By quanyu lee

2025-06-30 09:22:18

Jack Audio Cable for the mining industry

In the complex and harsh environment of the mining industry, reliable audio transmission is essential. Jack audio cables suitable for the mining industry are responsible for ensuring clear voice communication and accurate audio signal transmission.Our company is deeply engaged in the field of mining communication cables. With the precise matching of material science and strict control of manufacturing processes, we provide core connectors for mining equipment that have both extreme environmental resistance and stable transmission performance, ensuring "zero interruption" of data and signal transmission from the source.

Material selection: Engineering-grade standards to meet the harsh mining environment

The selection of each material is based on the extreme demands of mining scenarios. By precisely matching material properties with environmental challenges, the first line of defense for communication transmission is built.

Connector: Millimeter-level tolerance control ensures stable docking in extreme environments

Using a 7.13 four-pole precision audio connector, its core competitiveness comes from the ultimate pursuit of "connection reliability":

- Full-size tolerance locking: The diameter of the quadrupole needle is strictly controlled at 7.13mm±0.015mm (equivalent to 1/3 of the diameter of a hair), and the key dimensions of the connector outer diameter of 10.0mm and the total length of 19.5mm are 100% inspected by a three-coordinate measuring machine to ensure "zero gap" adaptation with the mining equipment interface and eliminate poor contact caused by vibration.

- Environmentally resistant material: The surface of the connector is specially plated (salt spray test for more than 500 hours), which can effectively resist corrosion and wear in high humidity and dusty environments. With high-density structural design, dust intrusion is prevented from affecting the conductive performance - this is a reliable solution verified by our 2000-hour accelerated aging test specifically for mining environments.

Wire: A Composite structure design that takes into account both transmission efficiency and mechanical durability

Select NOUL 28AWG high-performance cable, through the coordinated design of the three-layer structure of "conductor-reinforcement layer-outer-outer jacket", to achieve the dual guarantee of "no signal attenuation and physical damage resistance":

- Highly stable conductor: The conductor bundle is composed of 30/0.06TC (tinned copper wire), which is optimized by the twisting process (pitch error ≤ 0.1mm) to ensure stable signal transmission impedance (≤ 50Ω), reduce interference even in the complex electromagnetic environment of the mine, and control the data transmission rate fluctuation within ±2%.

- Anti-tensile reinforcement layer: Embedded 500D nylon wire (breaking strength ≥150N), after a dynamic fatigue test (elongation ≤3% after 10,000 stretching cycles), can withstand the instantaneous tension generated by the dragging and collision of mining equipment to avoid conductor breakage.

- Extreme environment jacket: Φ3.7mm black TPU jacket has passed low temperature elasticity test (still flexible at -40℃), wear resistance test (jacket thickness loss ≤0.1mm after 1000 frictions) and chemical resistance verification (can withstand immersion in common mining emulsions and oil for 72 hours without cracking), fully protecting against physical and chemical erosion in the mining environment.

Molding material: layered protection, building a structural integrity barrier

The "inner mold-outer mold" secondary molding process is adopted to enhance the integrated protection of connectors and cables through the complementary design of material properties:

- Inner mold (PP material): The translucent polypropylene material has been tested for heat deformation temperature (no dimensional change at 120°C) and forms a precise internal support structure after injection molding, accurately wrapping the joints and cable welding points to prevent structural loosening due to temperature fluctuations - its molding dimensional deviation is strictly controlled within ±0.05mm, and a full 3D scanning inspection is used to ensure perfect fit with internal components.

- Outer mold (TPE 90A material): An elastomer based on styrene-ethylene-butylene-styrene block copolymer (SEBS), calibrated for Shore hardness (90A±2) and tested for adhesion strength (peel force with inner mold ≥5N/cm). It has the elasticity to buffer vibration (no cracks in the structure after a 1000Hz vibration test) and provides a comfortable grip for quick plugging and unplugging operations underground.

Process control: millimeter-level precision and full-process quality control system

The core of professional manufacturing is to transform material properties into product reliability through a standardized and digitized process chain. Each step of the process is based on the principle of "traceability and verifiability".

1. Wire pretreatment: “zero damage” control from cutting to stripping

- Precision cutting: Use fully automatic laser cutting equipment (positioning accuracy ±0.05mm) to control the spring wire, connector end wire, and tail end wire within the range of 110mm±10mm, 180mm±15mm, and 320mm±15mm, respectively. The first piece of each batch must be calibrated with a length meter. During batch production, 5% of samples are taken every hour for review to ensure dimensional consistency.

- Non-destructive wire stripping: A servo-driven wire stripping machine (blade pressure adjustable range 0.1-0.5N) is used. According to the thickness difference between the TPU outer sheath and the conductor insulation layer, exclusive stripping parameters are preset (stripping depth error ≤ 0.02mm). Microscope random inspection (1 time for every 100 pieces) ensures that the insulation layer is stripped thoroughly and the conductor is not scratched - this is a key prerequisite for ensuring the conductivity of subsequent welding.

2. Welding and curing: ensuring connection reliability at the micro level

- Precision welding: Operated by technicians with IPC-A-610 welding certification, spot welding is performed using a constant temperature soldering iron (temperature controlled at 350±5℃) to ensure that the solder joint area is ≥0.5mm² and there are no cold solder joints - a tensile test is performed after each batch of welding (solder joint tensile strength ≥3N) to prevent desoldering due to vibration.

- UV glue curing: The solder joints are covered with low-viscosity UV glue (viscosity ≤ 500cP) and quickly cured by a UV curing machine (wavelength 365nm, irradiation time 10±1s) to form an insulating protective layer (insulation resistance ≥ 10¹⁰Ω). After curing, the insulation test (no breakdown under 1000V DC voltage) is required before entering the next process.

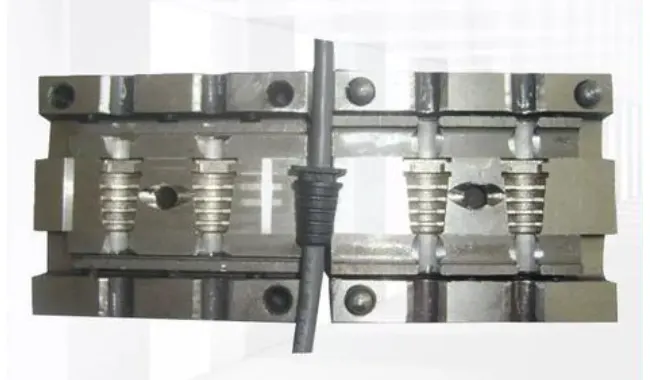

3. Secondary molding: Stability control of parameter curing

- Inner mold injection: Use a precision injection molding machine (clamping force 500kN) to inject PP material into the mold cavity at a barrel temperature of 220±2℃ and an injection pressure of 28±1bar. The mold temperature monitoring system (temperature difference ≤±1℃) ensures that the inner mold molding density is uniform (bubble-free rate 100%), and the size is inspected after molding (key position tolerance ≤±0.03mm).

- External mold injection molding: Based on the internal mold, TPE 90A is injected at a barrel temperature of 178±2℃ and an injection pressure of 25±1bar. Real-time monitoring is performed by a pressure sensor (fluctuation range ≤±0.5bar) to avoid flash or glue shortage. After molding, a full appearance inspection (no shrinkage marks, no scratches) and a Shore hardness test (to ensure that the elasticity meets the standard) are carried out.

Tail-end SR molding: structural reinforcement of anti-bending performance

Stress relief (SR) molding is performed at 50mm from the end of the cable, and a special mold (corner radius R2.5mm) is used to inject TPE material to form a gradual stress buffer structure. After molding, it passes the bending test (180° reciprocating bending 1000 times, bending radius 20mm) and the tension test (withstanding 5KG tension for 5 minutes, cable displacement ≤1mm) to ensure that the cable and connector connection will not break due to stress concentration in scenarios such as miners dragging and equipment moving.

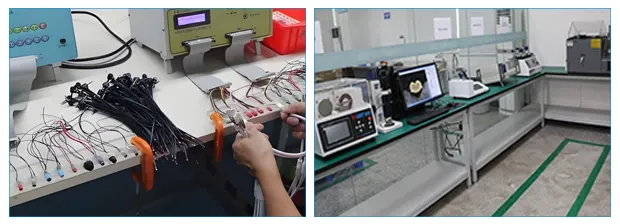

Full inspection process: the last safety gate before leaving the factory

- Conductivity test: Each product is tested by a four-wire continuity tester (test accuracy ±0.1Ω) to ensure that the conduction resistance between the quadrupole needle and the corresponding conductor is ≤0.1Ω, and there is no short circuit or open circuit.

- Environmental simulation test: 3% of the products in each batch are randomly selected for comprehensive environmental testing (-40℃ to 85℃ high and low temperature cycle 10 times, humidity 95% RH for 24 hours), and the continuity test is performed again after the test to ensure the performance stability in extreme environments.

Application value: Make every transmission stand the test of an extreme environment

In the core communication links of underground mines, such as intercoms and monitoring equipment, our cables solve practical pain points through the following features:

- Vibration resistance: After a 10-2000Hz sweep frequency vibration test (acceleration 10g), the signal transmission attenuation is ≤1%, which is suitable for the continuous vibration of mining machinery;

- Chemical corrosion resistance: After immersion in emulsions and acidic water commonly used in mining for 30 days, the outer sheath does not swell, and the conductor resistance change rate is ≤5%.

- Long life guarantee: Through the MTBF (mean time between failures) test, the service life in the mining environment is ≥5 years, which is far higher than the industry average.

From the engineering-level selection of materials to the millimeter-level control of processes, from the special inspection of a single process to the quality traceability of the entire process, Kaweei's wire harness customization factory uses "professional manufacturing" to ensure the communication security of the mining industry. Because we are well aware that thousands of meters underground, the reliability of each cable crafted by Kaweei carries the lives of miners and the peace of mind of their work.