and even equipment failure. Waterproof cable assemblies are designed to address these risks, ensuring stable and reliable connections under harsh conditions through sealed structures, durable materials, and standardized testing. This guide will provide a systematic understanding of how to select, design, and test waterproof cable assemblies, using actionable steps, material comparisons, and real-world experience, thereby improving equipment safety and lifespan.

I. What is a waterproof cable assembly?

A waterproof cable assembly is an electrical connection structure specifically designed for wet, rainy, outdoor, and underwater environments. Its core objective is to prevent moisture from penetrating conductors or contacts.

Its basic components include:

- Conductors (pure copper, tin-plated copper, oxide-protected copper)

- Sheath materials (TPU, PUR, TPE, XLPE)

- Connectors and sealing systems (O-ring, injection molding, threaded clamping)

- Shielding layer (EMI/interference immunity)

- Tension cushioning structure

Common application scenarios: Starlink outdoor equipment, CCTV cameras, AGV industrial vehicles, ships, solar energy systems, communication antennas, and automated machinery.

II. The Importance of Waterproof Cables

Waterproof failure is one of the most common and costly sources of malfunction for outdoor equipment.

Moisture or humidity can cause:

- Terminal corrosion

- Increased contact resistance

- Short circuit or intermittent disconnection

- Connector failure

- Sheath cracking and aging

Choosing the right waterproof cable can significantly extend equipment life, reduce maintenance costs, and improve system reliability.

III. How to select waterproof cable assemblies?

Selecting waterproof cable assemblies requires a systematic evaluation of five aspects: environment, materials, structure, electrical requirements, and certifications. The following are the complete selection steps at the engineering level:

Step 1: Determine the operating environment and protection level.

The operating environment determines the required sealing depth:

| Environment type | Recommended IP level | Illustrate |

| Rainwater, high outdoor humidity | IP67 | Can be briefly submerged in water |

| Long-term outdoor communication equipment | IP67–IP68 | Stronger water pressure resistance |

| Underwater equipment, coastal environment | IP68 | Continuous water immersion, not easily corroded |

| Food processing/rinsing equipment, industrial high-pressure water guns | IP69K | Can withstand high-pressure hot water cleaning |

Selection logic: The more exposed the device, the higher the selected IP rating and the tighter the seal.

Step 2: Select the wire gauge (AWG) and conductor material according to electrical requirements.

The amount of current and the distance will directly affect the wire gauge.

Recommended specifications:

- Small current (<5A): AWG 22–20

- Medium current (5–10A): AWG 20–18

- High current (10–20A): AWG 18–14

Recommended conductor materials:

- Tin-plated copper → High corrosion resistance, suitable for outdoor and coastal use

- Pure copper → Good conductivity

- Multi-strand fine stranded wire → More resistant to bending and vibration

The more humid the environment and the closer it is to the sea, the more tin-plated copper is needed.

Step 3: Choose the sheath material (a key factor determining lifespan)

Different materials are suitable for different environments:

| Material | Features | Recommended scenarios |

| TPU (High Abrasion Resistance) | Oil-resistant, flexible, and impact-resistant | AGV, Robot, Outdoor |

| PUR (abrasion resistant + UV resistant) | Strong UV stability | Prolonged exposure to the sun |

| TPE (soft) | Common materials, low cost | General outdoor equipment |

| XLPE (high temperature end) | Heat-resistant and anti-aging | Solar energy, cars |

If you plan to use it outdoors for an extended period, please choose a UV-resistant material; otherwise, the cover may crack prematurely.

Step 4: Select a waterproof connector structure

Common waterproof structures and their applicability:

① Injection molding encapsulation (strongest seal)

- Preferred for underwater applications

- Impartially molded structure, resistant to water ingress

- High tensile strength

② O-ring sealing structure (removable type)

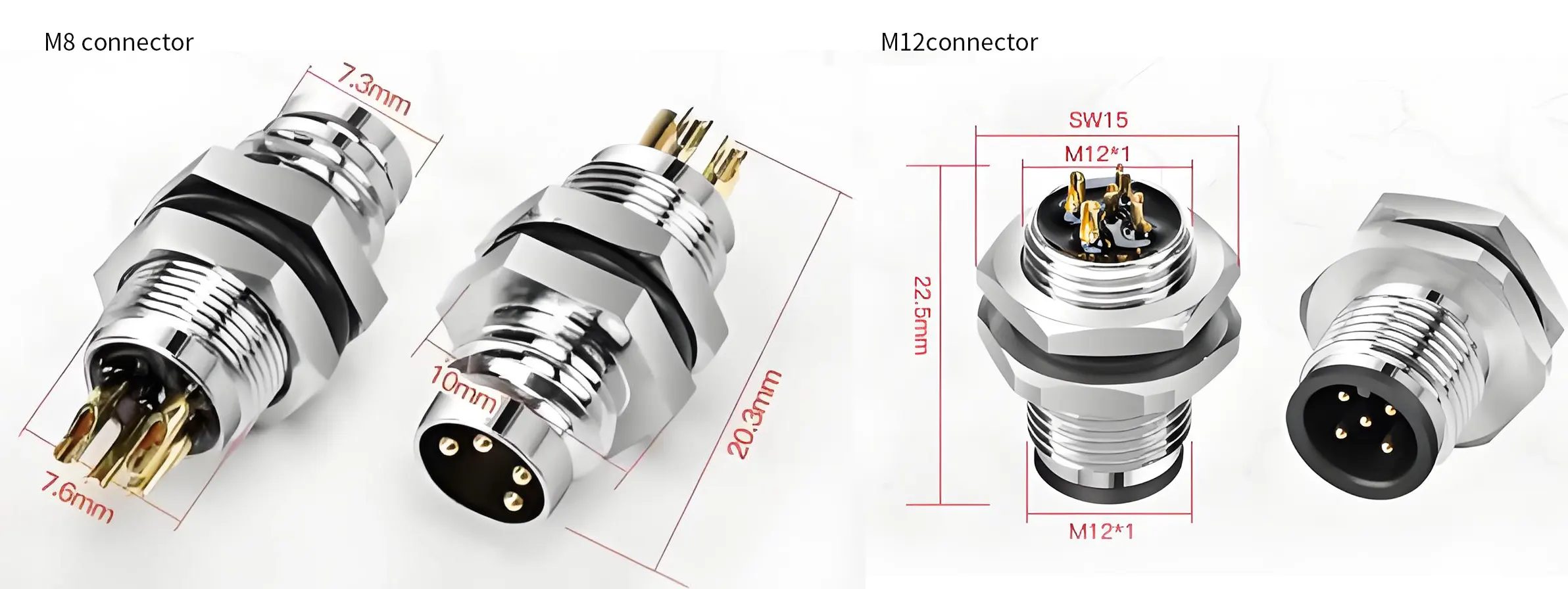

- Commonly found in M8/M12, RJ45, and DC waterproof connectors

- Easy to maintain

- However, the O-ring needs to be replaced due to long-term aging.

③ Threaded clamping structure

- Suitable for export of machinery and equipment

- Good waterproof performance

- Good seismic resistance

④ Heat shrink tubing/glue sealing (temporary solution)

- Low cost

- Unsuitable for long-term underwater use

Step 5: Confirm shielding requirements

Recommended shielding structure:

- Aluminum foil shielding

- Woven shielding layer

- Double-layer composite shielding

Applicable scenarios: Communication, motor control, sensors, and data cables.

Step 6: Check certifications and standards

Export or industrial customers typically require:

- UL / CSA

- CE / RoHS / REACH

- EN 60529 (Waterproof rating)

- ISO 16750 (Automotive electronics)

- IEC 61076 (M12/M8 standard)

Plan according to customer requirements to avoid rework.

Step 7: Conduct Necessary Tests

Any waterproof cable must be verified for the following:

- IPX7/IPX8 Waterproof Test

- Pull Test

- Hi-Pot Insulation Withstand Voltage

- Continuity Test

- Salt Spray Test (For Marine or Coastal Applications)

- UV Aging Test (Long-Term Outdoor Use)

Testing is essential to ensure mass production stability.

IV. Comparison Table of Common Waterproof Structures

| Waterproof method | Advantage | Shortcoming | Recommended scenarios |

| Injection molding | The strongest seal | High mold cost | Underwater and outdoor permanent installation |

| O-ring | Maintainable | Aging and the need to be replaced | Outdoor communications, cameras |

| Thread locking | Stable and reliable | Tools are needed for loading and unloading. | Mechanical equipment |

| Heat shrink tube | Lowest cost | Limited waterproof capability | Temporary or low-risk applications |

V. Common Mistakes

- Focusing solely on IP rating without considering material temperature resistance: Summer exposure to direct sunlight causes PVC to age rapidly; TPU or PUR is recommended.

- Inadequate wire gauge selection leads to voltage drop: Longer distances and heavier loads require thicker wire gauges.

- Detachable connectors are used in deep-water applications. Injection molding encapsulation is essential for underwater applications.

- Ignoring corrosion resistance requirements. Tin-plated copper and corrosion-resistant terminals are crucial for marine applications.

- Mass production without salt spray or UV testing. Outdoor equipment failures often stem from long-term aging, not short-term exposure.

VI. Recommendations for Professional Custom Wiring Harness Factories

Specialized manufacturers like Wire Harness Assembly offer the following when customizing waterproof cables:

- IP67/IP68 Injection Mold Development

- PUR/TPU Sheath Material Selection

- Custom Waterproof RJ45, M12, DC Connectors

- Tensile Testing, Salt Spray Testing, IPX8 Testing

- CE/UL/RoHS Reports

- Batch Consistency and Reliability Verification

Suitable for customers who need to use it outdoors or at sea for extended periods.

VII. FAQ

1. How long can waterproof cables be submerged in water?

It depends on the IP rating. IP67 is for short-term immersion, while IP68 is suitable for long-term immersion.

2. Which material is best suited for outdoor use?

PUR or TPU, which are UV-resistant, abrasion-resistant, and oil-resistant.

3. What conductor should be used near the sea?

Tin-plated copper conductors effectively prevent corrosion.

4. Are waterproof DC connectors reliable?

Yes, as long as an O-ring or injection-molded encapsulation structure is used.

5. What do I need to provide for the factory to customize?

Current, voltage, length, interface type, operating environment, whether shielding is required, etc.