By quanyu lee

2025-06-21 06:42:40

What does OBD II mean?

OBD II (On-Board Diagnostics II) is the second-generation on-board diagnostics system for light- and medium-duty vehicles. It monitors emission-related components and triggers alarms if malfunctions occur, ensuring the vehicle complies with environmental regulations.

Definition and Core Concept

OBD II (On-Board Diagnostics II) is an advanced diagnostic system integrated into a vehicle’s Electronic Control Unit (ECU). It automatically checks critical components such as:

- Fuel injection system

- Ignition system

- Catalytic converter

- Oxygen sensor

- Evaporative emission control (EVAP) system

- Other emission-related components

When a malfunction is detected, the system records a Diagnostic Trouble Code (DTC) and activates the “Check Engine” light to alert the driver.

How OBD II Works

OBD II uses a 16-pin diagnostic connector, typically located under the steering wheel. It supports multiple protocols, such as SAE J1850 and ISO 14230, enabling:

- Retrieval of fault codes (DTCs)

- Real-time sensor data monitoring

- System calibration and reset functions

This standardization greatly improves the efficiency of diagnostics and maintenance.

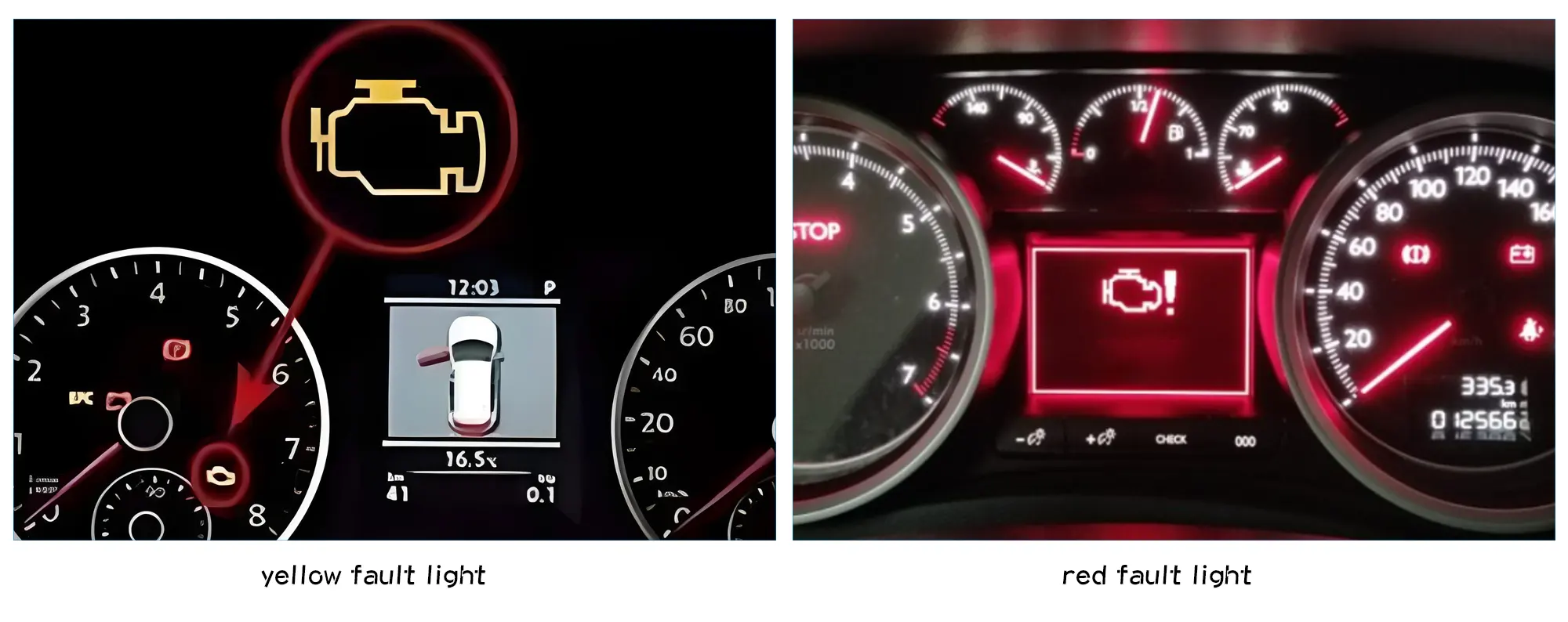

OBD II Warning Lights and Troubleshooting

- Yellow Check Engine Light – Usually indicates an emission-related issue

- Flashing or Red Light – Signals a more severe fault, possibly damaging the catalytic converter

Recommended Actions:

- Use an OBD II scanner to retrieve the error code

- Identify the faulty component

- Seek professional repair if necessary

The OBD II system integrates into the vehicle’s ECU, continuously monitoring critical components such as the fuel injection system, ignition system, catalytic converter, oxygen sensors, EVAP, and more. When a fault is detected, the system stores a Diagnostic Trouble Code (DTC) and activates the "Check Engine" light to alert the driver.

OBD II and IoT Integration

Modern OBD II systems can connect to IoT platforms, allowing:

- Remote diagnostics

- Driving behavior tracking

- Predictive maintenance alerts

With mobile apps, drivers can view real-time vehicle performance and receive instant notifications when issues occur.

Applications in Vehicle Manufacturing

OBD II relies on stable and precise wire harness connections for reliable communication between sensors and the ECU. Kaweei wire harness customization factory provides tailored vehicle wiring solutions to ensure OBD II systems operate efficiently and reliably.

OBD II vs. OBD I

| Feature | OBD I | OBD II |

| Monitoring | Limited components | Comprehensive coverage |

| Interface | Proprietary | Unified 16-pin |

| DTC System | Non-standard | Standardized codes (P0XXX/P1XXX) |

| Calibration | None | Emission-level-based |

| Data Storage | Basic | Detailed operational data |

| Warning Light | Vague or absent | Standard “Check Engine” light |

The OBD II system offers far more robust diagnostics than OBD I, with improved standardization, fault detection, and emissions calibration, addressing many limitations of the earlier system.

OBD II is more than just an emissions control system—it is the digital health monitor of modern vehicles. By providing real-time fault detection, standard diagnostic codes, and compatibility with IoT technology, OBD II ensures vehicles remain safe, efficient, and environmentally friendly.